Harnessing the Power of Enhanced Surfaces and Geometries for Efficient Heat Dissipation

As the demand for more compact and powerful electronic devices continues to rise, the need for effective thermal management solutions has become increasingly crucial. Traditional heat sink designs often fall short in meeting the rigorous cooling requirements of modern electronics, driving researchers and engineers to explore innovative approaches to enhance heat transfer. One such avenue is the integration of advanced fin geometries and surface modifications into air-cooled heat exchangers.

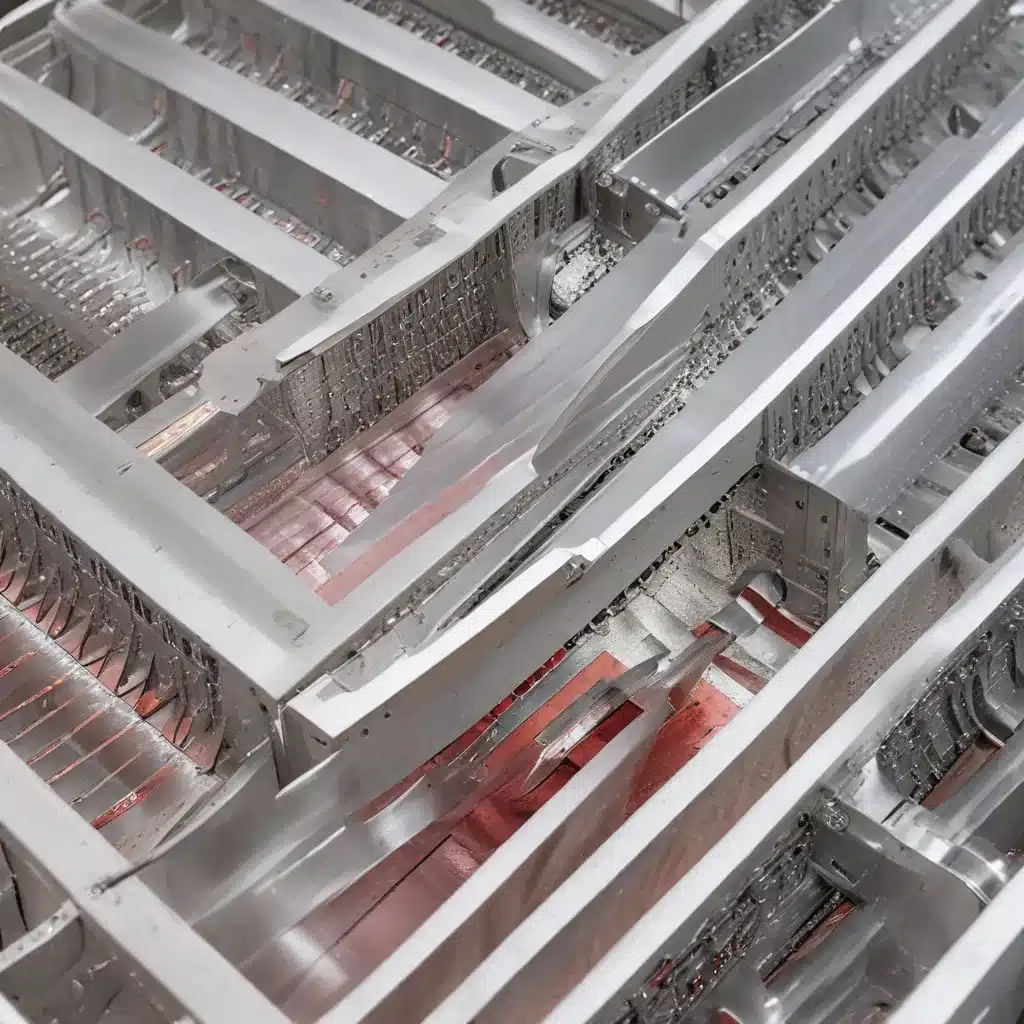

Air-cooled heat exchangers play a pivotal role in thermal management across various industries, from electronics to HVAC systems. By extending the surface area through the use of fins, these heat exchangers can significantly improve heat transfer rates, making them an attractive solution for applications where air is the primary coolant. However, the efficiency of these heat exchangers is often limited by the performance of the fins themselves, leading researchers to investigate ways to optimize the fin design and surface properties for enhanced heat transfer.

