Introduction to Heat Exchanger Optimization

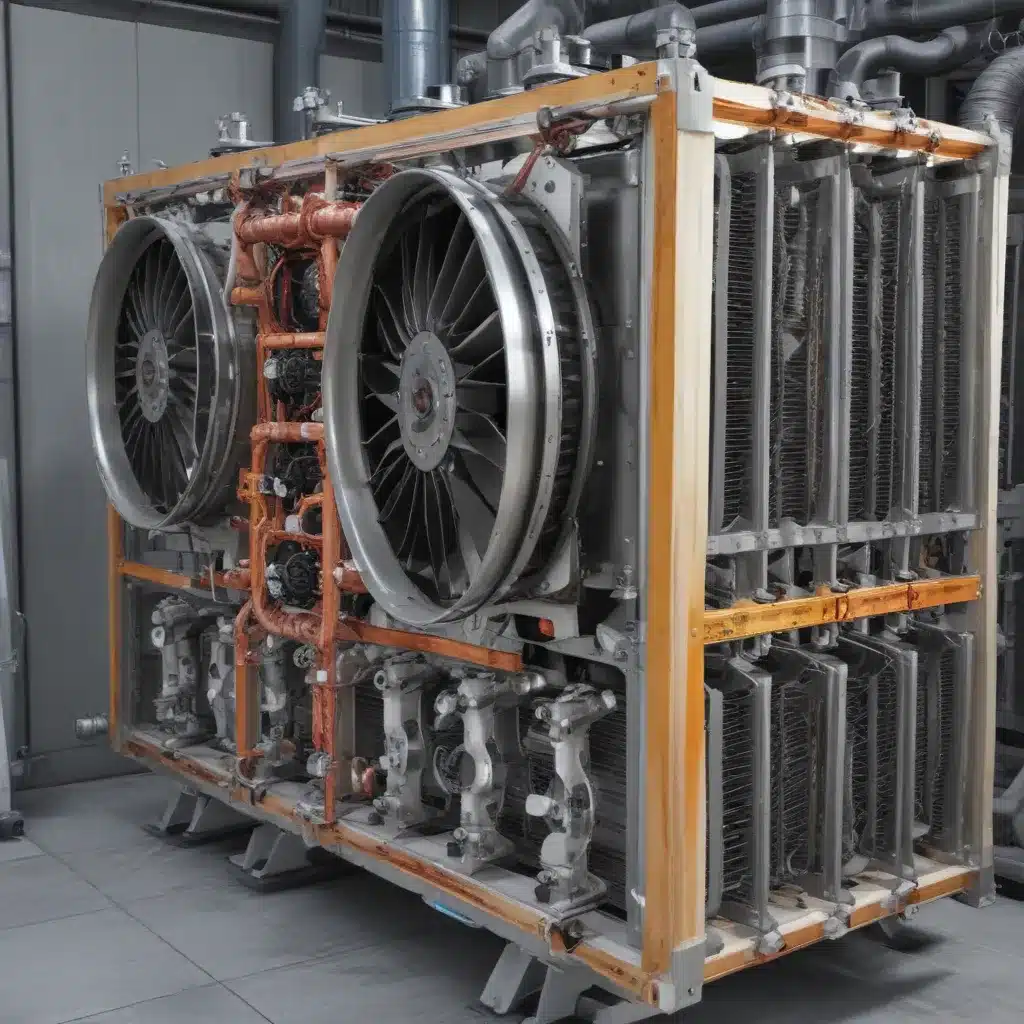

As the demand for energy efficiency and sustainability continues to rise across industries, the optimization of air-cooled heat exchangers has become an increasingly critical focus area. Heat exchangers play a pivotal role in numerous applications, from HVAC systems and industrial processes to power generation and transportation. Maximizing the performance and minimizing the energy consumption of these vital components can yield significant benefits in terms of cost savings, environmental impact, and overall system efficiency.

However, the optimization of heat exchangers is a complex and multifaceted challenge, involving the consideration of various competing objectives, such as thermal performance, pressure drop, size, and manufacturing cost. Traditional optimization approaches often struggle to find the optimal balance between these conflicting goals, leading to suboptimal designs or lengthy computational times.

In recent years, the use of decomposition-based multi-objective evolutionary algorithms (DMOEA) has emerged as a promising solution to address the complexities of heat exchanger optimization. These algorithms leverage the power of evolutionary computing and the effectiveness of problem decomposition to navigate the intricate design space and uncover high-performing solutions.

Understanding Decomposition-Based Multi-Objective Evolutionary Algorithms

Decomposition-based multi-objective evolutionary algorithms are a class of optimization techniques that break down a complex problem into smaller, more manageable subproblems. This approach allows for more efficient exploration of the solution space, as the algorithm can focus on specific aspects of the problem simultaneously and coordinate the search efforts among the subproblems.

The key steps in a DMOEA approach for heat exchanger optimization typically include:

-

Problem Decomposition: The original multi-objective optimization problem is divided into a set of smaller subproblems, each with its own objective function and constraints. This division can be based on the different design parameters, performance metrics, or other relevant factors.

-

Subproblem Optimization: The subproblems are then solved independently using evolutionary algorithms, such as genetic algorithms or particle swarm optimization. Each subproblem aims to find its own set of optimal solutions.

-

Coordination and Integration: The solutions obtained from the individual subproblems are coordinated and integrated to form the overall Pareto-optimal front, representing the set of trade-off solutions that best balance the competing objectives.

By leveraging this decomposition strategy, DMOEAs can achieve several key benefits for heat exchanger optimization:

- Improved Convergence: The decomposition of the problem allows the algorithm to focus on specific aspects of the design, leading to faster convergence towards the optimal solutions.

