The Evolving Landscape of Automotive Thermal Management

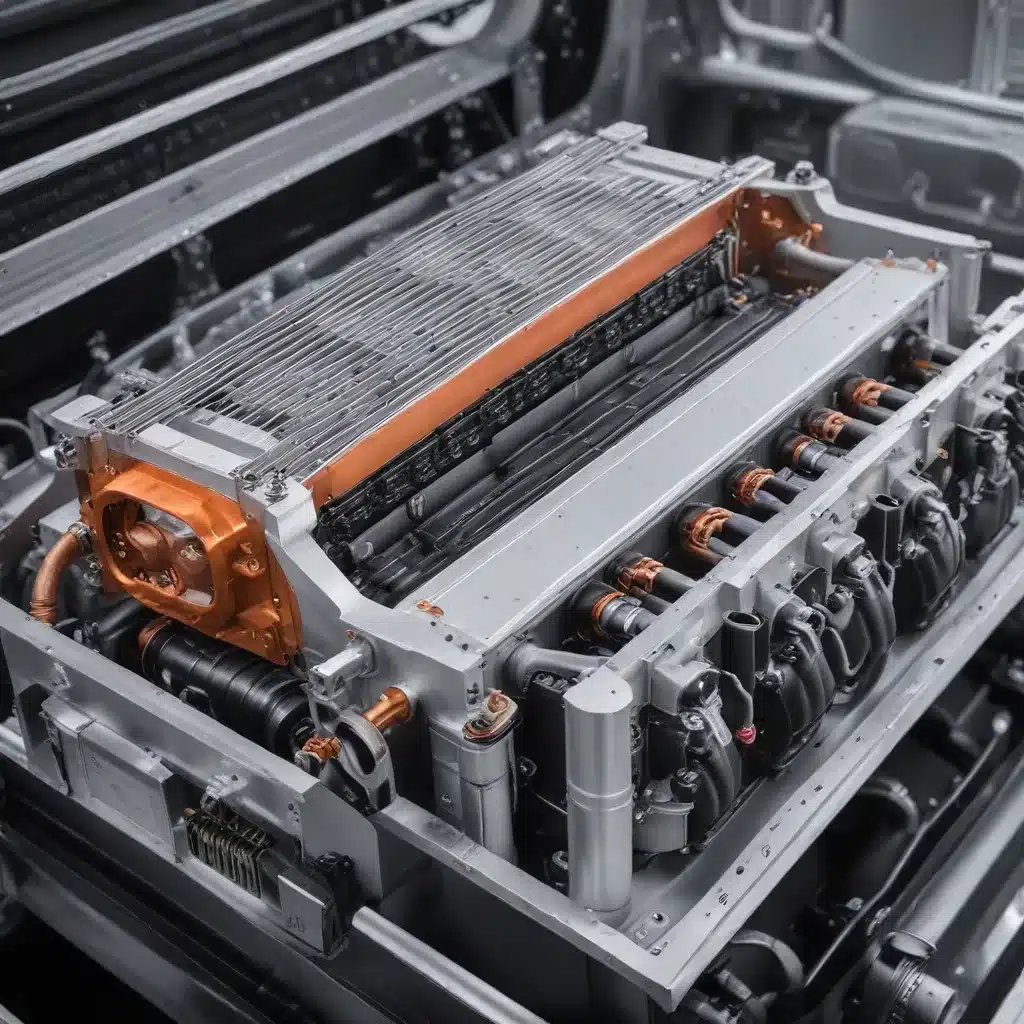

As the automotive industry undergoes a transformative shift towards electrification, the importance of effective thermal management systems has become paramount. The rise of electric vehicles (EVs) and hybrid electric vehicles (HEVs) has presented new challenges in maintaining optimal performance, reliability, and longevity of critical components, especially the battery packs.

Conventional internal combustion engine (ICE) vehicles relied on relatively straightforward cooling systems, primarily focused on maintaining the engine temperature within its optimal operating range. However, the thermal management requirements for electrified vehicles are far more complex. Battery packs, electric motors, power electronics, and other on-board systems all generate heat that must be efficiently dissipated to ensure the vehicle’s overall performance and efficiency.

The Pivotal Role of Air-Cooled Heat Exchangers

In the quest for sustainable and efficient thermal management solutions for the automotive industry, air-cooled heat exchangers have emerged as a crucial technology. These heat exchangers leverage the ambient air as the primary cooling medium, providing a cost-effective and reliable means of heat dissipation without the added complexity and weight of liquid-based cooling systems.

Air-cooled heat exchangers offer several key advantages that make them well-suited for electric and hybrid vehicle applications:

-

Simplicity and Reliability: By eliminating the need for a dedicated liquid cooling circuit, air-cooled heat exchangers reduce the overall system complexity, improving reliability and reducing maintenance requirements.

-

Lightweight Design: The absence of liquid coolant and associated components, such as pumps and hoses, allows air-cooled heat exchangers to be designed with a lightweight and compact form factor, which is crucial for maximizing the available space and minimizing the vehicle’s overall weight.

-

Energy Efficiency: Air-cooled heat exchangers operate without the added energy consumption of liquid cooling pumps, thereby contributing to the overall energy efficiency of the vehicle and enhancing the driving range of electric and hybrid models.

