Maximizing Thermal Efficiency and Extending Equipment Longevity

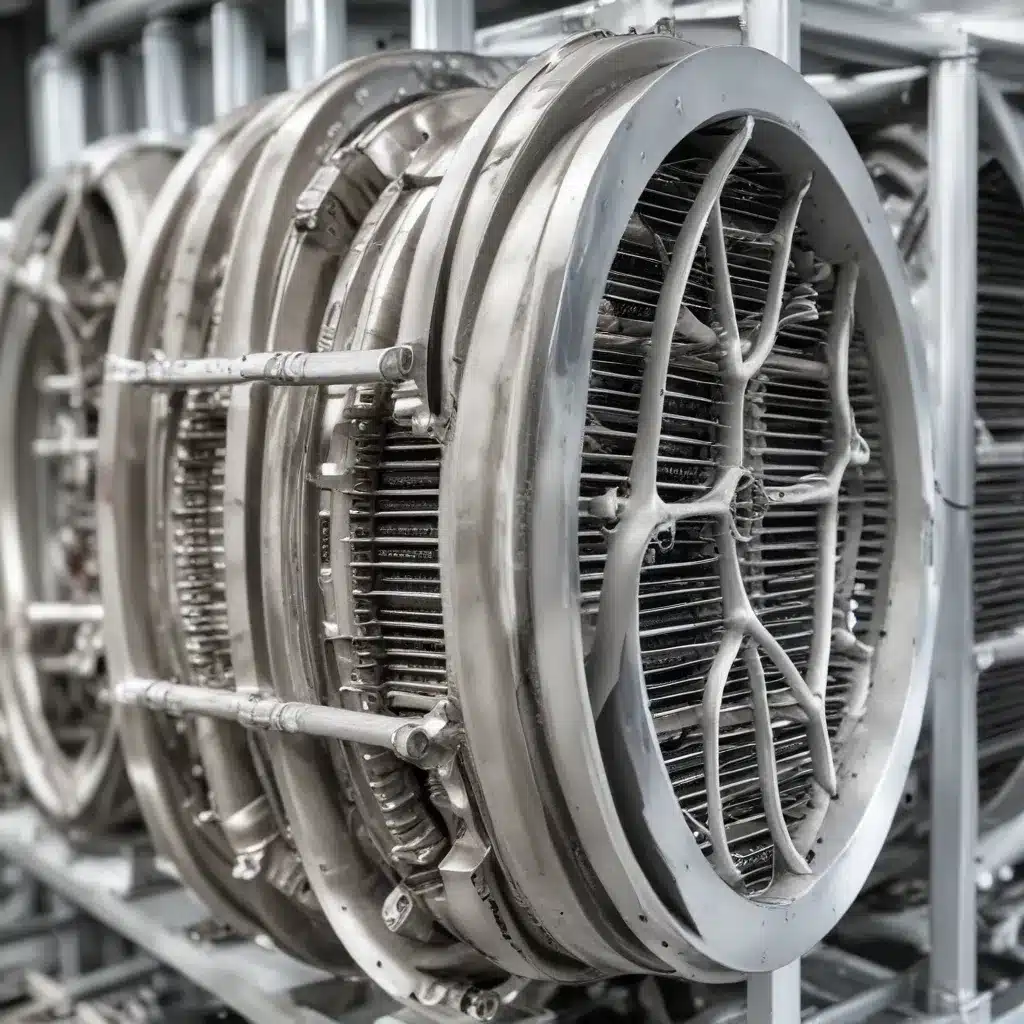

Air-cooled heat exchangers play a crucial role in various industrial processes, from power generation to petrochemical refineries. As equipment ages, however, performance degradation becomes a significant challenge, leading to increased energy consumption, reduced cooling capacity, and shortened operational lifespans. Fortunately, recent advancements in materials science and heat transfer technology have unlocked new strategies for maintaining and optimizing the efficiency of air-cooled heat exchangers.

In this comprehensive guide, we’ll explore breakthrough techniques that can dramatically improve the lifespan and thermal performance of your air-cooled heat exchangers, helping you achieve greater energy savings, reduced maintenance costs, and enhanced asset sustainability.

Harnessing the Power of Nanobubbles for Enhanced Heat Transfer

One of the most exciting developments in the realm of thermal management is the emergence of nanobubble technology. Researchers have discovered that the introduction of nanobubbles into heat transfer fluids (HTFs) can significantly enhance heat transfer efficiency, leading to substantial improvements in overall system performance.

A recent study focused on the impact of nanobubbles on HTF properties, revealing remarkable findings. The researchers observed that the presence of nanobubbles in the HTF increased the flash point by 46.15% and the fire point by 9.91% compared to the baseline fluid. Additionally, the thermal conductivity of the nanobubbled HTF improved by 11%, a significant enhancement that directly translates to more efficient heat transfer.

The experimental setup involved mechanical stirring of the HTF to simulate an isothermal state, with continuous temperature monitoring throughout the process. The striking results showcase the transformative potential of nanobubble technology in revolutionizing heat transfer fluids and, by extension, the performance of air-cooled heat exchangers.

By incorporating nanobubble-enhanced HTFs into your air-cooled heat exchangers, you can expect to see a marked increase in thermal efficiency, reduced energy consumption, and improved operational reliability. This breakthrough approach represents a significant step forward in the quest for sustainable and high-performance thermal management solutions.

