Harnessing Nature’s Efficiency for Advanced Thermal Management

Air-cooled heat exchangers are essential equipment across various industries, playing a crucial role in energy efficiency and process optimization. As we face the challenge of diminishing fossil fuel reserves, enhancing the performance of these heat exchangers has become increasingly important. One promising approach is to draw inspiration from the natural world, leveraging the remarkable adaptations and structures found in nature to improve heat transfer and reduce flow resistance.

Biomimetic Structures for Enhanced Heat Transfer

The natural world is teeming with ingenious solutions to thermal management challenges. From the fractal-like branching patterns of tree leaves to the water-repellent properties of lotus leaves, nature has evolved a vast array of structures and mechanisms that excel at regulating heat and fluid flow. By studying these biomimetic designs and replicating their key features, engineers can develop innovative air-cooled heat exchanger technologies that outperform traditional designs.

Fractal-Tree-Like Heat Exchangers

One of the most striking examples of nature’s efficiency is the fractal-like branching patterns observed in natural structures, such as tree leaves, blood vessels, and lung alveoli. Researchers have applied these fractal principles to the design of heat exchanger channels, creating tree-like branching networks that mimic the efficient distribution and collection of fluids in biological systems. These fractal-tree-like heat exchangers have been shown to enhance heat transfer performance while reducing pressure drop, making them well-suited for applications where compact size and high energy efficiency are priorities.

Key factors that influence the performance of fractal-tree-like heat exchangers include the number and angle of the branches, the aspect ratio of the channels, and the overall layer structure. By carefully optimizing these parameters, engineers can tailor the heat exchanger design to specific thermal management needs, unlocking new levels of efficiency.

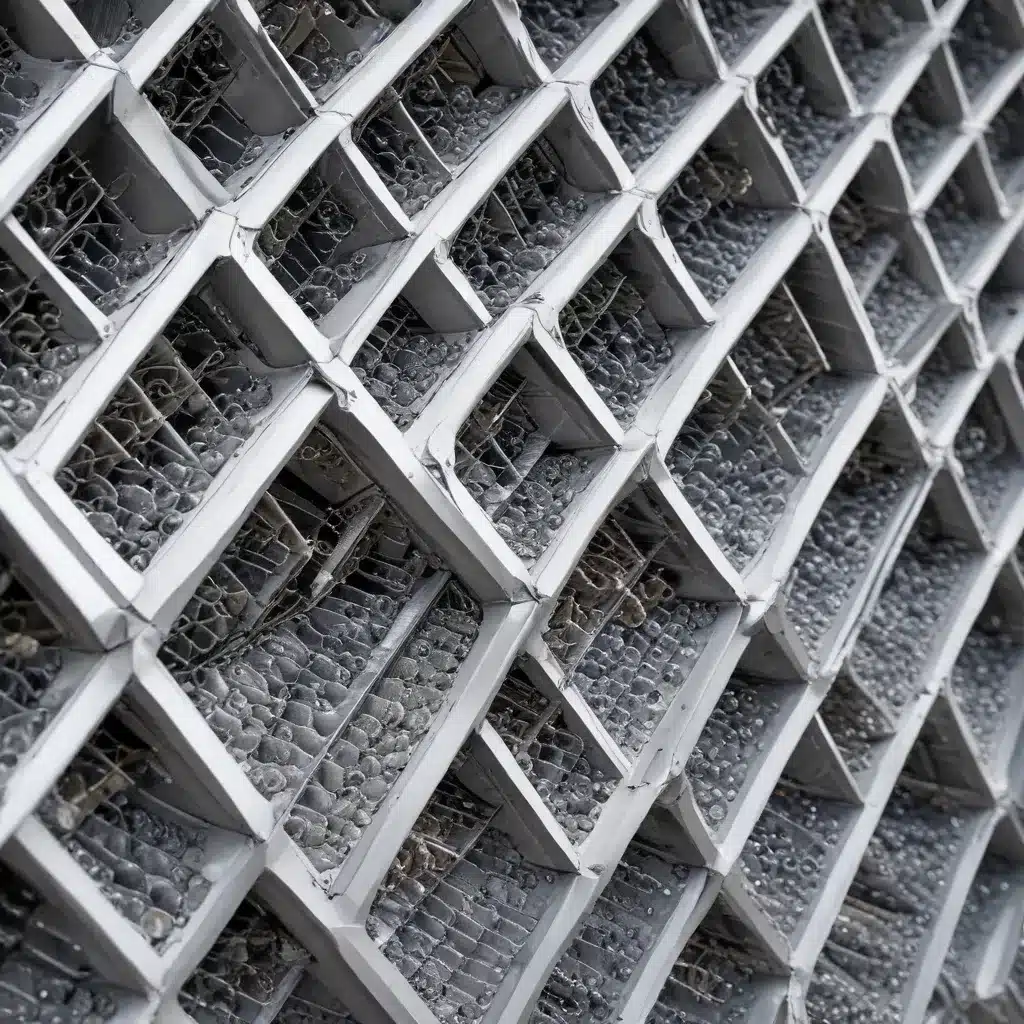

Biomimetic Condensation Surfaces

Condensation is a ubiquitous phase change process that is crucial to the performance of many air-cooled heat exchangers. Nature has developed highly effective strategies for managing condensation, such as the water-repellent surfaces of lotus leaves and the self-cleaning mechanisms of cicada wings.

