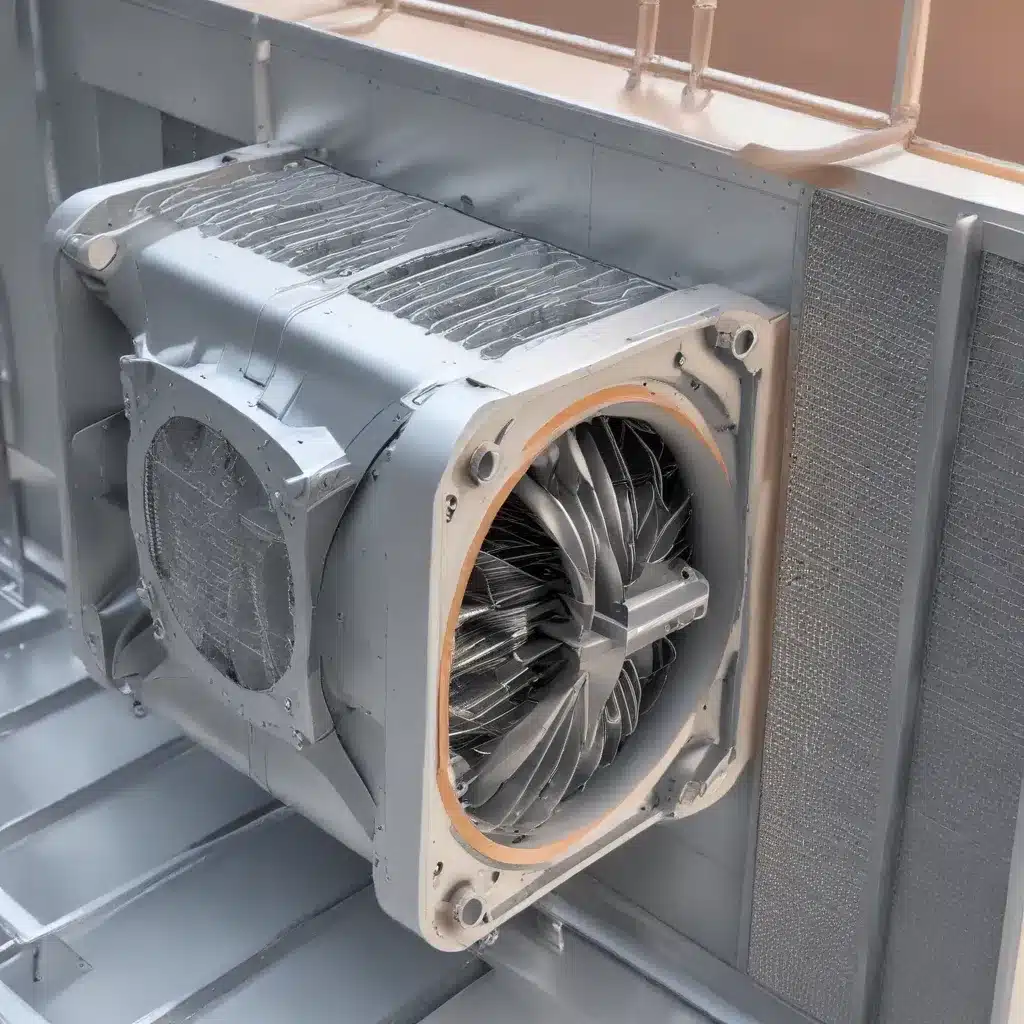

In the rapidly evolving world of industrial engineering, the pursuit of energy efficiency and sustainable practices has never been more crucial. At the heart of this mission lies the air-cooled heat exchanger, a ubiquitous yet vital component that plays a critical role in various industries, from chemical processing to power generation. As engineers strive to optimize the performance and reliability of these heat exchangers, the integration of advanced simulation and modeling tools has emerged as a game-changing strategy.

Harnessing the Power of Computational Fluid Dynamics (CFD)

One of the most transformative advancements in heat exchanger design has been the rise of Computational Fluid Dynamics (CFD) analysis. CFD allows engineers to create detailed, virtual models of fluid flow and heat transfer within complex heat exchanger geometries. By simulating real-world operating conditions, CFD provides invaluable insights into the intricate behavior of air and fluid dynamics within the exchanger, leading to several key benefits:

-

Reduced Development Time and Costs: CFD simulations enable engineers to test and evaluate multiple design iterations virtually, without the need for costly physical prototypes. This accelerates the design process and minimizes the risk of costly modifications during the final production phase.

-

Improved Understanding of Flow Patterns and Thermal Behavior: CFD analysis provides a comprehensive visualization of temperature distributions, pressure drops, and flow patterns within the heat exchanger. This enhanced understanding allows for targeted optimization of the design to maximize heat transfer efficiency.

