Cutting-Edge Techniques for Improving Air-Cooled Heat Exchanger Durability, Maintainability, and Energy Efficiency in Industrial Applications

Optimizing Air-Cooled Heat Exchanger Performance for Enhanced Sustainability and Reliability

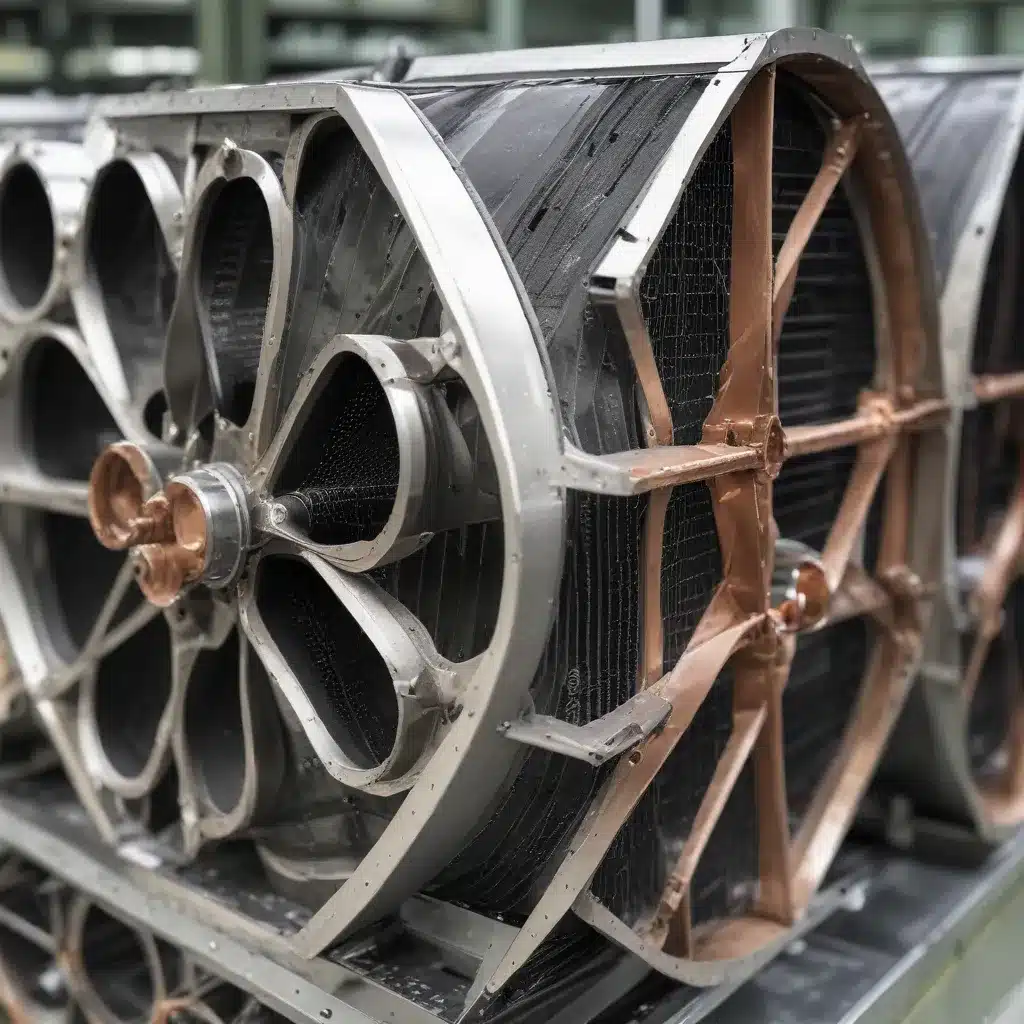

Air-cooled heat exchangers play a pivotal role in maintaining the efficiency and productivity of modern industrial operations. These robust thermal management solutions are essential for dissipating excess heat generated by machinery, processes, and equipment, ensuring optimal operating conditions and extended equipment lifespan. As industries seek to enhance sustainability, energy efficiency, and reliability, understanding the latest advancements in air-cooled heat exchanger design, engineering, and maintenance practices is crucial.

Enhancing Durability and Longevity

Leveraging Cutting-Edge Materials and Coatings

The durability and longevity of air-cooled heat exchangers are heavily influenced by the materials used in their construction. Innovative materials like high-purity graphite and advanced ceramic coatings are transforming the industry, offering unparalleled resistance to corrosion, oxidation, and thermal stress. Alfa Laval’s portfolio of air-cooled heat exchangers incorporates these cutting-edge materials, ensuring superior long-term performance even in the most demanding industrial environments.

