Unlocking Efficient Heat Transfer with Cutting-Edge Air-Cooled Heat Exchanger Technology

In today’s rapidly evolving industrial landscape, optimizing energy efficiency and ensuring reliable thermal management are paramount concerns for businesses across diverse sectors. From power generation and petrochemical processing to HVAC systems and food manufacturing, the effective dissipation of heat is a critical challenge that requires innovative solutions tailored to the unique demands of each application.

Enter the air-cooled heat exchanger – a versatile and increasingly indispensable thermal management tool that is revolutionizing the way industries approach heat transfer. By leveraging the power of air-based cooling, these advanced heat exchangers are redefining the boundaries of efficiency, durability, and sustainability, empowering organizations to overcome their most complex thermal challenges.

Understanding the Fundamentals of Air-Cooled Heat Exchangers

At the heart of an air-cooled heat exchanger lies a simple yet ingenious principle: the transfer of thermal energy between two fluids without direct mixing. This process involves the circulation of a hot fluid, such as a process stream or a coolant, on one side of a conducting surface, typically made of metal. On the opposing side, a cooler fluid, usually ambient air, is introduced.

As the two fluids pass in close proximity, heat is transferred from the hotter medium to the cooler one through a combination of conduction, convection, and radiation, depending on the heat exchanger’s design. This exchange results in a temperature adjustment on both sides, effectively cooling the hot fluid and heating the cooler one, achieving the desired thermal management outcome.

The versatility of air-cooled heat exchangers lies in their ability to be tailored to meet the unique requirements of a wide range of industrial applications. From compact, fin-and-tube designs to large, modular configurations, these innovative thermal management solutions can be engineered to handle a diverse array of heat loads, fluid types, and operational conditions.

Advancing Air-Cooled Heat Exchanger Design and Performance

In the pursuit of enhanced efficiency and reliability, the engineering teams at leading manufacturers like Alfa Laval have been at the forefront of air-cooled heat exchanger innovation. By leveraging their extensive expertise and a deep understanding of industry-specific needs, these experts have developed a portfolio of cutting-edge air-cooled heat exchanger technologies that are redefining the boundaries of thermal management.

