Optimizing the Performance and Environmental Footprint of Air-Cooled Heat Exchangers

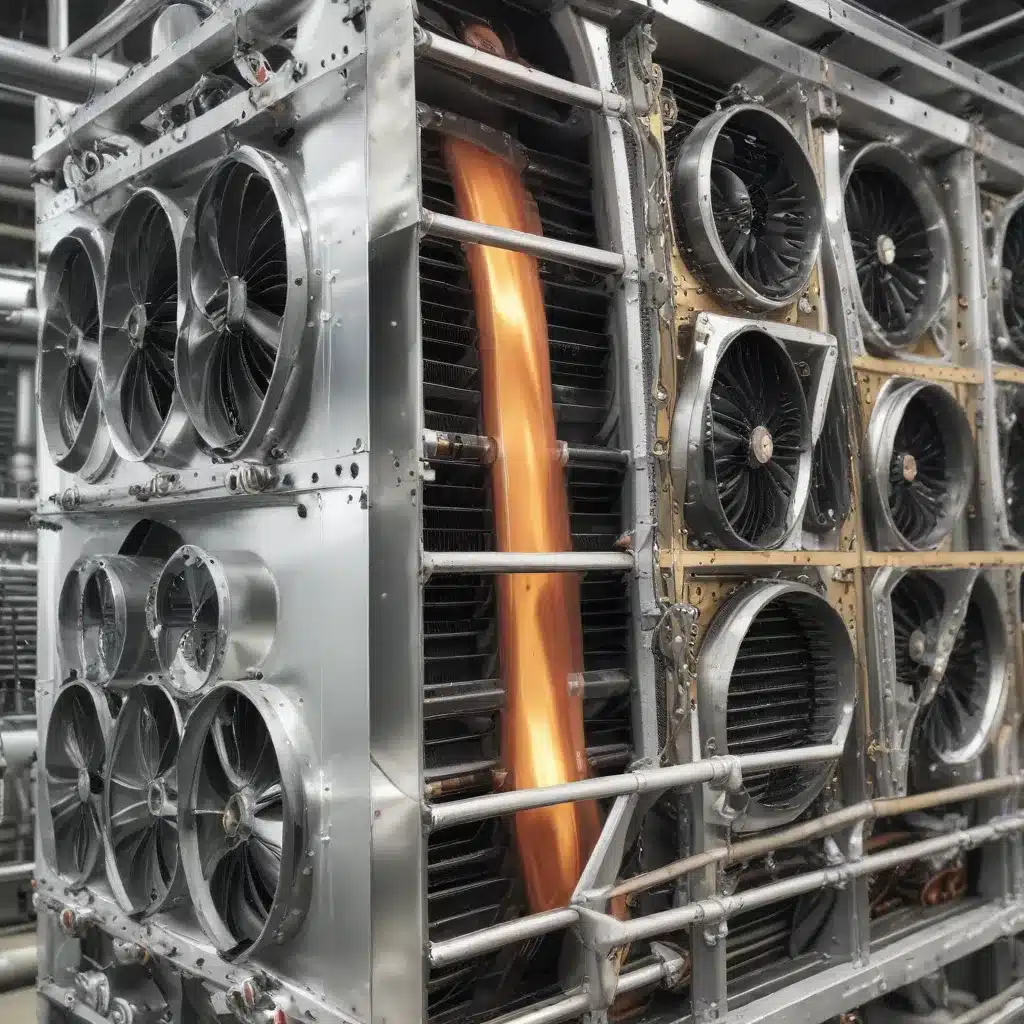

Air-cooled heat exchangers play a pivotal role in diverse industrial processes, from power generation and petrochemical refining to HVAC systems and food processing. As the demand for efficient and sustainable thermal management solutions continues to grow, the need to unlock the full potential of air-cooled heat exchangers has become increasingly crucial.

In this comprehensive guide, we will explore cutting-edge techniques and innovations that can significantly improve the efficiency, durability, and environmental sustainability of air-cooled heat exchangers across a wide range of industrial applications. By delving into the latest advancements in materials, design, and maintenance strategies, we aim to empower industry professionals with the knowledge and tools to enhance the performance and eco-friendliness of their air-cooled heat exchanger systems.

Enhancing Thermal Efficiency through Advanced Materials and Design

One of the primary drivers for improving air-cooled heat exchanger performance is the pursuit of higher thermal efficiency. This can be achieved through the strategic selection of advanced materials and the optimization of heat exchanger design.

High-Performance Heat Transfer Surfaces

Leveraging the latest advancements in surface engineering, heat exchanger manufacturers are developing innovative fin and tube geometries that promote enhanced heat transfer. These include:

- Herringbone Fin Designs: Featuring a unique wave-like pattern, herringbone fins create turbulent airflow, improving convective heat transfer and increasing the overall heat transfer coefficient.

