Optimizing Air-Cooled Heat Exchanger Performance through Material Innovation

As the demand for efficient and sustainable thermal management solutions continues to grow across industries, the role of air-cooled heat exchangers has become increasingly crucial. These versatile heat transfer devices are widely employed in applications ranging from HVAC systems and industrial processes to power generation and transportation. Achieving optimal performance, durability, and reliability in air-cooled heat exchangers requires a deep understanding of the complex interplay between materials, manufacturing methods, and operational conditions.

One of the key factors in enhancing air-cooled heat exchanger longevity and efficacy is the selection of advanced materials that can withstand the rigors of high-temperature, corrosive, and abrasive environments. Mersen, a global leader in industrial solutions, has developed a range of specialized materials and coatings tailored to address the unique challenges faced by air-cooled heat exchangers.

Graphite: A Thermal Powerhouse

At the forefront of Mersen’s material innovation is high-purity graphite, a versatile material that excels in the demanding conditions encountered in air-cooled heat exchanger applications. Graphite’s exceptional thermal conductivity, resistance to oxidation, and chemical inertness make it an ideal choice for components that must operate in extreme environments.

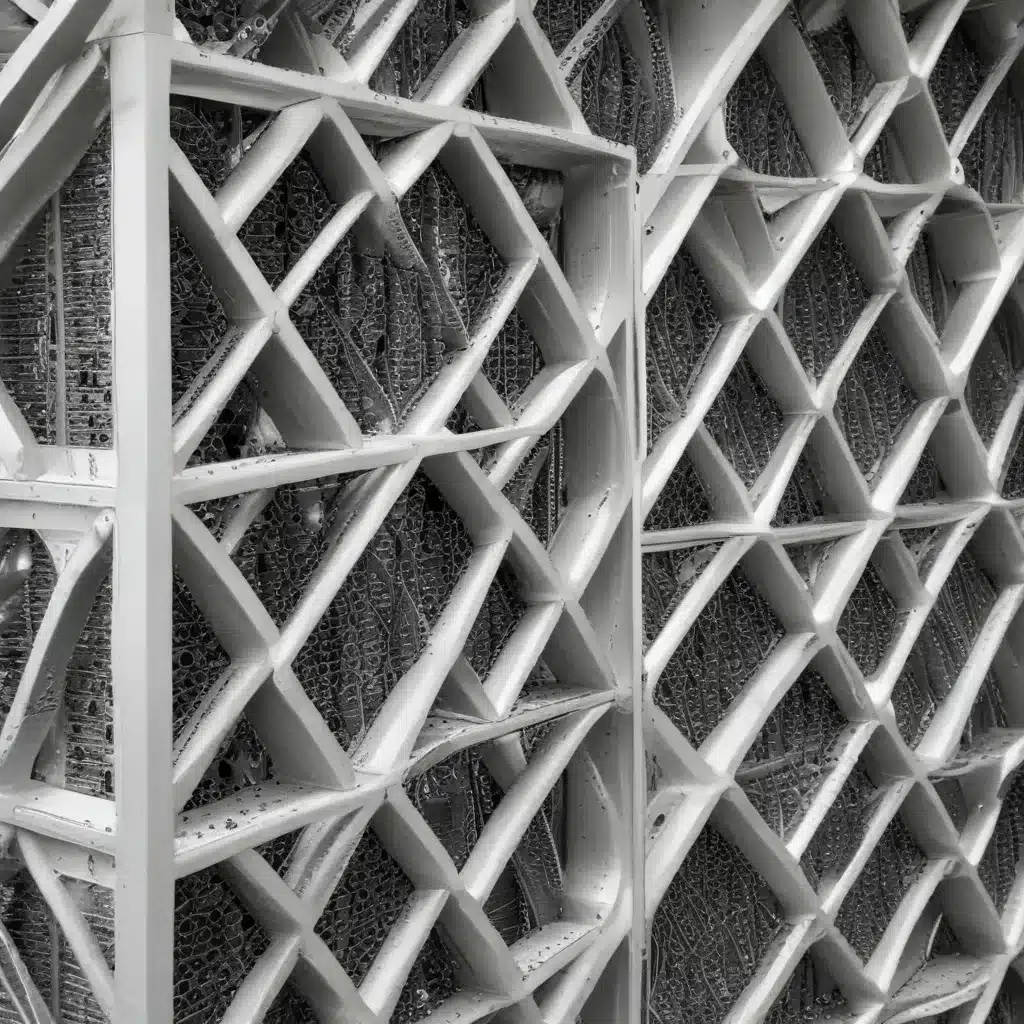

In air-cooled heat exchangers, graphite is commonly utilized in crucial components such as heat exchanger tubes, fin materials, and support structures. The high thermal conductivity of graphite ensures efficient heat transfer, while its corrosion resistance and structural integrity help maintain the heat exchanger’s performance over an extended lifetime.

Mersen’s advanced purification techniques further enhance the purity and quality of graphite used in air-cooled heat exchangers, minimizing the risk of contamination and ensuring consistent thermal performance. This commitment to material excellence is a cornerstone of Mersen’s approach to enhancing the durability and reliability of air-cooled heat exchangers.

Protective Coatings: Shielding Against Wear and Corrosion

While graphite’s inherent properties make it a compelling choice for air-cooled heat exchanger components, the material’s susceptibility to oxidation at high temperatures can present challenges. Mersen has developed innovative coating solutions to address this issue and further extend the lifespan of air-cooled heat exchangers.

