Optimizing Air-Cooled Heat Exchanger Design and Performance

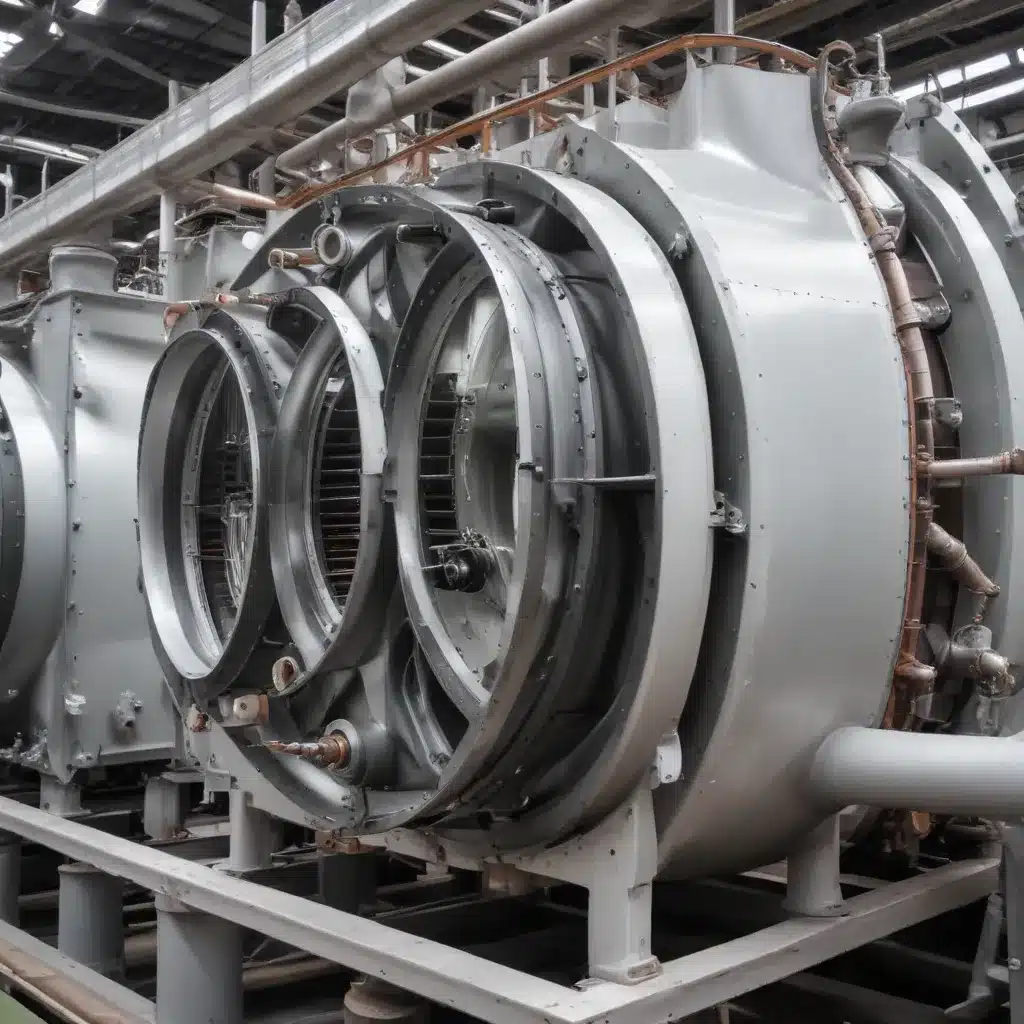

Air-cooled heat exchangers (ACHEs) play a crucial role in thermal management across various industries, including petrochemicals, oil and gas, power generation, and data centers. These systems effectively transfer heat from a process fluid to the surrounding air, making them an essential component in industrial operations where efficient cooling and heating are paramount. As the global demand for sustainable, cost-effective, and reliable thermal management solutions continues to grow, it is vital to explore the latest advancements in ACHE design, materials, and performance optimization techniques.

Understanding the Fundamentals of Air-Cooled Heat Exchangers

At the core of an ACHE is the principle of heat transfer, where thermal energy is transported from a hotter fluid to a cooler fluid (in this case, air) through a solid barrier, such as metal tubes or fins. The heat transfer process involves three primary mechanisms: conduction through the solid barrier, convection within the fluids, and sometimes radiation in high-temperature environments.

ACHEs come in various configurations, including forced draft, induced draft, and non-ducted designs, each offering unique advantages based on the specific application requirements. Forced draft systems use fans to actively draw air across the heat exchanger, while induced draft designs employ fans to create a low-pressure environment that pulls air through the unit. Non-ducted ACHEs, on the other hand, rely on natural convection and are often more compact and cost-effective.

The choice of fin design is another critical factor in ACHE performance. Common options include plain fins, louvered fins, and extruded fins, each with its own strengths in terms of heat transfer efficiency, fouling resistance, and compactness.

