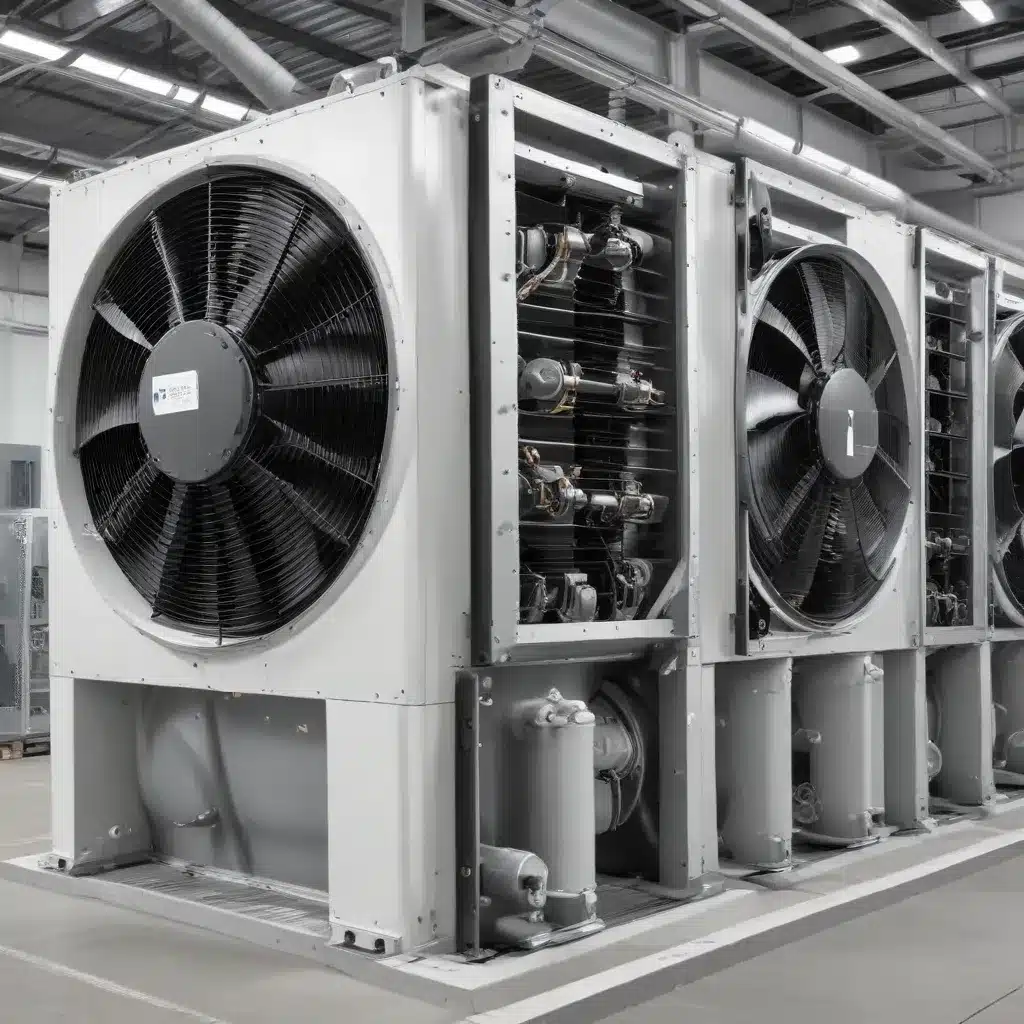

Understanding the Importance of Air-Cooled Heat Exchangers

Air-cooled heat exchangers play a crucial role in various industries, from power generation to industrial manufacturing. These versatile systems efficiently transfer thermal energy between a process fluid and the surrounding air, allowing for effective cooling or heating without relying on water-based systems. Their widespread use is a testament to their reliability, cost-effectiveness, and adaptability in a wide range of applications.

However, maximizing the efficiency of air-cooled heat exchangers can be a complex challenge. Factors such as fluctuating ambient conditions, varying process loads, and the inherent limitations of traditional control systems can all contribute to suboptimal performance and energy consumption. To address these challenges, the integration of intelligent fan control and automation technologies has emerged as a game-changing solution, offering a path to enhanced efficiency, energy savings, and improved overall system reliability.

The Benefits of Intelligent Fan Control

Conventional air-cooled heat exchangers often rely on simple on/off or manual fan control strategies, which can lead to inefficient operation and missed opportunities for energy optimization. Intelligent fan control systems, on the other hand, utilize advanced sensors, algorithms, and control logic to dynamically adjust fan speed and operation based on real-time process and environmental conditions.

Key benefits of intelligent fan control include:

-

Improved Energy Efficiency: By precisely matching fan speed to the actual cooling or heating demand, intelligent control systems can significantly reduce energy consumption, leading to lower operating costs and a smaller carbon footprint.

-

Enhanced Process Stability: Intelligent fan control can maintain tighter temperature control within the heat exchanger, ensuring more consistent and reliable process performance, even in the face of fluctuating ambient conditions or process loads.

-

Reduced Maintenance and Downtime: Intelligent control systems can monitor fan and system performance, detecting potential issues before they escalate into costly failures. This proactive approach can extend equipment lifespan and minimize unplanned downtime.

-

Increased Operational Flexibility: Intelligent control allows for the integration of advanced features, such as remote monitoring, predictive maintenance, and adaptability to changing process requirements, making air-cooled heat exchangers more versatile and responsive to evolving needs.