-

Enhanced Visualization and Troubleshooting: The detailed 3D simulations generated by CFD tools offer a clear, visual representation of the heat exchanger’s performance, making it easier for engineers to identify and address potential issues or bottlenecks.

Finite Element Analysis (FEA) for Structural Integrity

Alongside the advancements in fluid dynamics, Finite Element Analysis (FEA) has emerged as a crucial tool in the design and optimization of air-cooled heat exchangers. FEA enables engineers to assess the structural integrity and thermal performance of the exchanger’s components, such as tubes, tubesheets, and shells, under realistic operating conditions.

By simulating factors like pressure, temperature, and thermal expansion, FEA helps identify potential failure points and ensures the heat exchanger can withstand various external loads, such as vibration or seismic activity. This analysis is particularly valuable in ensuring the long-term reliability and safety of air-cooled heat exchangers, especially in mission-critical applications.

Furthermore, FEA aids in the evaluation of material usage, allowing engineers to optimize the design for cost-effectiveness without compromising performance or structural integrity. This holistic approach to heat exchanger design, incorporating both fluid dynamics and structural analysis, is crucial in delivering robust, efficient, and cost-effective solutions.

Harnessing Industry-Leading Simulation Software

The advent of specialized software tools has been instrumental in unlocking the full potential of advanced simulation and modeling techniques for air-cooled heat exchangers. Industry-leading platforms, such as HTRI Xist and HTRI XACE, have been specifically designed to address the unique challenges faced by engineers in this domain.

HTRI Xist: This powerful software tool is dedicated to the thermal and hydraulic analysis of shell-and-tube heat exchangers, a common configuration in industrial applications. Xist leverages a vast database of empirical correlations and real-world data, gathered through decades of research and field testing, to provide accurate predictions of heat transfer rates, pressure drops, and overall efficiency.

HTRI XACE: For air-cooled heat exchangers, the XACE software solution offers a specialized tool for design, rating, and optimization. It considers factors like airflow distribution, fan performance, and finned tube arrangements, enabling engineers to evaluate and enhance the exchanger’s effectiveness under varying operating conditions.

These industry-leading simulation tools empower engineers to optimize the performance, reliability, and cost-effectiveness of their air-cooled heat exchanger designs, ultimately contributing to the overall efficiency and sustainability of industrial processes.

Advancing Material Simulation and Optimization

In addition to the advancements in fluid dynamics and structural analysis, simulation tools have also revolutionized the way engineers approach material selection and optimization for air-cooled heat exchangers.

Mersen, a global leader in industrial solutions, offers a suite of material property simulation tools that enable the modeling of advanced materials, such as graphite and composites, under various conditions, including temperature, pressure, and stress. These simulations help in optimizing the material properties for specific applications, ensuring that the materials perform reliably and efficiently in real-world conditions.

By leveraging these innovative simulation tools, engineers can make informed decisions on material selection, tailoring the heat exchanger’s construction to the unique demands of their industry or application. This level of precision and customization is crucial in achieving the desired performance, longevity, and cost-effectiveness of air-cooled heat exchangers.

Optimizing Air-Cooled Heat Exchanger Design

Beyond the individual advancements in simulation and modeling techniques, the integration of these tools into a comprehensive design workflow has unlocked new levels of optimization for air-cooled heat exchangers.

Engineers can now seamlessly combine CFD, FEA, and specialized software solutions to address the complex trade-offs between thermal performance, structural integrity, and material costs. Advanced multi-objective optimization algorithms help identify the best compromise solutions, ensuring that the final design not only meets the desired performance criteria but also aligns with the specific requirements and constraints of the project.

This holistic approach to air-cooled heat exchanger design, enabled by the effective integration of simulation and modeling tools, has a far-reaching impact on the industry. It allows engineers to:

- Enhance energy efficiency and reduce operational costs

- Improve reliability and extend the lifespan of heat exchangers

- Minimize the environmental impact through optimized material usage and reduced energy consumption

- Accelerate the development process and bring innovative solutions to market more quickly

Empowering the Future of Air-Cooled Heat Exchangers

As the world continues to demand ever-greater efficiency and sustainability, the role of air-cooled heat exchangers will only become more critical. By embracing the power of advanced simulation and modeling tools, engineers can unlock new levels of innovation and optimization, driving the air-cooled heat exchanger industry forward and contributing to a more sustainable future.

At the Air Cooled Heat Exchangers blog, we are committed to empowering our readers with the latest insights, practical tips, and industry-leading expertise on the design, engineering, and maintenance of these vital components. Stay tuned for more in-depth articles and resources that will help you navigate the ever-evolving landscape of air-cooled heat exchanger technology.