Enhancing Thermal Efficiency through Material Selection

The materials used in ACHE construction play a significant role in determining the system’s thermal performance, durability, and cost-effectiveness. Stainless steel is a popular choice due to its excellent corrosion resistance, high-temperature stability, and favorable thermal conductivity. Compared to carbon steel, stainless steel ACHEs offer improved longevity and reduced maintenance requirements, making them well-suited for harsh industrial environments.

Aluminum is another material commonly used in ACHE applications, particularly in HVAC systems and automotive radiators, due to its lightweight and good thermal conductivity. Copper is also a viable option, offering exceptional heat transfer capabilities, though it may be more susceptible to corrosion in certain environments.

When selecting the optimal material for a specific ACHE application, factors such as operating conditions, environmental factors, and cost considerations must be carefully balanced to ensure the system’s long-term performance and reliability.

Optimizing Air-Cooled Heat Exchanger Design for Improved Efficiency

Enhancing the design of air-cooled heat exchangers can lead to significant improvements in thermal efficiency and overall system performance. One such approach is the implementation of advanced fin designs, such as extruded fins, which offer increased surface area for heat transfer and better fluid mixing, resulting in enhanced heat exchange rates.

Another design strategy focuses on improving air flow management, which is crucial for maximizing heat transfer. This can be achieved through the use of specialized baffles, air plenums, and fan configurations that optimize air velocity and distribution across the heat exchanger.

Additionally, the incorporation of advanced materials and coatings can contribute to improved ACHE performance. For instance, the use of hydrophilic or superhydrophobic coatings can help mitigate the effects of fouling, reducing the need for frequent maintenance and enhancing the system’s long-term efficiency.

Maintaining and Optimizing Air-Cooled Heat Exchanger Performance

Proper maintenance and ongoing optimization are essential to ensure the continued efficiency and reliability of air-cooled heat exchangers. Regular cleaning and inspection procedures are crucial to address issues such as:

-

Fouling: Accumulation of dirt, debris, or scale on the heat exchanger surfaces can impede heat transfer, reducing overall efficiency. Implementing a proactive cleaning regimen, including chemical or mechanical cleaning, can help mitigate this problem.

-

Corrosion: Exposure to harsh chemicals, high temperatures, or aggressive environments can lead to corrosion of ACHE components, compromising their structural integrity and performance. Regularly inspecting for signs of corrosion and applying protective coatings or selecting more corrosion-resistant materials can help extend the system’s lifespan.

-

Air Flow Optimization: Ensuring optimal air flow through the heat exchanger is essential for maximizing heat transfer. Monitoring and adjusting fan speeds, as well as addressing any obstructions or changes in air flow patterns, can help optimize the system’s thermal performance.

-

Leak Detection: Identifying and addressing any leaks in the ACHE system is critical, as even minor leaks can compromise the heat transfer process and lead to wider system issues.

By implementing a comprehensive maintenance program and leveraging advanced monitoring technologies, operators can proactively identify and address performance-related concerns, ensuring the long-term efficiency and reliability of their air-cooled heat exchangers.

Addressing Emerging Trends and Challenges in Air-Cooled Heat Exchanger Applications

As industries continue to prioritize energy efficiency, sustainability, and cost-effectiveness, the demand for innovative air-cooled heat exchanger solutions is on the rise. Several emerging trends and challenges are shaping the future of this critical thermal management technology:

Adapting to Water-Scarce Environments

In regions with limited water availability, ACHEs offer a sustainable alternative to traditional water-cooled systems, eliminating the need for water consumption in the cooling process. This makes them increasingly attractive for industrial applications in water-stressed areas, particularly in the oil and gas, petrochemical, and power generation sectors.

Meeting Stringent Emission and Efficiency Regulations

Governments worldwide are implementing stricter regulations on energy efficiency and emissions, driving industries to adopt more sustainable technologies. Air-cooled heat exchangers, with their ability to reduce water usage and greenhouse gas emissions, are well-positioned to help companies meet these regulatory requirements.

Tackling Noise Pollution Concerns

One of the key challenges associated with air-cooled heat exchangers is the noise generated by the fans used to draw or push air through the system. This can be a significant concern, especially in populated areas or sensitive environments. Addressing noise pollution through innovative fan designs, acoustic enclosures, and strategic placement of ACHEs is crucial for broader market acceptance.

Enhancing Reliability and Resilience

As air-cooled heat exchangers become increasingly critical to industrial operations, their reliability and resilience are paramount. Advancing materials, fabrication techniques, and predictive maintenance strategies can help ensure ACHE systems continue to perform reliably, even under demanding operating conditions.

Optimizing for Compact and Modular Designs

The growing demand for space-efficient and versatile thermal management solutions is driving the need for more compact and modular air-cooled heat exchanger designs. These innovative configurations can be easily integrated into existing facilities or deployed in space-constrained environments, such as data centers and industrial plants.

Leveraging Digital Technologies for Improved Performance

The integration of digital technologies, such as real-time monitoring, predictive analytics, and IoT-enabled sensors, can significantly enhance the performance and maintenance of air-cooled heat exchangers. These advancements allow for proactive fault detection, optimization of operating parameters, and predictive maintenance, enabling operators to maximize the efficiency and uptime of their ACHE systems.

