The Evolving Landscape of Automotive Thermal Engineering

As the automotive industry accelerates towards electrification and innovation, the significance of advanced thermal technologies, particularly heat exchangers, becomes increasingly critical. Heat exchangers play a pivotal role in optimizing the performance of vehicles, ranging from traditional combustion engines to the advanced battery systems powering electric vehicles (EVs), and are especially vital in the high-demand context of motorsports.

The automotive and motorsports sectors have long been at the forefront of thermal engineering, constantly pushing the boundaries of efficiency, safety, and durability. With the rise of EVs, hybrid powertrains, and hydrogen fuel cell vehicles (FCVs), the challenges faced by thermal management systems have become more complex and multifaceted. Effective cooling and heating solutions are essential to ensure optimal operating temperatures, enhance performance, and safeguard critical components in these advanced vehicle architectures.

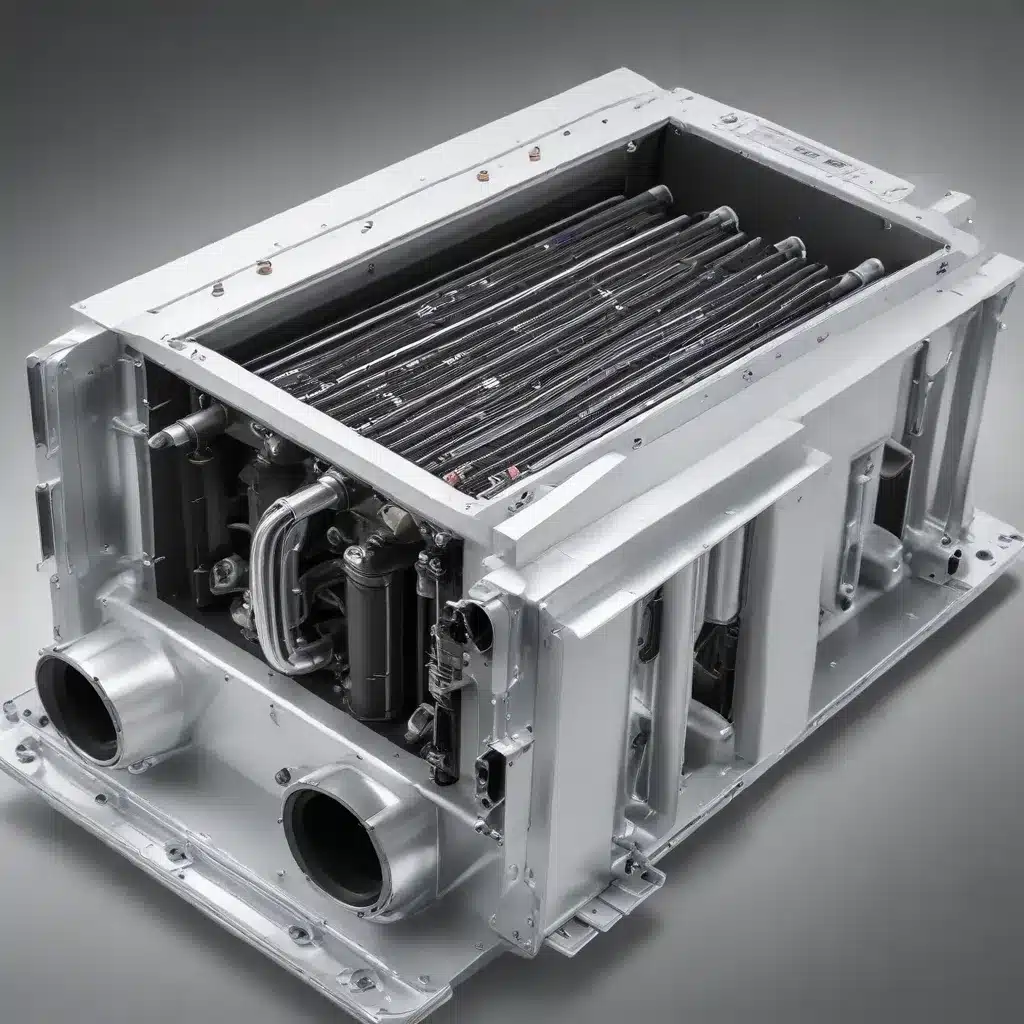

Air-Cooled Heat Exchangers: Versatile and Efficient Thermal Solutions

Air-cooled heat exchangers have emerged as a versatile and efficient solution for thermal management in the automotive industry. These heat exchangers leverage the inherent advantages of air as a cooling medium, offering numerous benefits over traditional liquid-based systems.

One of the key advantages of air-cooled heat exchangers is their enhanced surface area-to-volume ratio, which results in significantly higher thermal exchange performance. By incorporating innovative micro-structures and complex internal geometries, these heat exchangers can achieve highly efficient heat transfer while maintaining low-pressure drops, optimizing system performance through smooth fluid flow and optimal heat dissipation.

Moreover, the monolithic design of air-cooled heat exchangers can significantly reduce overall weight and simplify maintenance, streamlining system serviceability. This lightweight and integrated approach is particularly valuable in the automotive industry, where every gram of weight reduction contributes to improved efficiency and performance.

Advancing Air-Cooled Heat Exchanger Design and Manufacturing

The automotive and motorsports industries have been early adopters of cutting-edge design and manufacturing technologies, such as additive manufacturing (AM), to drive innovation in air-cooled heat exchangers. AM, also known as 3D printing, has enabled the creation of heat exchangers with unparalleled design freedom, allowing for the optimization of form factors and seamless integration into a wide range of vehicle systems.