Automating Air-Cooled Heat Exchanger Operations

Integrating automation technologies with air-cooled heat exchanger systems can further enhance efficiency, reliability, and ease of management. Automation solutions leverage sensors, data analytics, and control algorithms to optimize the performance of these critical components, often in conjunction with intelligent fan control.

Key automation features and benefits include:

-

Automated Control and Optimization: Automation systems can continuously monitor and adjust fan speed, damper positions, and other parameters to maintain optimal heat transfer while minimizing energy consumption.

-

Predictive Maintenance and Diagnostics: Automation platforms can collect and analyze operational data, enabling predictive maintenance strategies that anticipate potential issues and schedule proactive maintenance, reducing unplanned downtime.

-

Remote Monitoring and Control: Automation systems can provide remote access and control capabilities, allowing operators to monitor performance, make adjustments, and troubleshoot issues from any location, improving efficiency and responsiveness.

-

Integrated System Optimization: By coordinating the operation of air-cooled heat exchangers with other process equipment, automation systems can enhance overall system efficiency and performance, optimizing energy use and process outcomes.

-

Increased Visibility and Data-Driven Decisions: Automation platforms gather extensive operational data, which can be leveraged to generate valuable insights, identify optimization opportunities, and make more informed, data-driven decisions about asset management and process improvements.

Designing for Optimal Air-Cooled Heat Exchanger Performance

Achieving the full benefits of intelligent fan control and automation requires a holistic approach to air-cooled heat exchanger design and engineering. Careful consideration of factors such as airflow management, materials selection, and integration with broader system requirements can further enhance the efficiency and reliability of these critical components.

Design considerations and best practices include:

-

Airflow Optimization: Streamlining the air inlet and outlet, utilizing computational fluid dynamics (CFD) analysis, and optimizing fan and baffle designs can improve airflow patterns and heat transfer efficiency.

-

Material Selection: Choosing the right materials for heat exchanger tubes, fins, and structural components can impact corrosion resistance, thermal conductivity, and overall operational lifetime.

-

Integration with Process Requirements: Aligning the heat exchanger’s design and performance characteristics with the specific process needs, such as required heat transfer rates, pressure drops, and space constraints, can ensure optimal integration and efficiency.

-

Modular and Scalable Architectures: Designing air-cooled heat exchangers with modular and scalable approaches can facilitate easy retrofitting, expansions, and adaptations to changing process demands.

-

Maintenance and Accessibility: Incorporating features that simplify maintenance, inspection, and cleaning, such as easy-to-access components and robust corrosion-resistant coatings, can enhance the long-term reliability and performance of the system.

By addressing these design considerations and leveraging intelligent fan control and automation technologies, air-cooled heat exchanger systems can achieve new levels of efficiency, reliability, and responsiveness, delivering significant operational and financial benefits across a wide range of industries.

Case Study: Optimizing Turbine Cooling with Automated Air-Cooled Heat Exchangers

In the power generation industry, air-cooled heat exchangers play a critical role in cooling turbine lubricating oil and generator cooling circuits. One notable example is the TOMONI™ Turbine Cooling Air Optimization solution from Mitsubishi Heavy Industries, which combines intelligent fan control and automation to enhance the efficiency and reliability of these critical cooling systems.

The TOMONI™ system utilizes advanced sensors, control algorithms, and predictive analytics to continuously optimize the operation of air-cooled heat exchangers. By dynamically adjusting fan speed and other parameters based on real-time process conditions and environmental factors, the system can maintain optimal cooling performance while significantly reducing energy consumption and maintenance requirements.

Through this automated approach, power generation facilities have achieved remarkable results, including:

- Energy Savings: Reductions in fan energy consumption of up to 40% compared to conventional control strategies.

- Improved Reliability: Proactive maintenance and diagnostics have reduced unplanned downtime by up to 30%.

- Enhanced Process Stability: Tighter temperature control has led to more consistent turbine and generator performance, ensuring reliable power generation.

- Reduced Maintenance Costs: Predictive maintenance capabilities have extended equipment lifespan and minimized the need for unscheduled repairs.

The success of the TOMONI™ Turbine Cooling Air Optimization solution demonstrates the transformative potential of intelligent fan control and automation in enhancing the efficiency and reliability of air-cooled heat exchangers, ultimately improving overall plant performance and profitability.

Embracing the Future of Air-Cooled Heat Exchanger Efficiency

As the demand for energy efficiency, process reliability, and sustainable operations continues to grow, the integration of intelligent fan control and automation technologies has emerged as a critical enabler for air-cooled heat exchanger systems. By optimizing fan operation, automating control, and leveraging predictive maintenance, these advanced solutions can unlock significant benefits in terms of energy savings, improved process stability, and enhanced equipment longevity.

The experts at Air-Cooled Heat Exchangers are dedicated to helping organizations harness the power of these transformative technologies. Through in-depth engineering expertise, data-driven insights, and customized implementation strategies, they can guide you in designing, upgrading, and optimizing your air-cooled heat exchanger systems to achieve new levels of efficiency, reliability, and overall performance.

Embrace the future of air-cooled heat exchanger technology and unlock the full potential of your critical cooling and heating systems. Contact us today to learn more about how intelligent fan control and automation can enhance your operations.