Enhancing Thermal Management Capabilities with Innovative Heat Exchanger Materials

In today’s rapidly evolving industrial landscape, where energy efficiency and operational reliability are paramount, the role of air-cooled heat exchangers (ACHEs) has become increasingly crucial. These essential thermal management components are tasked with maintaining precise temperature control across a wide range of high-temperature applications, from power generation and chemical processing to semiconductor manufacturing and aerospace engineering.

As industries push the boundaries of performance and sustainability, the need for advanced heat exchanger materials has emerged as a critical area of focus. Manufacturers and engineers are continuously seeking solutions that can withstand the rigors of demanding operating environments while delivering enhanced thermal stability, corrosion resistance, and extended service life.

In this comprehensive article, we will explore the latest advancements in air-cooled heat exchanger materials, delving into the materials science, engineering innovations, and practical applications that are revolutionizing the way we approach thermal management challenges.

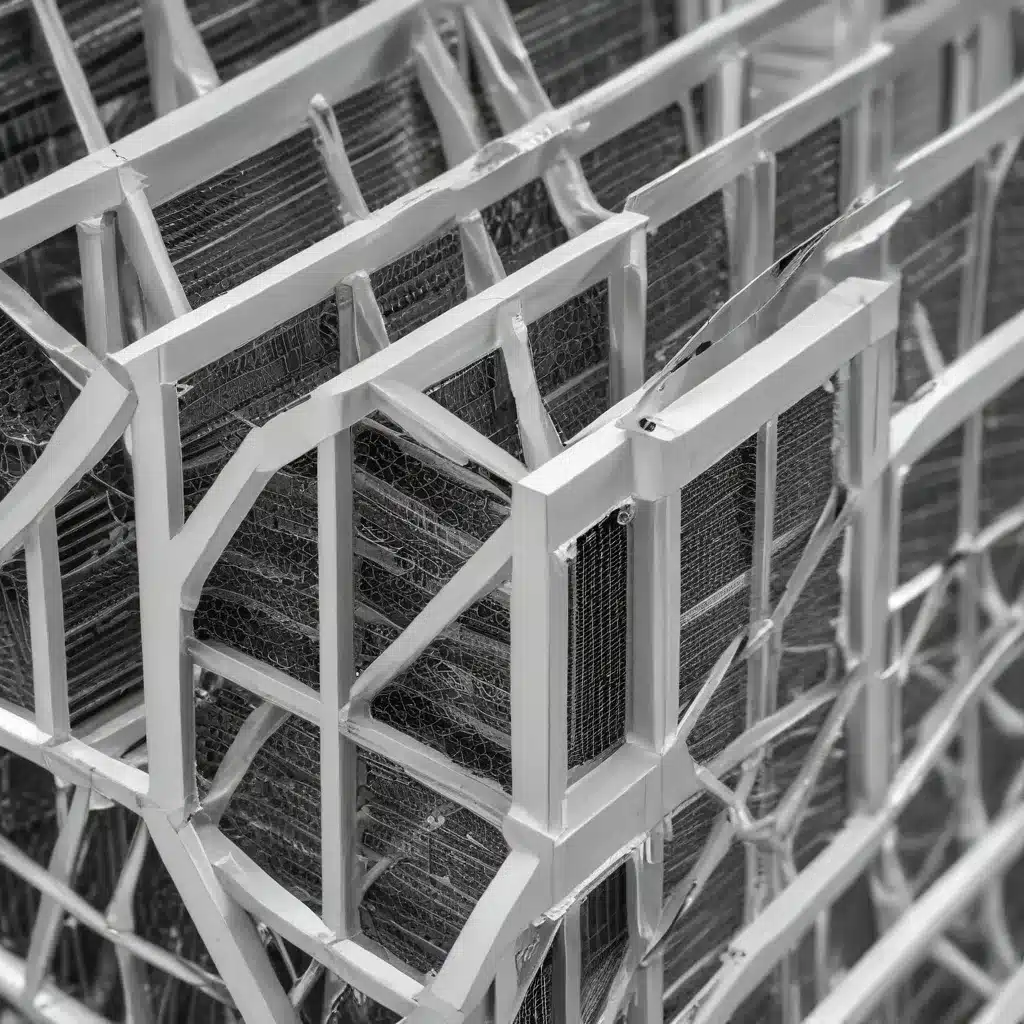

Graphite and Silicon Carbide: The New Frontier in ACHE Materials

At the forefront of this materials revolution are two remarkable substances: graphite and silicon carbide (SiC). These materials have emerged as the standout performers in the air-cooled heat exchanger domain, offering unparalleled thermal properties and exceptional durability.