- Louvered Fin Designs: Louvered fins, with their intricate patterns of small, angled louvers, disrupt the boundary layer and induce more effective air-side heat transfer.

- Micro-Channel Fin Designs: Micro-channel fins, with their densely packed, narrow passages, significantly increase the surface area-to-volume ratio, leading to enhanced heat transfer performance.

Complementing these advanced fin geometries, the use of highly conductive materials, such as copper and aluminum alloys, further enhances the heat transfer capabilities of air-cooled heat exchangers. Additionally, the strategic application of coatings and surface treatments can improve wettability, reduce fouling, and optimize heat transfer, contributing to overall efficiency improvements.

Optimized Airflow and Fluid Dynamics

The design of the air-cooled heat exchanger’s housing and air-flow paths plays a crucial role in maximizing thermal efficiency. Computational Fluid Dynamics (CFD) simulations are increasingly employed to model and optimize airflow patterns, minimizing pressure drops and ensuring uniform air distribution across the heat transfer surfaces.

Advanced heat exchanger designs incorporate features such as:

- Streamlined Housings: Aerodynamically designed housings with smooth contours and tailored air-inlet configurations can reduce pressure losses and improve airflow efficiency.

- Optimized Fan Arrangements: Innovative fan placements and blade designs, combined with variable-speed drives, enable precise control over airflow, leading to enhanced heat transfer and reduced energy consumption.

- Integrated Air Guides: Strategically placed air guides and baffles within the heat exchanger housing can direct and distribute the airflow for optimal heat transfer performance.

By leveraging these design innovations, air-cooled heat exchangers can achieve higher heat transfer rates, lower pressure drops, and reduced fan power requirements, ultimately enhancing their overall thermal efficiency.

Improving Durability and Reliability through Enhanced Materials and Coatings

The harsh operating environments often encountered by air-cooled heat exchangers demand robust and durable solutions to ensure reliable performance and extended service life. Advancements in materials science and surface treatment technologies have enabled the development of air-cooled heat exchangers that are more resistant to corrosion, erosion, and fouling.

Corrosion-Resistant Materials

Exposure to various chemical agents, humidity, and temperature fluctuations can accelerate the deterioration of heat exchanger materials. Stainless steel, titanium, and specialized alloys have emerged as effective solutions to combat corrosion, offering enhanced resistance to oxidation, pitting, and stress cracking.

Furthermore, the incorporation of sacrificial anode systems or the application of specialized coatings, such as chromium, nickel, or ceramic-based materials, can further protect the heat exchanger’s structural integrity and longevity.

Erosion-Resistant Surfaces

Air-cooled heat exchangers, particularly in industrial settings, can experience accelerated wear due to particulate-laden airstreams or high-velocity fluid flows. The use of erosion-resistant materials, such as tungsten carbide or diamond-like carbon coatings, can significantly enhance the durability of the heat transfer surfaces, reducing the risk of premature degradation and performance loss.

Fouling Mitigation Strategies

Fouling, the accumulation of deposits on heat transfer surfaces, can drastically impair the efficiency and reliability of air-cooled heat exchangers. Innovative approaches to address fouling include:

- Self-Cleaning Surfaces: Hydrophobic or superhydrophobic coatings can minimize the adhesion of contaminants, enabling the heat exchanger to self-clean through the action of airflow or water washing.

- Automated Cleaning Systems: Integrated cleaning mechanisms, such as high-pressure water jets or rotating brushes, can periodically remove accumulated deposits, maintaining optimal heat transfer performance.

- Advanced Monitoring and Predictive Maintenance: Integrated sensors and data analytics can provide real-time monitoring of fouling levels, allowing for proactive maintenance and cleaning schedules to be implemented, optimizing the heat exchanger’s performance and uptime.

By incorporating these durability-enhancing features, air-cooled heat exchangers can withstand the rigors of industrial environments, ensuring reliable and long-lasting operation, ultimately reducing maintenance costs and downtime.

Enhancing Environmental Sustainability through Innovative Design and Heat Recovery Strategies

Driven by the global push for sustainability and environmental stewardship, the air-cooled heat exchanger industry has made significant strides in developing solutions that minimize environmental impact and contribute to energy efficiency.

Reduced Refrigerant Charges and Transition to Natural Refrigerants

Conventional air-cooled heat exchangers often rely on synthetic refrigerants with high global warming potential (GWP). Manufacturers are now pivoting towards refrigerants with lower GWP, such as natural refrigerants like ammonia (R717), carbon dioxide (R744), and hydrocarbons (R290 and R600a), to align with evolving environmental regulations and sustainability goals.

