As the electric vehicle (EV) industry continues to evolve, effective thermal management has become increasingly crucial for ensuring battery safety, optimizing energy utilization, and prolonging vehicle lifespan. Air-cooled heat exchangers play a pivotal role in this endeavor, providing efficient and reliable thermal management solutions tailored to the unique challenges of electric vehicles.

The Importance of Thermal Management in Electric Vehicles

Electric vehicles face distinctive thermal management requirements compared to their internal combustion engine counterparts. The high-power electric motors, energy-dense battery packs, and advanced power electronics generate significant amounts of waste heat that must be effectively dissipated to maintain optimal performance and safety. Improper thermal management can lead to reduced battery life, decreased driving range, and in severe cases, thermal runaway and battery fires.

To address these challenges, the design and integration of air-cooled heat exchangers in EV thermal management systems have become a subject of growing interest and innovation. By leveraging the versatility and reliability of air-cooling technologies, engineers can develop comprehensive thermal management solutions that address the specific needs of electric vehicles.

Advancements in Air-Cooled Heat Exchanger Design for EVs

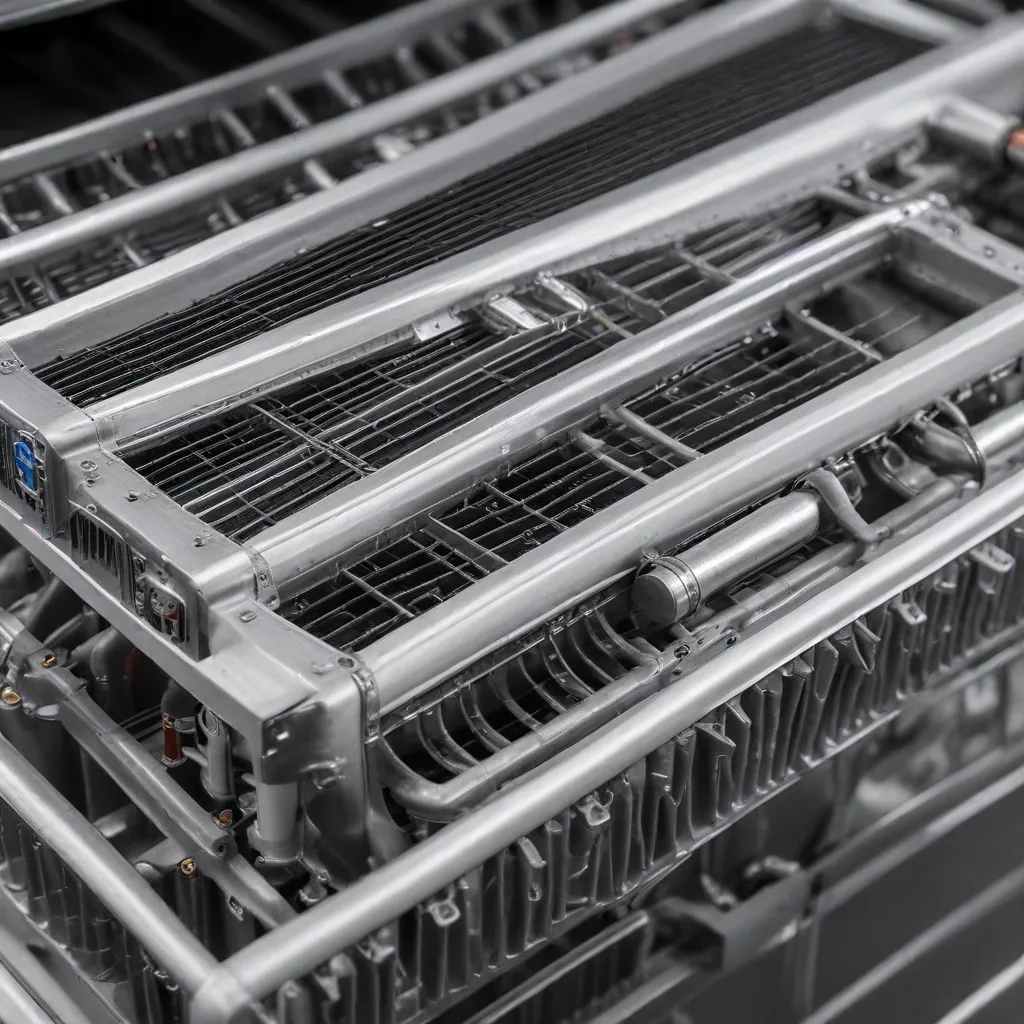

One of the key advancements in air-cooled heat exchanger technology for electric vehicles is the integration of advanced materials and manufacturing techniques. Lightweight, high-performance materials, such as aluminum alloys and specialized coatings, have been adopted to enhance the heat transfer capabilities and corrosion resistance of these heat exchangers. Additionally, innovative manufacturing processes, including additive manufacturing and optimized fin designs, have led to more efficient and compact air-cooled heat exchanger configurations.

