The Importance of Thermal Management in Li-Ion Batteries

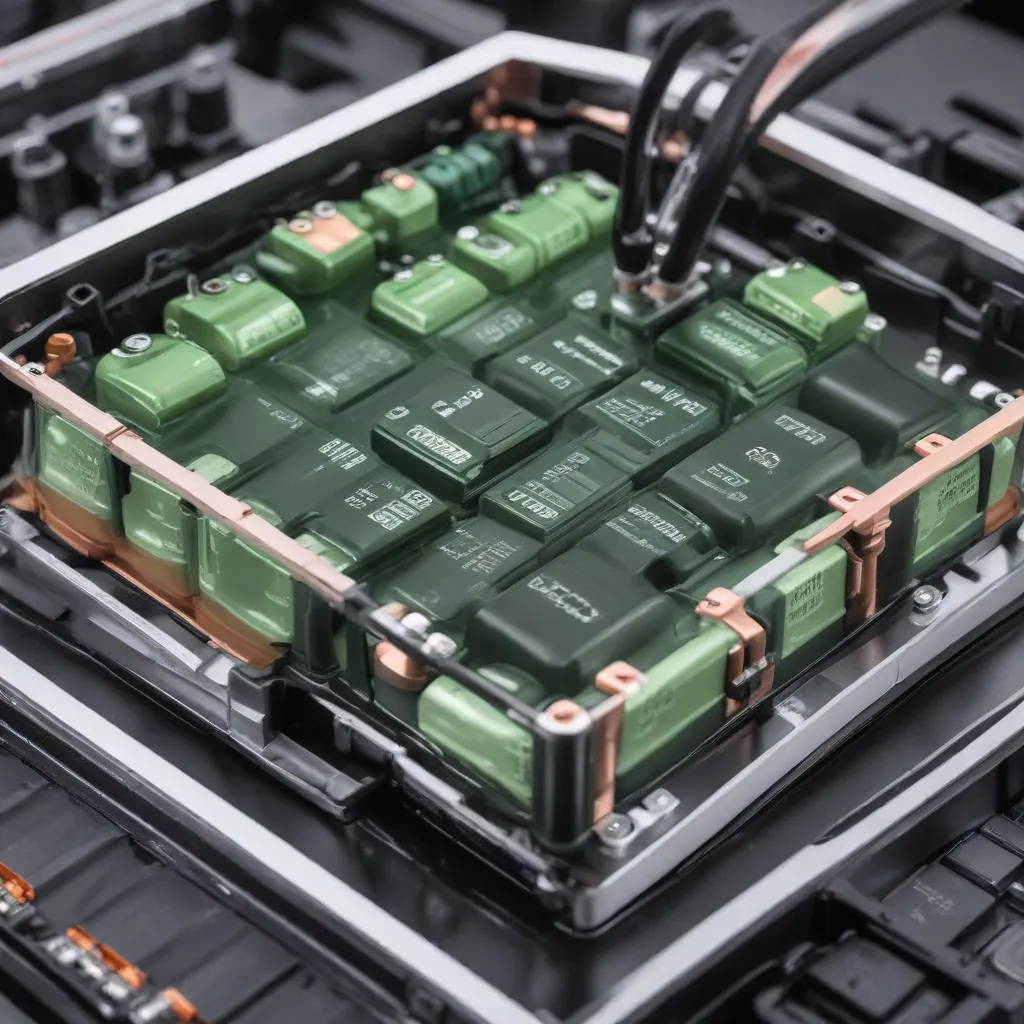

Lithium-ion (Li-ion) batteries are the backbone of modern sustainable energy solutions, powering everything from electric vehicles (EVs) to renewable energy storage systems. However, the performance and longevity of these batteries are heavily dependent on maintaining optimal operating temperatures, typically between 15°C and 35°C. Effective battery thermal management systems (BTMS) are crucial for ensuring Li-ion batteries function at their peak.

Improper thermal management can lead to a host of issues, including reduced battery capacity, accelerated degradation, safety hazards, and even catastrophic failures. As the demand for high-performance, long-lasting Li-ion batteries continues to grow, the need for innovative and efficient BTMS solutions has become paramount.

Advancements in BTMS Cooling Techniques

Researchers and engineers have been actively exploring various BTMS approaches to enhance thermal management and improve overall battery performance. These cooling methods can be broadly categorized into four main types: air-cooling, liquid-cooling, phase change material (PCM) cooling, and thermoelectric cooling.

Air-Cooling BTMS

Air-cooling is one of the most widely adopted BTMS approaches due to its simplicity and relatively low cost. Recent advancements in air-cooling BTMS have focused on improving heat transfer efficiency and uniformity across battery packs.

Improved Heat Exchanger Designs: Novel fin geometries, such as wavy or louvered fins, have been shown to enhance air-flow turbulence and increase the heat transfer coefficient, leading to more effective cooling. Additionally, the use of additive manufacturing techniques has enabled the creation of complex, optimized fin structures that further boost cooling performance.

Hybrid Air-Cooling Systems: Combining air-cooling with other cooling methods, such as liquid-cooling or PCM-cooling, can create synergistic effects and improve overall thermal management. For example, a hybrid system that uses air-cooling for the majority of the battery pack and liquid-cooling for high-heat-generation areas can effectively maintain uniform temperatures across the entire battery system.