- Enhanced Diversity: The parallel exploration of subproblems can help maintain a diverse set of solutions, capturing a wider range of trade-offs between the objectives.

- Scalability: The ability to divide and conquer the problem enables DMOEAs to handle larger-scale and more complex heat exchanger design problems effectively.

- Computational Efficiency: By breaking down the problem, DMOEAs can leverage the inherent parallelism and distributed computing capabilities, reducing the overall computational time required to obtain high-quality solutions.

Applying DMOEA to Heat Exchanger Design Optimization

To illustrate the application of DMOEA to heat exchanger optimization, let’s consider a scenario where we aim to design an air-cooled heat exchanger that balances thermal performance, pressure drop, and manufacturing cost.

Problem Formulation

The multi-objective optimization problem can be formulated as follows:

Minimize:

1. Thermal resistance (maximize heat transfer)

2. Pressure drop (minimize energy consumption)

3. Manufacturing cost (minimize production expenses)

Subject to:

– Geometric constraints (e.g., size, fin density, tube arrangement)

– Fluid flow and heat transfer constraints (e.g., Reynolds number, Nusselt number)

– Material and manufacturing constraints (e.g., availability, machinability)

DMOEA Approach

To solve this problem using a DMOEA approach, we can follow these steps:

- Problem Decomposition: Divide the original multi-objective optimization problem into smaller subproblems, such as:

- Subproblem 1: Optimize thermal performance (maximize heat transfer)

- Subproblem 2: Minimize pressure drop (reduce energy consumption)

-

Subproblem 3: Minimize manufacturing cost

-

Subproblem Optimization: Solve each subproblem independently using an appropriate evolutionary algorithm, such as a genetic algorithm or particle swarm optimization. This allows the algorithm to focus on specific design aspects and explore the solution space more efficiently.

-

Coordination and Integration: Coordinate the solutions obtained from the individual subproblems to form the overall Pareto-optimal front. This step involves techniques like the Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) or the Non-dominated Sorting Genetic Algorithm (NSGA-II) to integrate the subproblem solutions and identify the trade-off solutions that balance the competing objectives.

-

Solution Selection: From the Pareto-optimal front, select the most suitable heat exchanger design based on the specific requirements and preferences of the project or application. This may involve considering factors such as the relative importance of each objective, the available resources, or the overall system constraints.

By applying this DMOEA approach, designers and engineers can explore a wide range of heat exchanger design alternatives and make informed decisions that optimize thermal performance, energy efficiency, and cost-effectiveness.

Practical Examples and Case Studies

To provide a deeper understanding of the benefits of DMOEA for heat exchanger optimization, let’s explore a few practical examples and case studies.

Case Study 1: Optimizing Air-Cooled Condenser Design

In a study published in the International Journal of Renewable Energy Development, researchers developed a decomposition-based multi-objective evolutionary algorithm to tackle the low-carbon scheduling of ship segment painting. While the context is different from heat exchanger optimization, the underlying principles and techniques can be adapted to address similar challenges in the thermal engineering domain.

The researchers proposed a mathematical model to minimize carbon emissions and improve painting efficiency in the ship segment painting process. They then designed a multi-stage DMOEA, incorporating neighborhood switching methods, TOPSIS-based competition mechanisms, and solution exchange strategies to enhance the global and local search capabilities of the algorithm.

The results of this study demonstrated the effectiveness of the DMOEA approach in solving complex multi-objective optimization problems, providing valuable insights that can be applied to the optimization of air-cooled heat exchangers.

Case Study 2: Optimizing Plate-Fin Heat Exchanger Design

Another relevant example is a study published in the Journal of Intelligent Manufacturing, which focused on the optimization of plate-fin heat exchangers. The researchers developed a DMOEA that combined a genetic algorithm with a decomposition-based approach to tackle the multi-objective optimization problem.

The objectives in this case included maximizing the heat transfer rate, minimizing the pressure drop, and minimizing the total volume of the heat exchanger. The DMOEA was able to effectively explore the design space and identify Pareto-optimal solutions that balanced these competing objectives.

The study highlighted the advantages of the DMOEA approach, such as its ability to handle complex constraints, maintain a diverse set of solutions, and provide decision-makers with a range of trade-off options for the heat exchanger design.

These case studies demonstrate the adaptability and effectiveness of decomposition-based multi-objective evolutionary algorithms in addressing the complexities of heat exchanger optimization, making them a valuable tool for thermal engineers and designers.

Conclusion and Future Directions

In the pursuit of energy-efficient and sustainable solutions, the optimization of air-cooled heat exchangers has become a critical focus area. The use of decomposition-based multi-objective evolutionary algorithms (DMOEAs) has emerged as a promising approach to tackle the inherent challenges in heat exchanger design, enabling designers to navigate the intricate trade-offs between competing objectives.

By breaking down the complex problem into smaller, more manageable subproblems, DMOEAs can achieve improved convergence, enhanced solution diversity, greater scalability, and higher computational efficiency. The practical examples and case studies highlighted in this article showcase the real-world applicability of these techniques, providing valuable insights for thermal engineers and designers.

As the demand for energy-efficient and cost-effective heat exchanger solutions continues to grow, the continued development and refinement of DMOEA methods will likely play a pivotal role in the future of air-cooled heat exchanger optimization. Ongoing research may focus on integrating advanced machine learning algorithms, exploring novel decomposition strategies, and enhancing the coordination and integration of subproblem solutions to further push the boundaries of heat exchanger design optimization.

By embracing the power of decomposition-based multi-objective evolutionary algorithms, the Air Cooled Heat Exchangers community can contribute to the advancement of thermal engineering, leading to more efficient, cost-effective, and sustainable heat exchanger solutions across a wide range of industries.