Improved Heat Transfer Efficiency

Air-cooled heat exchangers in electric vehicles must efficiently dissipate the significant waste heat generated by various components, including batteries, motors, and power electronics. Advancements in fin design, such as the use of wavy or louvered fins, have resulted in increased heat transfer surface area and improved air-flow distribution, leading to enhanced thermal performance.

Reduced Weight and Footprint

The limited available space within electric vehicles necessitates the development of compact and lightweight air-cooled heat exchangers. Manufacturers have leveraged advanced materials and manufacturing techniques to reduce the overall weight and physical footprint of these heat exchangers, while maintaining or even enhancing their thermal management capabilities.

Enhanced Durability and Reliability

Electric vehicles operate in a wide range of environmental conditions, from extreme temperatures to vibrations and other stresses. Air-cooled heat exchangers designed for EVs must be highly durable and reliable to withstand these demanding conditions. Specialized coatings, corrosion-resistant materials, and reinforced structural designs have been implemented to ensure long-term performance and reliability.

Integrating Air-Cooled Heat Exchangers into EV Thermal Management Systems

Effective thermal management in electric vehicles requires the seamless integration of air-cooled heat exchangers with other critical systems, such as battery thermal management, motor cooling, and air conditioning. This comprehensive approach ensures that waste heat is efficiently dissipated from all the key components, optimizing overall energy utilization and performance.

Battery Thermal Management

Maintaining the optimal temperature range for lithium-ion batteries is crucial for ensuring their safety, longevity, and performance. Air-cooled heat exchangers can be strategically integrated with battery packs to effectively dissipate the heat generated during charging, discharging, and operation. This helps prevent thermal runaway, prolongs battery life, and enhances the overall driving range of the electric vehicle.

Motor Thermal Management

Electric motors in EVs generate significant amounts of heat during operation, which can adversely affect their efficiency and lifespan. Air-cooled heat exchangers can be designed to target the cooling of electric motors, ensuring that they operate within their optimal temperature range and maintain peak performance.

Air Conditioning Integration

The air conditioning system in an electric vehicle not only provides passenger comfort but also plays a crucial role in thermal management. By integrating air-cooled heat exchangers with the air conditioning system, the waste heat from the cabin and other components can be effectively dissipated, reducing the overall thermal load on the vehicle and improving energy efficiency.

Challenges and Future Developments

While the advancement of air-cooled heat exchanger technology for electric vehicles has been significant, there are still ongoing challenges and areas for further development:

System Integration and Control Algorithms

Integrating the various thermal management subsystems (battery, motor, air conditioning) into a cohesive and optimized system remains a critical challenge. Developing advanced control algorithms and sensors to manage the complex thermal interactions and ensure balanced performance is an active area of research.

Performance Optimization and Energy Efficiency

Continuously improving the thermal performance and energy efficiency of air-cooled heat exchangers is crucial for maximizing the driving range and overall efficiency of electric vehicles. Exploring advanced materials, innovative fin designs, and optimized airflow management can lead to further advancements in this area.

Cost and Manufacturing Considerations

Ensuring the cost-effectiveness and scalability of air-cooled heat exchanger solutions for electric vehicles is essential for widespread adoption. Manufacturers must balance the need for high-performance thermal management with the requirements of mass production and affordability.

Exploring Alternative Cooling Approaches

While air-cooling remains a dominant solution, the exploration of hybrid cooling techniques, such as the integration of phase change materials or liquid-cooling systems, may offer additional avenues for enhancing the thermal management capabilities of electric vehicles.

By addressing these challenges and continuing to drive innovation in air-cooled heat exchanger technology, the electric vehicle industry can unlock new levels of thermal management efficiency, safety, and overall performance, paving the way for a more sustainable and electrified future.

Conclusion

The advancements in air-cooled heat exchanger technology have been instrumental in addressing the unique thermal management challenges faced by the electric vehicle industry. From improved heat transfer efficiency and reduced weight to enhanced durability and system integration, these innovations have played a crucial role in optimizing energy utilization, prolonging component lifespans, and ensuring the overall safety and performance of electric vehicles.

As the EV market continues to evolve, the continued development and optimization of air-cooled heat exchanger solutions will be essential in driving the industry forward. By leveraging the latest materials, manufacturing techniques, and system integration strategies, the Air Cooled Heat Exchangers industry is poised to play a pivotal role in shaping the future of sustainable transportation.