Unlocking the Potential of Air-Cooled Heat Exchangers with Artificial Intelligence

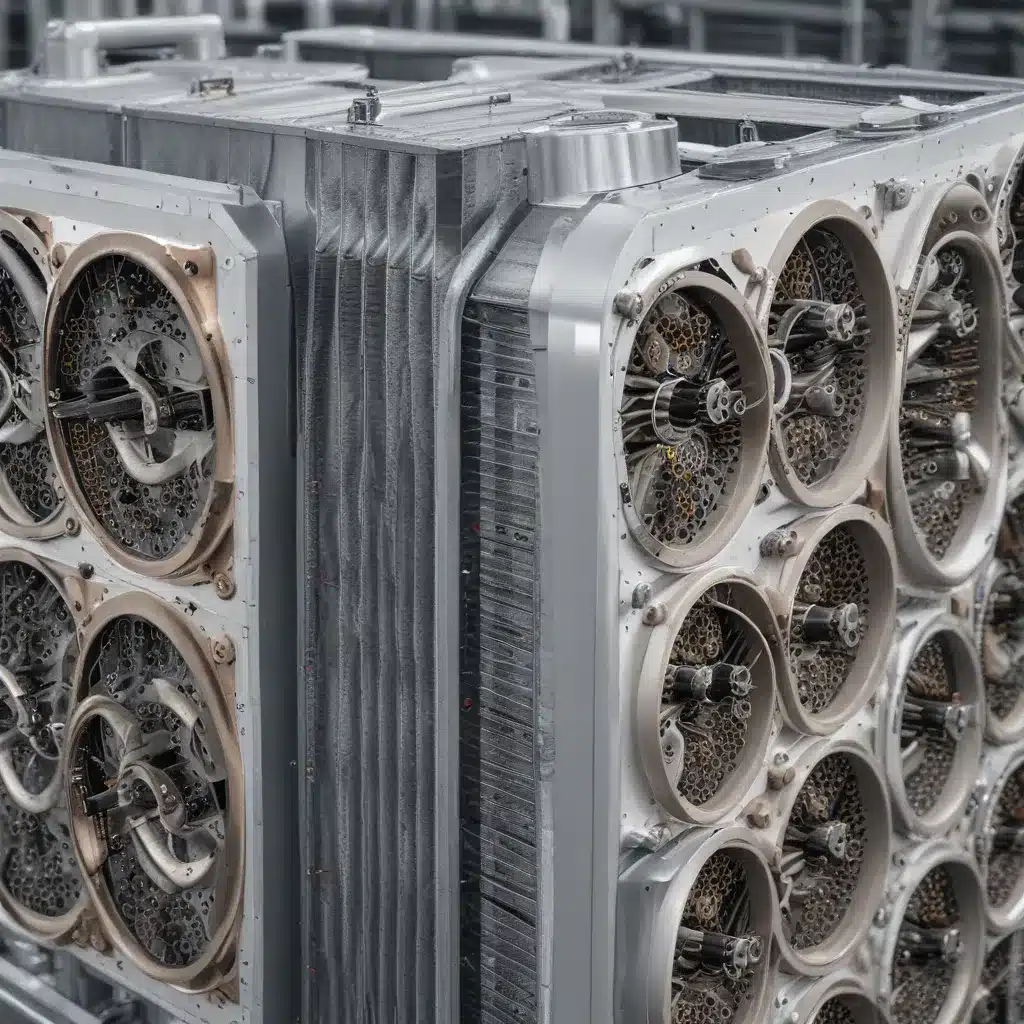

In the rapidly evolving landscape of modern industry, the efficient management of thermal loads has become a critical imperative. Air-cooled heat exchangers, long-standing workhorses in a vast array of applications, are now poised to undergo a transformative evolution through the integration of machine learning (ML) technologies. By harnessing the power of AI-driven insights, we can unlock new levels of performance, optimization, and predictive maintenance for these essential heat transfer systems.

Revolutionizing Heat Exchanger Design and Performance

Traditionally, the design and optimization of air-cooled heat exchangers have relied heavily on empirical knowledge, experimental data, and engineering intuition. While this approach has served industries well, it often falls short in capturing the nuanced interplay of complex variables that influence heat exchanger performance. Machine learning techniques offer a game-changing solution, enabling us to uncover hidden patterns, predict critical thresholds, and fine-tune design parameters with unprecedented precision.

