Understanding Phase-Change Materials

Phase-change materials (PCMs) are substances that can store and release large amounts of thermal energy during their phase transition from solid to liquid or liquid to gas. This unique property makes them highly valuable for thermal energy storage applications, particularly in solar energy systems, building heating and cooling, and various industrial processes.

The electrochemical behavior of PCMs plays a crucial role in their performance and efficiency within thermal energy storage systems. By understanding the underlying electrochemical principles, researchers and engineers can optimize the design, integration, and operation of PCM-based technologies to enhance their effectiveness and sustainability.

Electrochemical Properties of PCMs

The electrochemical properties of PCMs are influenced by several factors, including their molecular structure, chemical composition, and the presence of additives or nanoparticles. These properties govern the materials’ ability to undergo reversible phase transitions, store thermal energy, and transfer heat efficiently.

Thermal Conductivity: One of the critical electrochemical properties of PCMs is their thermal conductivity. The ability of a PCM to conduct heat is crucial for its performance in thermal energy storage applications. Higher thermal conductivity allows for faster heat transfer during the charging and discharging cycles, improving the overall system efficiency.

Melting and Solidification Behavior: The melting and solidification temperatures of PCMs directly impact their suitability for specific temperature ranges and applications. The phase-change process involves complex electrochemical reactions and interactions that can be influenced by factors such as supercooling, nucleation, and crystal growth.

Latent Heat of Fusion: The latent heat of fusion, or the amount of energy released or absorbed during the phase transition, is a fundamental property of PCMs. A higher latent heat of fusion enables the material to store more thermal energy per unit mass, making it more effective for thermal energy storage applications.

Reversibility and Cycling Stability: The ability of PCMs to undergo repeated phase transitions without significant degradation or loss of performance is crucial for their long-term reliability in thermal energy storage systems. The electrochemical stability of the materials, as well as their compatibility with other system components, determines their cycling stability.

Enhancing PCM Performance

Researchers have explored various strategies to enhance the electrochemical properties and performance of PCMs for thermal energy storage applications. These approaches include:

-

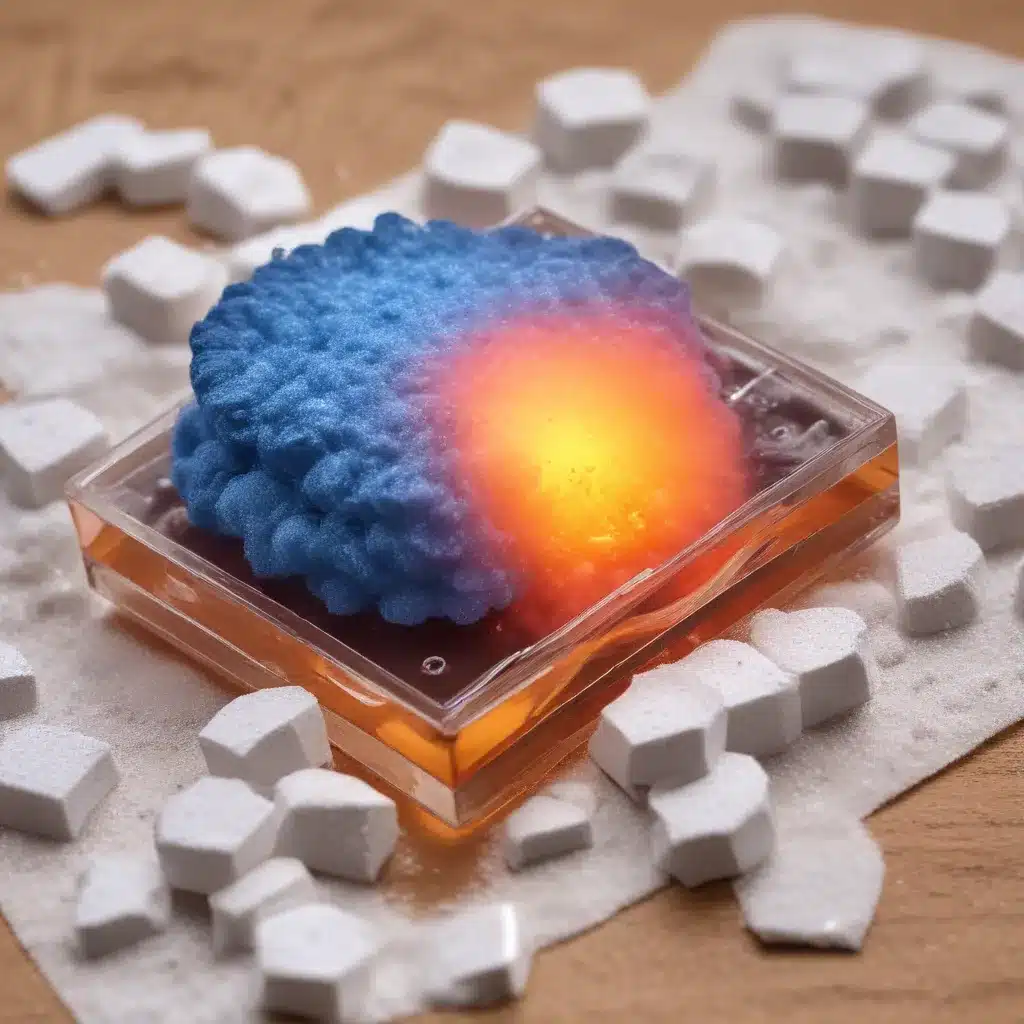

Microencapsulation: Encapsulating PCMs in microscale or nanoscale shells can improve their thermal conductivity, prevent leakage, and enhance their stability during cycling.

-

Nanoparticle Additives: Incorporating nanoparticles, such as carbon-based materials or metal oxides, into PCMs can improve thermal conductivity, nucleation, and phase-change behavior.

-

Composite PCMs: Combining PCMs with high-thermal-conductivity materials, such as graphene, carbon nanotubes, or metal foams, can significantly enhance heat transfer and storage capacity.

-

Electrochemical Modifications: Exploring electrochemical techniques, such as surface functionalization or electrochemical deposition, to tailor the properties of PCMs and improve their performance in thermal energy storage applications.

-

Phase-Change Slurries and Emulsions: Developing phase-change slurries or emulsions by dispersing PCM microcapsules or nanoparticles in a base fluid can enhance heat transfer and enable novel heat storage and transport mechanisms.

By understanding the electrochemical principles governing PCMs and leveraging these performance-enhancing strategies, researchers and engineers can design more efficient and reliable thermal energy storage systems for a wide range of applications, including renewable energy integration, building energy management, and industrial process optimization.

Thermal Energy Storage Applications of PCMs

The unique electrochemical properties of phase-change materials make them highly versatile for a variety of thermal energy storage applications. Let’s explore some of the key areas where PCMs are being utilized:

Solar Thermal Energy Storage

One of the primary applications of PCMs is in solar thermal energy storage systems. During periods of high solar irradiance, PCMs can absorb and store the excess thermal energy, which can then be released during periods of low or no solar radiation to provide continuous heating or cooling. This helps to overcome the intermittent nature of solar energy and improves the overall efficiency of solar thermal systems.

Researchers have explored various PCM-based solar thermal storage solutions, such as integrating PCMs into solar collectors, developing PCM-enhanced thermal energy storage tanks, and utilizing PCM-based heat exchangers to improve the performance of solar-powered heating and cooling systems.

Building Energy Management

PCMs can play a crucial role in improving the energy efficiency of buildings by regulating indoor temperature and reducing the demand for heating and cooling. During periods of high heat load, PCMs can absorb the excess thermal energy, preventing the indoor temperature from rising rapidly. Conversely, during periods of low heat load, the stored thermal energy can be released, maintaining a comfortable indoor environment.