By addressing these emerging trends and challenges, manufacturers and end-users can unlock the full potential of air-cooled heat exchangers, driving greater energy efficiency, cost savings, and environmental sustainability across various industries.

Exploring Air-Cooled Heat Exchanger Applications in the Petrochemical and Oil and Gas Sectors

The petrochemical and oil and gas industries are prime examples of sectors that heavily rely on the efficiency and versatility of air-cooled heat exchangers. These systems play a critical role in various processes, from crude oil refining to natural gas processing and power generation.

Refining and Petrochemical Applications

In the refining and petrochemical industry, air-cooled heat exchangers are used for a wide range of applications, including:

- Crude Oil Cooling: ACHEs are employed to cool down crude oil after distillation, enabling efficient storage and downstream processing.

- Hydrocarbon Cooling: These heat exchangers play a vital role in cooling various hydrocarbon streams, such as naphtha, gasoline, and diesel, during the refining process.

- Process Fluid Cooling: ACHEs are used to cool process fluids, including water and various chemical solutions, ensuring optimal operating temperatures for various petrochemical processes.

- Vent Gas Cooling: Air-cooled heat exchangers are utilized to cool vent gases, often containing volatile organic compounds (VOCs), before they are released into the atmosphere or further processed.

The petrochemical industry’s focus on energy efficiency, water conservation, and environmental compliance makes air-cooled heat exchangers an attractive choice, as they offer a sustainable and reliable cooling solution without the need for water consumption.

Oil and Gas Applications

In the oil and gas sector, air-cooled heat exchangers are employed in a variety of applications, including:

- Natural Gas Processing: ACHEs are used to cool natural gas streams, removing impurities and preparing the gas for further processing or distribution.

- Compressor Cooling: These heat exchangers are essential for cooling the air or gas compressed by various types of compressors, ensuring efficient operation and equipment protection.

- Lubricant Cooling: Air-cooled heat exchangers help maintain the optimal temperature of lubricating oils used in rotating equipment, such as turbines and compressors, preventing premature wear and failure.

- Waste Heat Recovery: ACHEs can be integrated into waste heat recovery systems, capturing and repurposing the thermal energy generated by various oil and gas processes, thereby improving overall energy efficiency.

The rugged design and corrosion resistance of air-cooled heat exchangers make them well-suited for the harsh environments encountered in the oil and gas industry, where they must withstand exposure to high temperatures, aggressive chemicals, and potential fouling from contaminants.

Enhancing Performance and Reliability in Petrochemical and Oil and Gas Applications

To ensure the optimal performance and reliability of air-cooled heat exchangers in the petrochemical and oil and gas sectors, several key strategies can be employed:

- Material Selection: Choosing materials like stainless steel or high-performance alloys that can withstand the specific operating conditions and environmental factors is crucial for prolonging the ACHE’s lifespan and minimizing maintenance requirements.

- Fin Design Optimization: Leveraging advanced fin designs, such as extruded or louvered fins, can enhance heat transfer efficiency and reduce the impact of fouling, improving overall system performance.

- Air Flow Management: Carefully designing the air flow path, incorporating features like baffles and air plenums, can optimize air velocity and distribution, leading to increased heat transfer rates.

- Predictive Maintenance: Implementing predictive maintenance strategies, such as vibration monitoring, thermographic analysis, and performance trend tracking, can help identify potential issues before they escalate, enabling proactive maintenance and minimizing unplanned downtime.

- Integrated Monitoring and Controls: Integrating advanced monitoring and control systems, including IoT-enabled sensors and data analytics, can provide real-time insights into ACHE performance, allowing for dynamic optimization and improved reliability.

By adopting these strategies, petrochemical and oil and gas companies can ensure the long-term efficiency, reliability, and sustainability of their air-cooled heat exchanger systems, contributing to the overall optimization of their thermal management processes.

Conclusion: The Future of Air-Cooled Heat Exchangers in Industrial Thermal Management

As the global demand for efficient, sustainable, and cost-effective thermal management solutions continues to grow, the air-cooled heat exchanger market is poised for significant expansion, particularly in the petrochemical and oil and gas industries. Driven by factors such as increasing industrialization, stricter environmental regulations, and the need for water conservation, the air-cooled heat exchanger market is projected to reach USD 5.69 billion by 2029, growing at a CAGR of 7.5% from 2024 to 2029.

To capitalize on this growth, manufacturers and end-users must stay attuned to the latest advancements in ACHE design, materials, and performance optimization techniques. By leveraging innovative fin designs, optimizing air flow management, and integrating predictive maintenance strategies, industry stakeholders can enhance the efficiency, reliability, and sustainability of their air-cooled heat exchanger systems, ultimately driving greater operational and environmental benefits.

As the world continues to shift towards more sustainable practices, the role of air-cooled heat exchangers in the petrochemical and oil and gas sectors will become increasingly crucial. By embracing these cutting-edge thermal management solutions, companies can not only improve their bottom line but also contribute to a greener, more efficient future. Visit https://www.aircooledheatexchangers.net/ to explore the latest trends and innovations in the world of air-cooled heat exchangers.