By training ML models on vast repositories of operational data, design specifications, and environmental factors, we can develop predictive algorithms that can guide the design process. These algorithms can help engineers identify the most influential parameters, optimize fin geometries, and select the optimal materials to maximize heat transfer efficiency, minimize pressure drop, and reduce energy consumption. The integration of ML-driven simulations into the design workflow can drastically accelerate the iterative process, allowing for the exploration of a broader design space and the identification of innovative solutions that traditional methods may have overlooked.

Moreover, ML-powered digital twins can replicate the behavior of air-cooled heat exchangers with remarkable accuracy, enabling us to test and validate performance under a wide range of operating conditions without the need for physical prototypes. This approach not only streamlines the development cycle but also unlocks opportunities for personalized optimization, where the digital twin can be tailored to the unique characteristics of a specific installation, considering factors such as local climate, process requirements, and integration with broader system architectures.

Enhancing Operational Efficiency through Predictive Maintenance

Air-cooled heat exchangers, like any critical industrial equipment, require vigilant maintenance to ensure reliable and efficient operation. Traditionally, maintenance strategies have relied on time-based or reactive approaches, leading to unnecessary downtime, excessive costs, and the risk of unexpected failures. Machine learning offers a transformative solution to this challenge, empowering us to transition towards predictive maintenance strategies.

By leveraging sensor data from air-cooled heat exchangers, ML algorithms can detect subtle shifts in performance indicators, such as changes in pressure drop, vibration patterns, or heat transfer rates. These early warning signs can then be used to predict the onset of potential failures, allowing maintenance teams to take proactive measures before problems escalate. This predictive approach not only reduces unplanned downtime but also optimizes the utilization of maintenance resources, ensuring that interventions are precisely targeted and cost-effective.

Furthermore, ML-based anomaly detection can help identify deviations from normal operating parameters, enabling operators to swiftly address issues before they impact overall system performance. This enhanced situational awareness can lead to better-informed decision-making, improved asset life-cycle management, and more efficient resource allocation.

Optimizing Air-Cooled Heat Exchanger Applications

The versatility of air-cooled heat exchangers extends across a wide range of industries, from power generation and manufacturing to data centers and HVAC systems. In each of these diverse applications, the integration of machine learning can yield significant benefits.

In power plants, for instance, ML-powered optimization algorithms can help fine-tune the performance of air-cooled condensers, ensuring optimal heat rejection and maximizing the overall efficiency of the power generation cycle. Similarly, in industrial manufacturing settings, ML models can be leveraged to adjust air-cooled heat exchanger parameters in response to changing process conditions, maintaining the optimal temperature and humidity levels required for product quality and safety.

The rise of data centers and the growing demand for high-performance computing have further highlighted the importance of effective cooling solutions. Rear Door Heat Exchangers (RDHx), like Motivair’s ChilledDoor®, have emerged as a game-changing technology in this context, providing targeted cooling at the server rack level. By integrating ML-driven controls and predictive maintenance into these RDHx systems, data center operators can achieve remarkable improvements in energy efficiency, thermal management, and overall system reliability.

Toward a Sustainable Future with Intelligent Heat Exchangers

As the world grapples with the urgent need for sustainable and energy-efficient solutions, the integration of machine learning into air-cooled heat exchanger technology holds immense promise. By optimizing the design, operation, and maintenance of these essential systems, we can unlock significant reductions in energy consumption, greenhouse gas emissions, and overall environmental impact.

Moreover, the insights gleaned from ML-powered analytics can guide the development of next-generation heat exchanger designs, leveraging novel materials, advanced geometries, and intelligent control algorithms to push the boundaries of thermal management efficiency. As we strive to meet the challenges of a rapidly evolving industrial landscape, the symbiosis of air-cooled heat exchangers and machine learning will undoubtedly play a pivotal role in shaping a more sustainable and technologically advanced future.

Conclusion: Embracing the AI-Powered Future of Air-Cooled Heat Exchangers

The integration of machine learning into the realm of air-cooled heat exchangers represents a transformative shift in the way we approach thermal management challenges. By harnessing the power of AI-driven insights, we can unlock unprecedented levels of performance, optimization, and predictive maintenance, empowering industries to navigate the complexities of the modern world with greater efficiency, reliability, and environmental responsibility.

As we continue to push the boundaries of what is possible, the future of air-cooled heat exchangers promises to be both exciting and transformative. By embracing this AI-powered evolution, we can unlock new avenues for innovation, enhance the overall resilience of our critical infrastructure, and contribute to the creation of a more sustainable and technologically advanced future.

To learn more about the latest advancements in air-cooled heat exchanger technology, please visit https://www.aircooledheatexchangers.net/.