-

Thermal Management Versatility: Air-cooled heat exchangers can be strategically positioned throughout the vehicle to provide targeted cooling to various components, including battery packs, power electronics, and electric motors, ensuring optimal performance and longevity for each subsystem.

Unlocking the Potential of Air-Cooled Heat Exchangers

To fully harness the benefits of air-cooled heat exchangers in the automotive industry, manufacturers and designers must consider several key factors in their development and deployment:

Optimized Heat Transfer Performance

The efficiency of an air-cooled heat exchanger is largely determined by its ability to effectively transfer heat from the source (e.g., battery pack) to the ambient air. This requires careful consideration of the heat exchanger’s design, including the selection of materials, fin geometry, and airflow optimization.

Advanced computational fluid dynamics (CFD) simulations and experimental validation can help engineers identify the optimal heat exchanger configuration for a given application, ensuring efficient heat dissipation while maintaining a compact and lightweight design.

Thermal Management Integration

Integrating air-cooled heat exchangers into the overall thermal management system of an electric or hybrid vehicle requires a holistic approach. The heat exchangers must be strategically positioned and integrated with other cooling components, such as fans and ducting, to create a seamless and efficient thermal management solution.

This integration process also involves close collaboration between thermal engineers, vehicle designers, and component manufacturers to ensure the heat exchangers’ optimal performance, packaging, and compatibility with the vehicle’s overall architecture.

Durability and Reliability

The harsh operating conditions of automotive environments, including exposure to vibrations, dirt, and temperature extremes, necessitate the development of durable and reliable air-cooled heat exchanger designs. Careful material selection, advanced manufacturing techniques, and rigorous testing procedures are essential to ensure the long-term performance and dependability of these critical components.

Maintenance and Serviceability

To maintain the optimal performance of air-cooled heat exchangers throughout the vehicle’s lifetime, consideration must be given to their maintenance and serviceability. This includes designing the heat exchangers with easy access for cleaning and inspection, as well as developing maintenance guidelines to ensure the longevity of the thermal management system.

Innovative Approaches to Air-Cooled Heat Exchanger Design

The continuous evolution of the automotive industry has sparked the development of innovative air-cooled heat exchanger designs and manufacturing techniques. These advancements are driving improvements in thermal performance, weight reduction, and overall system integration.

Additive Manufacturing for Complex Geometries

The rise of additive manufacturing, or 3D printing, has opened new possibilities for the design and fabrication of air-cooled heat exchangers. By leveraging the capabilities of metal additive manufacturing, engineers can create complex, optimized heat exchanger geometries that would be challenging or impossible to produce using traditional manufacturing methods.

Conflux Technology, a leading innovator in the field of additive manufacturing, has demonstrated the impressive potential of 3D-printed air-cooled heat exchangers. Their ultra-lightweight and highly conformable cold plate heat sinks have shown exceptional thermal performance, making them well-suited for integration into advanced thermal management systems for electric vehicles.

Hybrid Cooling Approaches

While air-cooling remains a primary focus for automotive thermal management, hybrid cooling solutions that combine air-cooled and liquid-cooled components are also gaining traction. These hybrid systems can offer the best of both worlds, leveraging the simplicity and efficiency of air-cooled heat exchangers while incorporating targeted liquid cooling for specific high-heat-generating components.

Continental, a global leader in automotive technology, has been at the forefront of developing comprehensive thermal management solutions for electrified vehicles. Their expertise in integrating rubber hoses, metal pipes, and fittings enables the creation of adaptable and efficient thermal line systems that can effectively manage the complex thermal demands of electric and hybrid vehicles.

Collaborative Partnerships for Advancing Thermal Solutions

The development of cutting-edge air-cooled heat exchanger technologies for the automotive industry requires a collaborative approach among various stakeholders, including manufacturers, research institutions, and industry experts.

Creative Thermal Solutions, a renowned provider of thermal engineering services, understands the importance of fostering these collaborative partnerships. Their facilities offer a wide range of capabilities, from fundamental brazing research to large-scale prototyping, enabling the exploration and refinement of innovative air-cooled heat exchanger designs.

By working closely with automotive manufacturers, material suppliers, and thermal management specialists, companies like Creative Thermal Solutions can help drive the continuous improvement of air-cooled heat exchanger technologies, ensuring they remain at the forefront of the industry’s evolving needs.

Conclusion: The Future of Thermal Management in Electrified Vehicles

As the automotive industry accelerates its transition towards electrification, the importance of efficient and reliable thermal management systems has become increasingly critical. Air-cooled heat exchangers have emerged as a pivotal technology, offering simplicity, lightweight design, and energy-efficient cooling solutions that are well-suited for the unique challenges of electric and hybrid vehicles.

Through ongoing research, innovative design approaches, and collaborative partnerships, the air-cooled heat exchanger landscape is continuously evolving, unlocking new possibilities for thermal management in the automotive industry. By leveraging these advancements, manufacturers can deliver vehicles that optimize performance, enhance driving range, and contribute to a more sustainable and emission-free future of mobility.

Visit AirCooledHeatExchangers.net to explore more insights and practical tips on air-cooled heat exchanger technologies and their applications across various industries.