Graphite, with its inherent high thermal conductivity and resistance to thermal shock, has become a go-to material for ACHE components subjected to extreme temperatures and rapid temperature fluctuations. Mersen, a leading global manufacturer, has leveraged its expertise in graphite engineering to develop advanced solutions that enhance the performance and longevity of air-cooled heat exchangers.

“Mersen’s high-purity graphite components, such as heat exchanger tubes and fins, provide superior thermal management capabilities while withstanding the harsh conditions encountered in various industrial processes,” explains Amelia Johnson, a senior process engineer at Mersen. “The thermal stability and corrosion resistance of our graphite materials are essential for ensuring the reliable operation of air-cooled heat exchangers in demanding high-temperature applications.”

Complementing the advantages of graphite, silicon carbide has emerged as a game-changer in the world of air-cooled heat exchangers. This wide-bandgap semiconductor material boasts exceptional thermal conductivity, high-temperature resilience, and outstanding corrosion resistance – properties that make it an ideal choice for ACHE applications.

The integration of SiC-based components, such as heat exchanger surfaces and coatings, has opened up new frontiers in thermal management optimization. By leveraging the unique physical and chemical properties of silicon carbide, manufacturers can now design ACHEs that operate at higher temperatures, exhibit enhanced heat transfer efficiency, and demonstrate extended service life.

Conquering Thermal Stability Challenges in High-Temperature Environments

One of the primary challenges faced by air-cooled heat exchangers is the ability to maintain thermal stability and performance consistency in high-temperature applications. Exposure to extreme temperatures, thermal cycling, and corrosive environments can lead to material degradation, reduced heat transfer efficiency, and ultimately, premature equipment failure.

Mersen’s innovative approach to addressing these challenges involves the strategic use of high-purity graphite and SiC-coated materials. These advanced materials have demonstrated exceptional resistance to oxidation, erosion, and thermal fatigue, ensuring that air-cooled heat exchangers maintain their structural integrity and thermal management capabilities over extended periods of operation.

“The key to overcoming thermal stability challenges lies in the selection of the right materials and the precision engineering of ACHE components,” states Amelia Johnson. “By leveraging the latest advancements in graphite and silicon carbide technologies, we can now design heat exchangers that are more resilient to the harsh conditions encountered in high-temperature industrial settings.”

Enhancing Thermal Management Efficiency through Innovative Materials

Alongside thermal stability, the pursuit of improved thermal management efficiency has been a driving force behind the development of advanced air-cooled heat exchanger materials. As industries strive to optimize energy consumption and reduce environmental impact, the ability to enhance heat transfer performance has become increasingly crucial.

Graphite’s exceptional thermal conductivity and tailorable properties have made it a preferred material for ACHE components, enabling engineers to design heat exchangers that effectively transfer heat from one medium to another. The use of high-purity graphite in critical heat exchanger elements, such as fins and tubes, has resulted in enhanced heat transfer rates and improved overall system efficiency.

Furthermore, the integration of silicon carbide has revolutionized the thermal management capabilities of air-cooled heat exchangers. SiC’s superior thermal conductivity, combined with its resistance to thermal fatigue and oxidation, has allowed for the development of heat exchangers that can operate at higher temperatures while maintaining consistent performance.

“The integration of SiC-based materials, such as CVD Silicon Carbide coatings, has been a game-changer in the air-cooled heat exchanger industry,” explains Amelia Johnson. “These advanced coatings not only enhance the thermal conductivity of heat exchanger surfaces but also provide exceptional protection against high-temperature corrosion, ensuring long-term reliability and efficiency.”

Addressing Maintenance and Longevity Challenges with Innovative Materials

The longevity and maintenance requirements of air-cooled heat exchangers have always been a critical consideration for industrial operators. Prolonged exposure to harsh environments, thermal cycling, and corrosive substances can lead to material degradation, increased maintenance costs, and unexpected downtime.

Mersen’s focus on developing advanced materials for air-cooled heat exchangers has directly addressed these challenges, offering solutions that extend service life and reduce maintenance burdens.

The use of high-purity graphite and SiC-coated components in ACHEs has demonstrated superior resistance to erosion, corrosion, and thermal fatigue. These materials maintain their structural integrity and performance characteristics for extended periods, reducing the need for frequent replacements or costly repairs.

“The durability of our graphite and SiC-based heat exchanger materials has been a game-changer for our customers,” says Amelia Johnson. “By minimizing the maintenance requirements and extending the service life of air-cooled heat exchangers, we are helping industrial operators achieve greater cost savings and operational efficiency.”