Researchers have studied these natural phenomena and applied them to the design of heat exchanger surfaces, creating biomimetic structures that promote efficient droplet formation, removal, and transport. For example, the conical column structures found on the leaves of Lychnis sibirica and the spiny surfaces of cacti have inspired the development of superhydrophobic coatings that enhance dropwise condensation and reduce flow resistance.

Furthermore, the hybrid wetting surfaces observed in nature, such as the water-collecting structures on the backs of Namib desert beetles, have been replicated to create heat exchanger surfaces with optimized wettability. By strategically controlling the distribution of hydrophilic and hydrophobic regions, these biomimetic surfaces can effectively manage the condensation process, leading to improved heat transfer performance.

Drag-Reducing Biomimetic Surfaces

In addition to enhancing heat transfer, biomimetic structures can also play a crucial role in reducing the flow resistance encountered in air-cooled heat exchangers. Many organisms in nature have evolved surface features that enable them to move efficiently through their respective environments, and engineers have sought to replicate these adaptations.

One prominent example is the shark skin, which features a unique grooved texture that reduces drag. Inspired by this natural design, researchers have developed biomimetic surfaces with grooves, dimples, and other non-smooth features that can effectively disrupt the flow patterns near the surface, leading to significant reductions in viscous drag and form drag.

Similarly, the scale structures of fish, such as those found on the grass carp, have been studied and replicated in the design of micro-structured surfaces for heat exchangers. These biomimetic surfaces have demonstrated the ability to reduce flow resistance, further improving the overall efficiency of air-cooled heat exchanger systems.

Biomimetic Surface Fabrication Techniques

The realization of biomimetic structures in air-cooled heat exchangers requires the use of advanced micro- and nano-scale manufacturing techniques. Several key fabrication methods have emerged as effective tools for creating these intricate surface features:

Photolithography

Photolithography is a versatile technique that uses photochemical reactions and selective material removal to produce high-precision micro- and nano-scale structures. This method has been employed to fabricate a variety of biomimetic surface features, such as the inclined arc-pitted grooves inspired by the curved outline of Nepenthes alata and the hydrophilic-hydrophobic composite structures mimicking the Namib desert beetle.

Nanoimprinting

Nanoimprinting leverages the traditional mold-replication technique to transfer complex micro- and nano-scale patterns onto target surfaces. This process has been used to replicate the cylindrical array structures found on cicada wings, as well as the hierarchical micro-nano structures observed on lotus leaves and butterfly wings.

Femtosecond Laser Processing

Femtosecond laser processing utilizes ultrashort, high-intensity pulses to selectively remove material and create intricate surface features. This technique has been employed to fabricate biomimetic structures inspired by fish scales and lotus leaves, resulting in hierarchical micro-nano rough surfaces with tailored wettability.

3D Printing

The rapid advancement of 3D printing technology has made it possible to fabricate biomimetic structures with increasing complexity and precision. Researchers have leveraged 3D printing to create synthetic shark skin membranes and artificial micro-hairs inspired by the Salvinia molesta leaf, demonstrating the versatility of this additive manufacturing approach.

By combining these cutting-edge fabrication methods, engineers can design and produce a wide range of biomimetic surface structures, tailoring the features to optimize the performance of air-cooled heat exchangers for specific applications and operating conditions.

The Future of Biomimetic Heat Exchanger Design

As the field of biomimetics continues to advance, the potential for enhancing air-cooled heat exchanger performance through nature-inspired designs is vast and promising. Future developments in this area are likely to focus on several key areas:

-

Integrated Biomimetic Structures: Researchers will explore the synergistic effects of combining multiple biomimetic features, such as integrating fractal-tree-like channel networks with drag-reducing surface textures or self-cleaning condensation-enhancing coatings. This holistic approach has the potential to unlock unprecedented levels of efficiency.

-

Advanced Biomimetic Materials: The development of novel materials and composites that mimic the unique properties of natural structures, such as the lightweight strength of spider silk or the thermal regulation capabilities of polar bear fur, will enable the creation of even more advanced and adaptive heat exchanger components.

-

Smart, Self-Regulating Systems: Biomimetic HVAC systems that can autonomously adjust their performance based on environmental conditions and occupancy needs, similar to how natural organisms dynamically adapt to their surroundings, will become increasingly prevalent. These intelligent, responsive systems will optimize energy consumption and indoor climate control.

-

Sustainable, Eco-Friendly Solutions: As the global focus on environmental sustainability intensifies, biomimetic heat exchanger designs that minimize energy use, reduce emissions, and promote the use of renewable, biodegradable materials will become essential for meeting the challenges of a greener future.

By continuing to draw inspiration from nature’s ingenious solutions, the future of air-cooled heat exchanger technology promises to be more efficient, resilient, and environmentally responsible than ever before. As an expert in this field, I am excited to see how biomimetic innovations will transform the way we approach thermal management challenges across diverse industries.