Fin-and-Tube Heat Exchangers

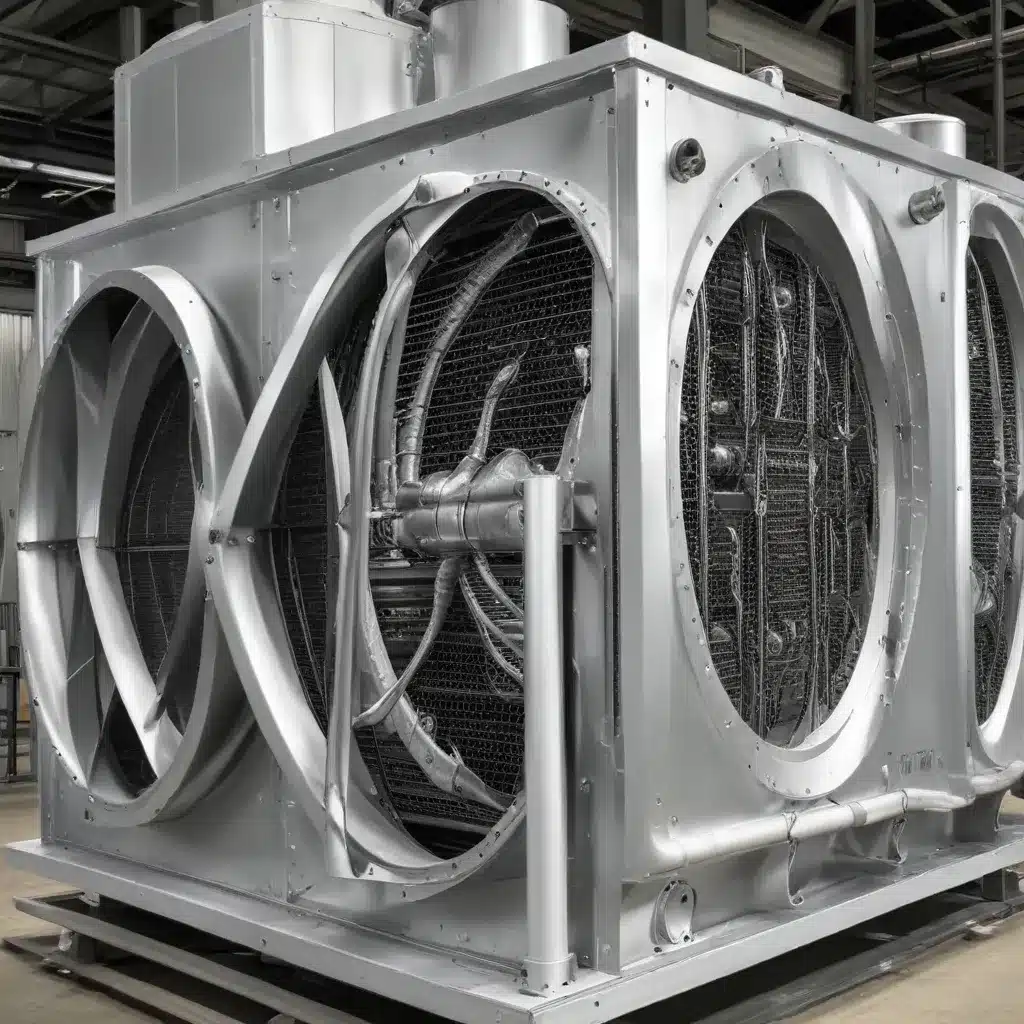

One of the most common and versatile air-cooled heat exchanger designs is the fin-and-tube configuration. In this approach, a series of metal tubes carry the hot fluid, while a network of thin, closely spaced fins surrounds the tubes, effectively increasing the surface area for heat transfer. As ambient air is drawn or pushed across the fins, it absorbs the thermal energy, dissipating it to the environment.

Fin-and-tube heat exchangers are widely used in HVAC systems, power generation, and industrial processes due to their ability to handle a wide range of heat loads and fluid types. Manufacturers have continually optimized these designs, incorporating advanced materials, specialized fin geometries, and innovative manufacturing techniques to enhance heat transfer performance, reduce energy consumption, and improve overall durability.

Modular and Customized Air-Cooled Heat Exchangers

For applications with exceptionally high heat loads or unique space constraints, modular and customized air-cooled heat exchanger designs have become increasingly popular. These solutions leverage a modular, build-to-order approach, allowing engineers to configure the heat exchanger to the specific requirements of the application.

Modular air-cooled heat exchangers can be scaled up or down in size, with the ability to combine multiple units to handle large heat loads. This flexibility enables seamless integration into a wide range of industrial settings, from power plants and oil refineries to food processing facilities and data centers.

Moreover, the customization capabilities of these advanced heat exchangers allow manufacturers to optimize the design for factors such as airflow, pressure drop, and thermal performance, ensuring the most efficient and effective thermal management solution for each unique application.

Hybrid Cooling Approaches

In some cases, the thermal management requirements of an application may exceed the capabilities of a standalone air-cooled heat exchanger. To address these challenges, a growing number of manufacturers are incorporating hybrid cooling solutions that combine air-based and liquid-based heat transfer technologies.

These hybrid systems leverage the strengths of both cooling methods, utilizing air-cooled heat exchangers to dissipate heat from a primary liquid coolant loop. This approach not only enhances overall heat transfer efficiency but also provides a redundant cooling mechanism, improving system reliability and resilience.

Optimizing Air-Cooled Heat Exchanger Performance and Maintenance

Achieving maximum efficiency and long-term reliability from air-cooled heat exchangers requires a comprehensive understanding of maintenance best practices and performance optimization strategies. Manufacturers like Alfa Laval have developed a wealth of expertise in this domain, empowering customers to extract the full potential of their thermal management investments.

Maintenance and Troubleshooting

Proper maintenance is essential for ensuring the continuous, efficient operation of air-cooled heat exchangers. This includes regular inspections, cleaning of the heat transfer surfaces, and monitoring critical parameters such as airflow, pressure drop, and heat transfer rates.

By adhering to manufacturer-recommended maintenance protocols, users can mitigate the risk of fouling, corrosion, and other issues that can compromise heat exchanger performance over time. In the event of a malfunction or component failure, experienced service teams can provide prompt troubleshooting and repair services, minimizing downtime and optimizing long-term system reliability.

Performance Optimization

To further enhance the efficiency and cost-effectiveness of air-cooled heat exchangers, manufacturers offer a range of optimization services and tools. These include computational fluid dynamics (CFD) analyses to model airflow and heat transfer patterns, as well as the development of custom configurations tailored to the unique constraints and requirements of each application.

By working closely with customers, industry experts can identify opportunities for performance improvements, whether through the incorporation of advanced materials, the optimization of fin geometries, or the integration of hybrid cooling systems. These enhancements not only boost heat transfer capabilities but also contribute to reduced energy consumption and a lower environmental impact.

Embracing Air-Cooled Heat Exchangers for Sustainable Thermal Management

As industries worldwide navigate the challenges of energy efficiency, environmental responsibility, and operational resilience, air-cooled heat exchangers have emerged as a vital component of the thermal management ecosystem. These innovative solutions, backed by decades of engineering expertise and continuous technological advancements, offer a compelling pathway to addressing the most pressing thermal challenges facing modern organizations.

By leveraging the power of air-based cooling, air-cooled heat exchangers provide a robust, flexible, and sustainable approach to heat transfer that can be tailored to the unique needs of diverse industries. From enhancing the energy efficiency of HVAC systems to enabling reliable thermal management in power generation and industrial processing, these cutting-edge technologies are redefining the boundaries of what’s possible in the realm of industrial thermal management.

As the demand for innovative, cost-effective, and environmentally-conscious thermal solutions continues to grow, air-cooled heat exchangers stand poised to play a pivotal role in shaping the future of industrial thermal management. By partnering with industry-leading manufacturers and leveraging their deep expertise, organizations can unlock new levels of efficiency, reliability, and sustainability, positioning themselves for long-term success in an ever-evolving industrial landscape.