Research has shown that incorporating PCMs into building materials, such as walls, floors, or ceilings, can significantly reduce energy consumption for heating and cooling, leading to more sustainable and energy-efficient buildings.

Industrial Process Optimization

PCMs can also be utilized in various industrial processes to optimize thermal management and energy efficiency. For example, in the food processing industry, PCMs can be used to maintain the temperature of refrigerated storage units or to regulate the temperature during critical processes, such as pasteurization or drying.

In the manufacturing sector, PCMs can be integrated into production equipment or tool cooling systems to absorb and release thermal energy, reducing the burden on traditional cooling systems and improving overall process efficiency.

Thermal Management of Energy Storage Systems

The electrochemical properties of PCMs make them valuable for thermal management in energy storage systems, such as batteries and fuel cells. By incorporating PCMs into these systems, the temperature fluctuations can be effectively dampened, improving the performance, safety, and lifespan of the energy storage devices.

Research has demonstrated the use of PCMs in battery thermal management systems, where the PCMs can absorb excess heat generated during charging or discharging, preventing the battery from overheating and ensuring optimal operating conditions.

Challenges and Future Trends

While phase-change materials have shown great promise in various thermal energy storage applications, there are still some challenges that need to be addressed to further improve their performance and widespread adoption.

Improving Thermal Conductivity

One of the main challenges with PCMs is their inherently low thermal conductivity, which can limit the rate of heat transfer during the charging and discharging cycles. Researchers are exploring various approaches, such as the use of nanoparticle additives, composite PCMs, and microencapsulation techniques, to enhance the thermal conductivity of these materials.

Overcoming Supercooling and Phase Segregation

Supercooling, where the PCM remains in the liquid state even below its melting point, and phase segregation, where the components of a PCM separate during repeated cycling, can affect the reliability and performance of thermal energy storage systems. Addressing these issues through chemical modifications, nucleating agents, or encapsulation methods is an active area of research.

Developing Cost-Effective and Scalable Manufacturing

The large-scale production and widespread adoption of PCM-based thermal energy storage systems depend on the development of cost-effective and scalable manufacturing processes. Researchers and engineers are exploring innovative manufacturing techniques, such as 3D printing and continuous production methods, to make PCM-based solutions more accessible and economically viable.

Improving Cycling Stability and Lifetime

Ensuring the long-term reliability and durability of PCM-based thermal energy storage systems is crucial for their widespread adoption. Enhancing the cycling stability and lifetime of PCMs through material modifications, coatings, or system design optimizations is an important area of focus.

Integrating PCMs with Other Energy Technologies

The synergistic integration of PCMs with other energy technologies, such as solar photovoltaics, heat pumps, or waste heat recovery systems, can further enhance the overall efficiency and performance of thermal energy storage applications. Developing these integrated systems and optimizing their design and operation is a promising research direction.

As the demand for sustainable and efficient thermal energy storage solutions continues to grow, the research and development of phase-change materials with improved electrochemical properties will remain a crucial focus area. By addressing these challenges and exploring new frontiers, the future of PCM-based thermal energy storage systems holds great promise for a more sustainable and energy-efficient future.

Conclusion

Phase-change materials have emerged as a promising solution for thermal energy storage, offering significant advantages in applications such as solar thermal energy, building energy management, and industrial process optimization. The understanding of the underlying electrochemical properties of PCMs, including their thermal conductivity, phase-change behavior, and reversibility, is crucial for the design and optimization of these materials and their integration into thermal energy storage systems.

Through strategies like microencapsulation, nanoparticle additives, and composite PCMs, researchers are continuously working to enhance the performance and overcome the challenges associated with PCMs. As the demand for sustainable and efficient thermal energy storage solutions grows, the future holds exciting advancements in the electrochemistry of phase-change materials, paving the way for more widespread adoption and a more energy-efficient future.

To stay up-to-date with the latest developments in air-cooled heat exchangers and thermal energy storage technologies, be sure to visit the Air Cooled Heat Exchangers blog regularly.