Optimizing Thermal Management Design

The design of an air-cooled heat exchanger plays a critical role in its durability and overall performance. Leveraging computational fluid dynamics (CFD) simulations, engineers can optimize airflow patterns, heat transfer coefficients, and component geometries to minimize thermal stresses and enhance heat dissipation efficiency. Advancements in thermal modeling enable the development of air-cooled heat exchangers that can withstand the rigors of industrial applications while maintaining consistent, reliable operation.

Integrating Robust Maintenance Practices

Proper maintenance is essential for ensuring the long-term durability and performance of air-cooled heat exchangers. Implementing preventative maintenance programs, regular inspections, and timely replacement of critical components can significantly extend the lifespan of these vital industrial assets. Alfa Laval’s comprehensive service offerings provide expert support throughout the operational life of air-cooled heat exchangers, ensuring peak efficiency and preventing potential issues.

Improving Maintainability and Operational Flexibility

Modular Design for Effortless Maintenance

Innovative air-cooled heat exchanger designs are incorporating modular components that facilitate easy servicing and replacement. This approach allows for the swift and cost-effective repair or upgrade of individual parts, minimizing downtime and maximizing operational flexibility. By investing in heat exchangers with modular designs, industrial facilities can streamline maintenance activities and ensure uninterrupted thermal management.

Automated Cleaning and Fouling Prevention

Fouling, the accumulation of deposits on heat exchanger surfaces, can significantly impair heat transfer efficiency and increase operational costs. Advancements in automated cleaning systems and anti-fouling coatings are revolutionizing the maintenance of air-cooled heat exchangers. Alfa Laval’s Contherm® scraped surface heat exchangers, for example, feature rotating scraping blades that continuously remove fouling deposits, ensuring consistent heat transfer and reduced maintenance requirements.

Intelligent Monitoring and Predictive Maintenance

The integration of IoT sensors and advanced analytics into air-cooled heat exchanger systems is transforming maintenance practices. By continuously monitoring critical parameters such as temperature, vibration, and pressure, facility managers can detect potential issues before they escalate, allowing for proactive maintenance and repairs. This data-driven approach to predictive maintenance not only enhances equipment reliability but also optimizes operational costs and minimizes unplanned downtime.

Driving Energy Efficiency and Sustainability

Optimizing Airflow and Fan Performance

The energy efficiency of air-cooled heat exchangers is heavily influenced by the design and performance of their fans. Advancements in fan blade aerodynamics, motor efficiency, and variable-speed control enable the development of air-cooled heat exchangers that consume less energy while maintaining optimal heat dissipation. By investing in these energy-efficient solutions, industrial facilities can significantly reduce their carbon footprint and operational costs.

Improving Heat Transfer Coefficients

Enhancing the heat transfer capabilities of air-cooled heat exchangers is crucial for maximizing energy efficiency. Innovative fin designs, tube geometries, and advanced surface coatings can increase the overall heat transfer coefficient, allowing for more effective heat dissipation with reduced energy input. Alfa Laval’s extensive heat exchanger portfolio offers a diverse range of solutions tailored to specific industry requirements, ensuring optimal thermal management and energy savings.

Integrating Renewable Energy Sources

The integration of renewable energy sources, such as solar photovoltaic systems, into air-cooled heat exchanger operations can further enhance the sustainability of industrial thermal management. By leveraging clean energy to power the fans and auxiliary systems, industrial facilities can reduce their reliance on grid-supplied electricity, lowering their carbon footprint and operating costs.

Addressing Emerging Trends and Applications

Adaptation to Extreme Environments

As industries expand their operations into challenging environments, the demand for air-cooled heat exchangers that can withstand extreme conditions continues to grow. Manufacturers are developing solutions capable of operating in high-temperature, high-humidity, or corrosive settings, ensuring reliable thermal management in even the most demanding industrial applications.

Hybrid Cooling Systems

The integration of air-cooled heat exchangers with other cooling technologies, such as evaporative or water-cooled systems, is giving rise to hybrid cooling solutions. These hybrid systems leverage the strengths of different cooling approaches to optimize energy efficiency, reduce water consumption, and enhance overall system reliability, particularly in areas with limited water availability or high ambient temperatures.

Advancing Air-Cooled Heat Exchanger Design

The continued evolution of air-cooled heat exchanger design is driven by the need for more compact, lightweight, and versatile solutions. Advancements in materials, manufacturing techniques, and computational modeling are enabling the development of innovative heat exchanger configurations that can be tailored to specific industry requirements, further enhancing the adaptability and performance of these critical thermal management systems.

By embracing the latest trends and technologies in air-cooled heat exchanger design, engineering, and maintenance, industrial facilities can unlock unprecedented levels of durability, maintainability, and energy efficiency. These cutting-edge solutions not only enhance the reliability and sustainability of industrial operations but also contribute to the ongoing pursuit of a more environmentally responsible future. To learn more about how https://www.aircooledheatexchangers.net/ can help you optimize your air-cooled heat exchanger performance, explore our comprehensive resources and expert guidance.