The use of these natural refrigerants, coupled with innovative designs that optimize refrigerant charge sizes, can significantly reduce the overall environmental impact of air-cooled heat exchanger systems.

Waste Heat Recovery and Utilization

Air-cooled heat exchangers offer opportunities to capture and repurpose waste heat, thereby improving overall energy efficiency and reducing carbon emissions. Innovative heat recovery strategies include:

- Integrated Heat Pumps: Air-cooled heat exchangers can be coupled with heat pump systems to capture the rejected heat and utilize it for space heating, water heating, or industrial process heating, thereby maximizing the overall system efficiency.

- Thermal Energy Storage: The integration of thermal energy storage tanks enables the captured waste heat to be stored and subsequently used for heating or power generation, reducing the reliance on fossil fuels.

- Cogeneration and Trigeneration: Air-cooled heat exchangers can be seamlessly integrated into cogeneration or trigeneration systems, where the waste heat is used to generate steam or electricity, further enhancing the overall energy efficiency of the industrial facility.

Advancements in Modular and Scalable Designs

The development of modular and scalable air-cooled heat exchanger designs has enabled more flexible and adaptable thermal management solutions. These designs allow for easy installation, expansion, and retrofitting, making it possible to optimize the heat exchanger capacity and configuration to match the evolving needs of industrial facilities.

This modularity, coupled with the incorporation of advanced controls and automation, enables air-cooled heat exchanger systems to operate more efficiently, adapt to changing load requirements, and minimize energy consumption over their lifetime.

Maintaining Peak Performance through Comprehensive Maintenance and Optimization Strategies

Ensuring the long-term efficiency and reliability of air-cooled heat exchangers requires a comprehensive approach to maintenance and performance optimization. Adopting best practices and leveraging emerging technologies can help industrial facilities maintain their air-cooled heat exchanger systems at their peak performance.

Predictive Maintenance and Condition Monitoring

Advances in sensor technologies and data analytics have enabled the implementation of predictive maintenance strategies for air-cooled heat exchangers. By continuously monitoring key parameters, such as vibration, temperature, and pressure, facility managers can detect early signs of degradation or impending failures, allowing for proactive maintenance and minimizing unplanned downtime.

Integration of these condition monitoring systems with advanced analytics and machine learning algorithms can provide valuable insights into the heat exchanger’s health, enabling predictive maintenance scheduling and optimizing the overall maintenance strategy.

Automated Cleaning and Fouling Prevention

Regular cleaning and fouling prevention are crucial for maintaining the optimal thermal performance of air-cooled heat exchangers. Automated cleaning systems, equipped with high-pressure water jets or rotating brushes, can periodically remove accumulated deposits without the need for manual intervention, ensuring consistent heat transfer efficiency.

Additionally, the use of self-cleaning surfaces, as mentioned earlier, can further enhance the heat exchanger’s ability to maintain its performance over time, reducing the frequency and costs associated with manual cleaning.

Performance Optimization through Advanced Controls

Integrating air-cooled heat exchanger systems with advanced control systems and intelligent algorithms can unlock significant performance and energy efficiency improvements. Features such as variable-speed fan controls, automated air-flow adjustments, and real-time performance monitoring can dynamically optimize the heat exchanger’s operation based on changing load conditions and ambient factors.

These intelligent control systems can also be coupled with Building Management Systems (BMS) or Industrial Control Systems (ICS) to provide a holistic approach to thermal management, ensuring the air-cooled heat exchangers operate at their peak efficiency while contributing to the overall energy optimization of the industrial facility.

Conclusion: Unlocking the Full Potential of Air-Cooled Heat Exchangers

As the demand for efficient and sustainable thermal management solutions continues to grow, the air-cooled heat exchanger industry is at the forefront of innovation, delivering cutting-edge technologies and strategies to enhance performance, durability, and environmental responsibility.

By leveraging advanced materials, optimizing heat exchanger designs, and implementing comprehensive maintenance and optimization practices, industrial facilities can unlock the full potential of their air-cooled heat exchanger systems. These advancements not only improve thermal efficiency and reliability but also contribute to reducing energy consumption, minimizing environmental impact, and supporting the global shift towards a more sustainable future.

As an industry leader in air-cooled heat exchanger solutions, the Air Cooled Heat Exchangers blog is dedicated to providing our readers with the latest insights, practical tips, and expert guidance to stay ahead of the curve in this rapidly evolving landscape. We invite you to explore our comprehensive resources and connect with our team of seasoned professionals to unlock the true potential of your air-cooled heat exchanger systems.