Advancing Fin Geometries: Disrupting the Boundary Layer and Promoting Turbulence

One of the key strategies for improving the performance of air-cooled heat exchangers is the incorporation of advanced fin geometries. Traditional smooth fins, while effective in increasing the surface area, can be limited in their ability to disrupt the boundary layer and promote turbulent flow, both of which are crucial for enhancing heat transfer.

Researchers have explored various fin profiles, such as curved strips, angled fins, undulating fins, and perforated fins, to address these limitations. These innovative fin designs have demonstrated the ability to induce secondary flow patterns, create swirling motions, and disrupt the thermal boundary layer, leading to significant improvements in the heat transfer rate.

The enhanced heat transfer observed with these modified fin geometries can be attributed to several factors:

-

Boundary Layer Disruption: The strategic placement of fins, such as angled or undulating profiles, can disturb the laminar boundary layer, causing it to transition to a more turbulent state. This disruption reduces the thermal resistance at the surface, enabling more efficient heat transfer.

-

Increased Fluid Mixing: The complex flow patterns generated by the modified fin geometries promote better mixing of the hot and cold fluids, leading to improved convective heat transfer and a reduction in thermal stratification.

-

Increased Surface Area: Certain fin designs, such as perforated or wavy fins, can increase the overall surface area available for heat exchange, further enhancing the heat transfer capabilities of the heat exchanger.

By incorporating these advanced fin geometries, air-cooled heat exchangers can achieve significant improvements in their thermal performance, allowing for more efficient heat dissipation and the ability to handle higher heat loads.

Harnessing the Power of Surface Modifications

In addition to exploring innovative fin designs, researchers have also focused on enhancing the heat transfer performance of air-cooled heat exchangers through surface modifications. These techniques aim to alter the properties of the heat transfer surfaces, creating conditions that are more favorable for efficient heat exchange.

One prominent approach is the use of textured or patterned surfaces. By coating or texturing the heat exchanger surfaces with features such as dimples, protrusions, or micro-scale roughness, the heat transfer can be improved through several mechanisms:

-

Boundary Layer Disruption: Similar to the effect of modified fin geometries, surface textures can disrupt the thermal boundary layer, promoting turbulence and enhancing the convective heat transfer coefficient.

-

Increased Surface Area: Textured or patterned surfaces increase the effective surface area available for heat exchange, leading to a higher rate of heat transfer.

-

Improved Fluid Mixing: The irregularities on the surface can induce secondary flow patterns and vortices, improving the mixing of hot and cold fluids and facilitating more efficient heat transfer.

Additionally, researchers have explored the use of advanced materials, such as nanoparticle coatings or hydrophobic surfaces, to further enhance the heat transfer capabilities of air-cooled heat exchangers. These surface modifications can reduce the thermal resistance, improve wetting characteristics, and promote the formation of thin boundary layers, all of which contribute to enhanced heat dissipation.

Integrating Innovative Fin Geometries and Surface Modifications

The synergistic integration of advanced fin geometries and surface modifications has emerged as a promising approach for optimizing the performance of air-cooled heat exchangers. By combining these strategies, researchers have been able to achieve even greater enhancements in heat transfer rates and overall thermal efficiency.

For instance, studies have shown that incorporating vortex generators, such as winglets or delta-wing vortex generators, on the heat exchanger surfaces can significantly improve the heat transfer characteristics. These vortex generators create secondary flow patterns that disrupt the boundary layer and promote fluid mixing, leading to substantial improvements in convective heat transfer.

Furthermore, the integration of textured or patterned surfaces with modified fin geometries has demonstrated the ability to amplify the heat transfer benefits. The combination of increased surface area, boundary layer disturbance, and enhanced fluid mixing can result in a significant increase in the overall heat transfer performance of the air-cooled heat exchanger.

By leveraging the complementary effects of innovative fin designs and surface modifications, air-cooled heat exchangers can be engineered to deliver higher heat transfer rates, improved thermal efficiency, and the ability to dissipate greater heat loads. This integration of advanced technologies paves the way for the development of more compact, energy-efficient, and versatile thermal management solutions for a wide range of applications.

Optimizing Air-Cooled Heat Exchanger Design and Performance

The journey towards enhancing the performance of air-cooled heat exchangers extends beyond the integration of innovative fin geometries and surface modifications. Researchers and engineers have also explored various other strategies to further optimize the design and operation of these critical thermal management components.