Advanced Control Strategies: Incorporating smart, adaptive control algorithms that dynamically adjust air-flow rates and fan speeds based on real-time battery temperature and load conditions can significantly enhance the efficiency of air-cooling BTMS.

Liquid-Cooling BTMS

Liquid-cooling systems offer superior heat transfer capabilities compared to air-cooling, making them a popular choice for high-performance applications, such as in high-power EVs.

Improved Coolant Channels: Advancements in manufacturing techniques, such as additive manufacturing and microchannel fabrication, have enabled the creation of more complex and efficient coolant flow paths within the battery pack. This includes features like serpentine channels, pin-fin arrays, and microchannels, which can increase the heat transfer surface area and enhance fluid turbulence for better cooling.

Hybrid Liquid-Cooling Designs: Combining liquid-cooling with other cooling methods, such as air-cooling or PCM-cooling, can provide a well-rounded thermal management solution. For instance, a hybrid system that uses liquid-cooling for the battery core and air-cooling for the peripheral regions can effectively manage hot spots and maintain uniform temperature distribution.

Advanced Coolant Fluids: The introduction of innovative coolant fluids, such as nanofluids or phase change slurries, can further improve the heat transfer capabilities of liquid-cooling BTMS. These advanced coolants can enhance the thermal conductivity and heat capacity, leading to more efficient and reliable thermal management.

PCM-Cooling BTMS

Phase change materials (PCMs) have gained significant attention in BTMS due to their ability to absorb and release large amounts of latent heat during the phase change process, effectively buffering against temperature fluctuations.

Improved PCM Thermal Properties: Researchers have been exploring various PCM materials, including organic compounds, eutectics, and composite PCMs, to enhance thermal conductivity, increase latent heat capacity, and optimize the phase change temperature range for optimal battery performance.

Innovative PCM Encapsulation: Advancements in encapsulation techniques, such as microencapsulation and macroencapsulation, have improved the physical and chemical stability of PCMs, enabling their integration into battery packs without leakage or degradation concerns.

Hybrid PCM-Cooling Systems: Combining PCM-cooling with other cooling methods, such as air-cooling or liquid-cooling, can create synergistic effects and provide more robust thermal management. For example, a hybrid system that uses PCMs to handle peak load conditions and air-cooling for steady-state operation can effectively manage both transient and continuous thermal loads.

Thermoelectric-Cooling BTMS

Thermoelectric cooling, based on the Peltier effect, offers a unique approach to BTMS that can provide both heating and cooling capabilities, making it suitable for a wide range of operating conditions.

Improved Thermoelectric Module Efficiency: Ongoing research and development in thermoelectric materials, device design, and manufacturing processes have led to significant improvements in the efficiency and power density of thermoelectric cooling modules, making them more viable for BTMS applications.

Hybrid Thermoelectric-Cooling Systems: Integrating thermoelectric cooling with other BTMS techniques, such as liquid-cooling or PCM-cooling, can create complementary cooling effects and enhance the overall thermal management performance. For instance, a hybrid system that uses thermoelectric cooling for targeted hot spot mitigation and liquid-cooling for the broader battery pack can provide a comprehensive thermal management solution.

Advanced Control and Integration: The incorporation of smart control algorithms and seamless integration of thermoelectric cooling modules within the battery pack can optimize the system’s performance and energy efficiency, further enhancing the viability of thermoelectric-cooling BTMS.

Hybrid BTMS: The Future of Thermal Management

While the individual cooling methods mentioned above have their own strengths and weaknesses, the most promising advancements in BTMS often involve hybrid approaches that combine two or more of these techniques. These hybrid BTMS solutions leverage the complementary benefits of different cooling methods to achieve enhanced thermal management and improved overall battery performance.

Synergistic Cooling Effects: By combining cooling techniques, hybrid BTMS can create synergistic effects that exceed the capabilities of any single cooling method. For example, a hybrid system that integrates air-cooling for the majority of the battery pack and liquid-cooling for high-heat-generation areas can effectively manage both uniform temperature distribution and localized hot spots.

Improved Reliability and Redundancy: Hybrid BTMS designs often incorporate multiple cooling subsystems, providing redundancy and improved reliability. If one cooling method experiences a failure or is unable to handle the thermal load, the other subsystems can seamlessly take over, ensuring continuous and reliable thermal management.

Adaptive and Intelligent Control: The integration of advanced control algorithms and sensors in hybrid BTMS allows for dynamic, real-time adjustment of the cooling strategy based on changing battery conditions, environmental factors, and power demands. This adaptive control can optimize energy efficiency, extend battery life, and enhance overall system performance.

As the demand for high-performance, long-lasting Li-ion batteries continues to grow, the development of innovative and efficient BTMS solutions will be crucial. The recent advancements in air-cooling, liquid-cooling, PCM-cooling, and thermoelectric-cooling techniques, as well as the emergence of hybrid BTMS designs, have significantly improved the thermal management capabilities of Li-ion battery systems.

By leveraging these cutting-edge BTMS technologies, battery manufacturers and system integrators can unlock the full potential of Li-ion batteries, ensuring reliable, safe, and efficient energy storage solutions that are essential for the transition to a more sustainable future.

To learn more about the latest advancements in air-cooled heat exchangers and their applications, be sure to visit https://www.aircooledheatexchangers.net/.