By applying Silicon Carbide (SiC) and Tantalum Carbide (TaC) coatings to graphite parts, Mersen ensures enhanced durability and resistance to harsh operating environments. These protective coatings act as a barrier, shielding the underlying graphite from erosion, corrosion, and oxidation, thereby preserving the heat exchanger’s structural integrity and thermal performance over time.

The use of SiC and TaC coatings not only enhances the lifespan of air-cooled heat exchangers but also enables the use of graphite in applications where its inherent vulnerabilities would have previously posed limitations. This innovative approach to material engineering expands the range of conditions in which air-cooled heat exchangers can operate reliably, meeting the ever-evolving demands of modern industrial processes.

Advancing Air-Cooled Heat Exchanger Manufacturing Processes

Alongside the development of cutting-edge materials, Mersen has also made significant strides in enhancing the manufacturing processes used to fabricate air-cooled heat exchangers. By leveraging its expertise in precision engineering and process optimization, the company is able to deliver air-cooled heat exchangers that consistently meet the stringent requirements of diverse industries.

Precision Machining and Assembly

Ensuring the precise dimensional accuracy and geometric integrity of air-cooled heat exchanger components is essential for maintaining optimal performance and reliability. Mersen’s advanced machining capabilities, including computer numerical control (CNC) technology, enable the manufacture of intricate parts with tight tolerances, minimizing the risk of misalignment or uneven heat distribution.

The company’s commitment to precision extends beyond individual components to the overall assembly process. Mersen’s skilled technicians employ meticulous assembly techniques, leveraging specialized tools and jigs to ensure a seamless integration of all heat exchanger elements. This attention to detail helps to maintain the structural stability and thermal efficiency of the final air-cooled heat exchanger unit, even under demanding operating conditions.

Advanced Welding and Joining Techniques

The durability and structural integrity of air-cooled heat exchangers are heavily influenced by the quality of the welding and joining processes used in their fabrication. Mersen has invested in state-of-the-art welding technologies and highly trained personnel to deliver exceptional results.

From specialized welding techniques for dissimilar materials to advanced joining methods for complex geometries, Mersen’s manufacturing expertise ensures the creation of air-cooled heat exchangers that can withstand the rigors of industrial applications. The company’s commitment to quality control and stringent inspection protocols further guarantees the reliability and long-term performance of these critical thermal management components.

Innovative Testing and Quality Assurance

Mersen’s dedication to delivering air-cooled heat exchangers of the highest caliber extends to its comprehensive testing and quality assurance protocols. By employing advanced simulation software, experimental validation, and rigorous quality control measures, the company ensures that each air-cooled heat exchanger meets or exceeds industry standards for efficiency, durability, and safety.

From structural integrity tests to thermal performance evaluations, Mersen’s multifaceted approach to quality assurance provides customers with the confidence that their air-cooled heat exchangers will perform reliably and consistently, even in the most demanding operating environments.

Enhancing Energy Efficiency and Sustainability

As the global focus on sustainability and environmental responsibility intensifies, air-cooled heat exchangers have emerged as a critical component in the drive for more energy-efficient thermal management solutions. Mersen’s commitment to innovation encompasses not only material advancements and manufacturing excellence but also a steadfast dedication to improving the energy efficiency and environmental impact of air-cooled heat exchangers.

Optimizing Heat Transfer Efficiency

Through its deep understanding of heat transfer principles and extensive experience in the field, Mersen has developed air-cooled heat exchanger designs that maximize the efficiency of heat transfer, minimizing energy consumption and environmental impact. By optimizing factors such as airflow, fin geometry, and material selection, Mersen’s air-cooled heat exchangers are engineered to achieve superior thermal performance, delivering tangible energy savings for its customers.

Reducing Environmental Footprint

The transition towards more sustainable practices is a key focus for Mersen, and this commitment is reflected in the design and manufacturing of its air-cooled heat exchangers. The company’s emphasis on using high-purity, recyclable materials, such as graphite, helps to minimize the environmental impact of these critical thermal management components.

Additionally, Mersen’s air-cooled heat exchangers are designed to operate with reduced water consumption, making them a viable alternative to traditional water-cooled systems in regions where water scarcity is a concern. This approach not only contributes to the preservation of natural resources but also aligns with the growing demand for more environmentally conscious industrial solutions.

Conclusion: The Future of Air-Cooled Heat Exchangers

As industries navigate the ever-evolving landscape of technological advancements and sustainability requirements, the role of air-cooled heat exchangers has become increasingly pivotal. Mersen’s unwavering commitment to material innovation, manufacturing excellence, and environmental stewardship positions the company as a leader in the development of next-generation air-cooled heat exchangers.

By leveraging cutting-edge materials like high-purity graphite and advanced coating technologies, Mersen is redefining the boundaries of air-cooled heat exchanger durability and reliability. Coupled with its precision engineering and quality assurance processes, the company’s solutions are poised to meet the growing demand for efficient, long-lasting, and sustainable thermal management systems across diverse sectors.

As the world continues to seek more eco-friendly and energy-efficient technologies, the future of air-cooled heat exchangers looks brighter than ever. With Mersen’s innovative approach and unwavering commitment to excellence, the air-cooled heat exchanger industry is set to witness a transformation that will further propel the pursuit of a more sustainable, resilient, and technologically advanced industrial landscape.

To learn more about Mersen’s cutting-edge air-cooled heat exchanger solutions, visit https://www.aircooledheatexchangers.net/.