Leveraging Computational Fluid Dynamics (CFD) for Improved Design

One powerful tool that has revolutionized the design and optimization of air-cooled heat exchangers is Computational Fluid Dynamics (CFD). CFD simulations allow for the detailed modeling and analysis of fluid flow, heat transfer, and other critical processes within the heat exchanger, enabling engineers to explore a wide range of design alternatives and operating conditions.

By leveraging CFD, researchers can gain valuable insights into the complex flow patterns, temperature distributions, and heat transfer characteristics within the heat exchanger. This information can then be used to refine the design, optimize fin geometries, and explore the impact of various surface modifications, all without the need for extensive physical prototyping and testing.

Moreover, CFD simulations can also be employed to investigate the effects of fouling on the performance of air-cooled heat exchangers. By modeling the deposition of contaminants and the resulting changes in heat transfer, engineers can develop strategies to mitigate the impacts of fouling and improve the long-term reliability of these critical components.

Experimental Validation and Performance Optimization

While computational modeling provides a powerful tool for design and optimization, physical experimentation remains a crucial step in the development of high-performance air-cooled heat exchangers. Experimental studies allow researchers to validate their computational findings, refine their models, and explore the real-world performance of their designs.

Techniques such as laser light sheet illumination, naphthalene sublimation, infrared thermography, and particle image velocimetry have been employed to gain a deeper understanding of the flow patterns, heat transfer characteristics, and overall performance of air-cooled heat exchangers. These experimental methods enable the collection of detailed data on the thermal and fluid dynamics within the heat exchanger, providing valuable feedback to guide the optimization of the design.

Furthermore, experimental investigations have also been used to assess the impact of fouling on heat exchanger performance. By monitoring the changes in heat transfer coefficients, pressure drops, and other key parameters over time, researchers can develop strategies to mitigate the effects of contaminant buildup and maintain optimal heat exchanger efficiency.

Advancing Towards Practical Applications

The integration of innovative fin geometries, surface modifications, computational modeling, and experimental validation has paved the way for the development of air-cooled heat exchangers that can meet the evolving thermal management challenges across various industries.

In the electronics sector, for instance, the ability to dissipate higher heat loads while maintaining a compact footprint has become crucial. The advancements in air-cooled heat exchanger technology have enabled the design of more efficient and reliable thermal management solutions for high-performance computing, power electronics, and other energy-dense electronic systems.

Similarly, in the HVAC industry, the optimization of air-cooled heat exchangers has led to the development of more energy-efficient and environmentally friendly cooling systems. By improving the heat transfer performance and reducing pressure drops, these advanced heat exchangers can contribute to lower energy consumption and reduced carbon footprints.

Beyond the traditional applications, the innovative approaches to air-cooled heat exchanger design have also found relevance in emerging fields, such as electric vehicles and renewable energy systems. As these technologies continue to evolve, the ability to effectively manage thermal loads and optimize energy utilization becomes increasingly critical, making air-cooled heat exchangers a vital component in the quest for a more sustainable future.

Conclusion: Unlocking the Potential of Air-Cooled Heat Exchanger Technology

The advancement of air-cooled heat exchanger technology through the integration of innovative fin geometries and surface modifications has been a transformative journey. By leveraging these strategic enhancements, researchers and engineers have been able to significantly improve the heat transfer capabilities of these critical thermal management components, paving the way for more efficient, compact, and versatile solutions across a wide range of industries.

The exploration of advanced fin designs, such as curved, angled, and perforated fins, has demonstrated the ability to disrupt the boundary layer, promote fluid mixing, and increase the effective surface area for heat exchange. Similarly, the integration of textured or patterned surfaces has shown the potential to further enhance heat transfer by reducing thermal resistance and improving wetting characteristics.

The synergistic combination of these strategies has amplified the benefits, leading to unprecedented improvements in the overall thermal performance of air-cooled heat exchangers. Computational fluid dynamics (CFD) modeling and experimental validation have played a crucial role in guiding the design optimization, ensuring that these advancements translate into practical, real-world solutions.

As the demand for more effective thermal management continues to grow, the advancements in air-cooled heat exchanger technology will become increasingly vital. From the electronics industry to HVAC systems and beyond, these innovations will enable the development of more compact, energy-efficient, and sustainable thermal management solutions, driving progress in a wide range of applications.

By embracing the power of innovative fin geometries, surface modifications, and integrated design approaches, the air-cooled heat exchanger industry is poised to unlock new frontiers in thermal management, ultimately contributing to a more energy-efficient and technologically advanced future.