Through the use of advanced design methodologies and AM techniques, automotive and motorsports engineers can now create air-cooled heat exchangers with morphed topologies, tailored to fit available spaces and offering unprecedented flexibility. These customized heat exchangers can deliver significant reductions in core volume, air-side pressure drop, and overall weight, providing a distinct advantage in the quest for enhanced efficiency and performance.

One such example is the ultra-high-performance water-cooled air cooler (WCAC) developed by industry leaders. When benchmarked against leading microtube WCAC designs, these cutting-edge heat exchangers have demonstrated:

- 82% reduction in water-side pressure drop

- 39% reduction in wet weight

- 24% reduction in air-side pressure drop

- 15% smaller core volume

These substantial improvements in key performance metrics highlight the transformative potential of innovative air-cooled heat exchanger technologies in the automotive and motorsports industries.

Thermal Management Solutions for Electric, Hybrid, and Fuel Cell Vehicles

The shift towards electrification and alternative powertrain architectures has brought about new thermal management challenges that air-cooled heat exchangers are uniquely positioned to address.

In electric vehicles (EVs), the thermal management of battery systems is crucial for ensuring optimal performance, safety, and longevity. Air-cooled heat exchangers can be strategically integrated into the vehicle’s thermal management system (TMS) to efficiently dissipate heat generated by the battery pack, electric motors, and power electronics. By maintaining the optimal operating temperatures of these critical components, air-cooled heat exchangers contribute to enhanced range, improved charging capabilities, and extended battery life.

Similarly, in hybrid electric vehicles (HEVs), air-cooled heat exchangers play a vital role in managing the thermal loads of both the internal combustion engine and the electric powertrain components. This dual-function capability ensures that the various systems operate within their ideal temperature ranges, optimizing overall vehicle performance and fuel efficiency.

For hydrogen fuel cell vehicles (FCVs), air-cooled heat exchangers are essential for regulating the temperature of the fuel cell stacks, electric motors, and associated power electronics. Efficient thermal management is crucial in these vehicles to maintain the fuel cell’s optimal operating conditions, maximize power output, and ensure long-term durability.

Optimizing Air-Cooled Heat Exchanger Performance

To unlock the full potential of air-cooled heat exchangers in automotive applications, a comprehensive understanding of performance optimization strategies is essential. Key areas of focus include:

Innovative Geometries and Surface Enhancements

Cutting-edge air-cooled heat exchanger designs leverage advanced micro-structures, complex internal geometries, and surface enhancements to maximize heat transfer while minimizing pressure drops. These innovative approaches, often enabled by additive manufacturing, can significantly improve thermal exchange efficiency and system-level performance.

Computational Fluid Dynamics (CFD) Modeling

Sophisticated CFD simulations play a crucial role in the design and optimization of air-cooled heat exchangers. By modeling fluid flow, heat transfer, and thermal behavior, engineers can virtually test and refine heat exchanger designs, ensuring optimal performance before physical prototyping and manufacturing.

Thermal System Integration

Integrating air-cooled heat exchangers into the broader vehicle thermal management system is crucial for maximizing overall efficiency. Careful coordination between the heat exchanger, coolant circuits, and other thermal components, such as fans and pumps, can lead to significant improvements in system-level performance and energy consumption.

Maintenance and Serviceability

Maintaining optimal air-cooled heat exchanger performance over the life of a vehicle is essential. Designing for ease of inspection, cleaning, and replacement can simplify maintenance, reduce downtime, and ensure consistent thermal management throughout the vehicle’s lifespan.

Addressing Extreme Thermal Challenges in Motorsports

The motorsports industry has long been an early adopter of advanced thermal management technologies, including air-cooled heat exchangers. The demanding operating conditions of racing environments, characterized by high-performance engines, intense braking, and extreme aerodynamic loads, push thermal systems to their limits.

By leveraging the expertise gained from Formula 1 and other top-tier motorsports, air-cooled heat exchanger solutions have been developed to meet the elevated performance demands of modern racing platforms. These advanced heat exchangers, often employing additive manufacturing techniques, are designed to provide exceptional thermal management for engine cooling, battery cooling, oil cooling, transmission cooling, brake cooling, motor cooling, and even heating and air conditioning systems.

The ability to rapidly prototype and innovate through additive manufacturing has been a game-changer for the motorsports industry, enabling teams to quickly adapt and optimize their thermal management solutions for the evolving needs of their race cars. This agility and design freedom have become crucial in the highly competitive world of motorsports, where every performance advantage can make the difference between victory and defeat.

Conclusion: Unlocking the Future of Automotive Thermal Management

As the automotive industry continues its rapid transformation, air-cooled heat exchangers are poised to play an increasingly pivotal role in the advancement of thermal management solutions. With their unparalleled design flexibility, enhanced heat transfer capabilities, and lightweight construction, these innovative heat exchangers are helping to drive the future of electric, hybrid, and fuel cell vehicle powertrain systems.

By leveraging cutting-edge technologies, such as additive manufacturing, and drawing from the wealth of experience in the motorsports industry, air-cooled heat exchangers are transforming the way automotive engineers approach thermal management challenges. These solutions are not only optimizing vehicle performance and efficiency but also enhancing safety, reliability, and sustainability across the automotive landscape.

As the industry continues to push the boundaries of what’s possible, air-cooled heat exchangers will undoubtedly play a pivotal role in shaping the future of automotive thermal management, ensuring that vehicles of tomorrow operate at their peak, no matter the powertrain technology.