Combating Fouling and Enhancing Surface Activation with CRYOGENX4

Another innovative strategy for extending the lifespan and optimizing the performance of air-cooled heat exchangers is the use of CRYOGENX4, a cutting-edge heat transfer technology.

CRYOGENX4 is a highly conductive, electromagnetic, and polarized molecule that immediately displaces the insulating layer of all ferrous and non-ferrous materials within the heat exchanger’s components, including the compressor, condenser, and evaporator. This process creates a metal surface free of fouling and capacity-robbing contaminants, significantly enhancing the heat transfer properties of the system.

The benefits of CRYOGENX4 are numerous:

- Activation and Stabilization of Heat Exchanger Surfaces: CRYOGENX4 activates and stabilizes the heat exchanger (coil) surfaces, improving heat transfer cooling capacity for the equipment’s lifetime.

- Improved Lubricity: CRYOGENX4 enhances lubricity, preventing compressor metal surfaces from seizing under extreme pressure and improving seal integrity.

- Increased Energy Efficiency: The improved heat transfer and reduced compressor cycling result in a 15-25% reduction in energy consumption, with a guaranteed 2-year payback period.

- Extended Equipment Lifespan: By addressing the root causes of performance degradation, CRYOGENX4 extends the operational lifespan of air-cooled heat exchangers, reducing the need for premature equipment replacement.

Independently tested by leading laboratories, including UL, the DOE, and the National Science Foundation, CRYOGENX4 has consistently demonstrated its ability to restore lost cooling capacity and enhance the overall efficiency of HVAC systems. With a proven track record of success across numerous Fortune 500 client case studies, this breakthrough technology offers a reliable and disruption-free solution for improving air-cooled heat exchanger performance and sustainability.

Harnessing Passive Techniques for Enhanced Heat Transfer

In addition to the innovative technologies discussed, the research community has also focused on passive approaches to enhancing heat transfer in air-cooled heat exchangers. These methods, which do not require external energy input, have the potential to provide significant improvements in thermal efficiency without increasing operational complexity.

One particularly promising area of research involves the use of nanofluids, which are fluids enhanced with the addition of nanoparticles. These nanofluids have been shown to exhibit superior thermal properties, leading to enhanced heat transfer coefficients and reduced thermal resistance. By incorporating nanofluids into the air-cooled heat exchanger’s cooling circuits, operators can expect to see tangible improvements in overall thermal performance.

Another passive technique that has gained traction is the use of corrugated heat exchanger channels partially filled with porous media. The synergistic effects of the flow Reynolds number and the thickness of the porous layer have been found to significantly enhance heat transfer, with researchers reporting substantial improvements in thermal efficiency.

These passive approaches, combined with the advancements in nanobubble technology and CRYOGENX4, offer a comprehensive toolkit for air-cooled heat exchanger optimization. By strategically combining these techniques, operators can unlock unprecedented levels of thermal efficiency, energy savings, and extended equipment lifespan.

Proactive Maintenance and Monitoring for Optimal Performance

While technological advancements are crucial, effective maintenance and monitoring practices are equally essential for ensuring the long-term performance and reliability of air-cooled heat exchangers. Adopting a proactive approach to maintenance can help identify and address potential issues before they escalate, ultimately extending the equipment’s operational lifespan.

Key maintenance strategies include:

- Regular Inspections: Routine visual inspections of the heat exchanger’s components, such as the coils, fans, and structural integrity, can help detect early signs of deterioration or fouling.

- Cleaning and Fouling Mitigation: Implementing a comprehensive cleaning regimen, including the use of specialized cleaning agents and techniques, can effectively remove accumulated debris and contaminants, restoring heat transfer efficiency.

- Vibration and Corrosion Monitoring: Implementing vibration and corrosion monitoring systems can help identify potential mechanical issues or material degradation, allowing for timely interventions.

- Predictive Maintenance: Leveraging advanced analytics and machine learning algorithms to perform predictive maintenance can help anticipate equipment failures and optimize maintenance schedules, reducing unexpected downtime.

By combining these proactive maintenance practices with the innovative heat transfer enhancement techniques discussed, you can create a comprehensive strategy for maximizing the lifespan and performance of your air-cooled heat exchangers.

Embracing the Future of Sustainable Thermal Management

As the world continues to grapple with the challenges of energy efficiency and sustainability, the role of air-cooled heat exchangers becomes increasingly crucial. By embracing the breakthrough techniques outlined in this article, you can unlock new levels of thermal performance, energy savings, and extended equipment lifespan, contributing to a more sustainable industrial landscape.

Integrating nanobubble-enhanced heat transfer fluids, CRYOGENX4 technology, and passive heat transfer enhancement methods, coupled with proactive maintenance practices, can transform the way you approach air-cooled heat exchanger management. This comprehensive approach empowers you to drive down energy consumption, reduce carbon footprints, and ensure the long-term reliability of your critical thermal assets.

Ultimately, the future of air-cooled heat exchanger technology lies in the fusion of cutting-edge scientific advancements and well-informed maintenance strategies. By staying at the forefront of these innovations, you can position your organization as a leader in sustainable thermal management, paving the way for a more energy-efficient and environmentally responsible industrial landscape.

Visit