Tailoring Materials for Specific Application Needs

As the air-cooled heat exchanger industry continues to evolve, the need for customized solutions has become increasingly apparent. Different industrial sectors and applications often have unique thermal management requirements, necessitating the development of specialized materials and designs.

Mersen’s expertise in materials science and engineering has enabled the company to offer tailored solutions for a wide range of ACHE applications. Whether it’s the high-purity graphite components required for semiconductor manufacturing or the SiC-coated heat exchanger surfaces needed in the chemical processing industry, Mersen’s team of experts can provide customized materials and configurations to meet the precise needs of their clients.

“By working closely with our customers and understanding their specific application requirements, we are able to develop air-cooled heat exchanger solutions that optimize thermal performance, enhance durability, and minimize maintenance,” explains Amelia Johnson. “Our versatile materials portfolio, combined with our in-depth knowledge of industrial processes, allows us to engineer ACHEs that deliver unparalleled value to our clients.”

Innovations in Epitaxial Processes: The Role of Advanced ACHE Materials

The semiconductor industry, with its relentless pursuit of performance and efficiency, has emerged as a prime beneficiary of the advancements in air-cooled heat exchanger materials. Epitaxial processes, which involve the precise deposition of crystalline layers onto a substrate, are critical in semiconductor manufacturing and rely heavily on the thermal management capabilities of ACHEs.

Mersen’s high-purity graphite and SiC-based materials have played a pivotal role in enhancing the precision and consistency of epitaxial processes. These advanced materials, used in components such as graphite susceptors and wafer carriers, have enabled tighter temperature control, improved thermal stability, and reduced contamination risks – all of which are essential for producing high-quality semiconductor devices.

“The epitaxial process is extremely sensitive to temperature fluctuations and impurities, making the choice of ACHE materials a crucial factor in achieving optimal results,” says Amelia Johnson. “Mersen’s expertise in developing graphite and SiC-based solutions tailored for semiconductor manufacturing has been instrumental in pushing the boundaries of epitaxial technology.”

The Future of Air-Cooled Heat Exchangers: Embracing Sustainability and Efficiency

As the global industrial landscape continues to evolve, the demand for more sustainable and energy-efficient thermal management solutions has become increasingly pressing. Mersen’s commitment to innovation and materials science has positioned the company at the forefront of this transformative shift, with a focus on developing air-cooled heat exchanger materials that not only perform exceptionally but also contribute to a greener future.

The integration of advanced graphite and silicon carbide technologies in ACHEs has yielded remarkable improvements in energy efficiency. These materials’ superior thermal properties have enabled the design of heat exchangers that optimize heat transfer, minimize energy consumption, and reduce the environmental footprint of various industrial operations.

Furthermore, Mersen’s ongoing research and development efforts have explored the potential of emerging materials, such as hybrid composites and nanomaterials, to further enhance the sustainability and performance of air-cooled heat exchangers. These innovations hold the promise of even more efficient and environmentally responsible thermal management solutions for the future.

“As we look ahead, Mersen is committed to spearheading the development of air-cooled heat exchanger materials that not only push the boundaries of thermal management capabilities but also contribute to a more sustainable industrial ecosystem,” affirms Amelia Johnson. “By leveraging our expertise in materials science and engineering, we aim to empower our clients to achieve their environmental goals and operational objectives simultaneously.”

Conclusion: Embracing the Future of Air-Cooled Heat Exchanger Materials

The advancements in air-cooled heat exchanger materials, spearheaded by the exceptional properties of graphite and silicon carbide, have ushered in a new era of thermal management optimization. These innovative materials have enabled the design of ACHEs that can withstand the rigors of high-temperature environments, enhance overall system efficiency, and deliver extended service life – all while contributing to a more sustainable industrial landscape.

As industries continue to demand higher performance, increased reliability, and greater sustainability, the role of advanced ACHE materials will only continue to grow. Mersen’s commitment to materials science research and engineering expertise positions the company as a trailblazer in this dynamic field, empowering its clients to navigate the challenges of the modern industrial world with confidence and efficiency.

By embracing the transformative potential of graphite, silicon carbide, and other cutting-edge materials, the air-cooled heat exchanger industry is poised to unlock new frontiers of thermal management, paving the way for a future where energy efficiency, operational reliability, and environmental responsibility converge seamlessly.

Visit https://www.aircooledheatexchangers.net/ to explore Mersen’s comprehensive range of air-cooled heat exchanger solutions and discover how their innovative materials can elevate your thermal management capabilities.