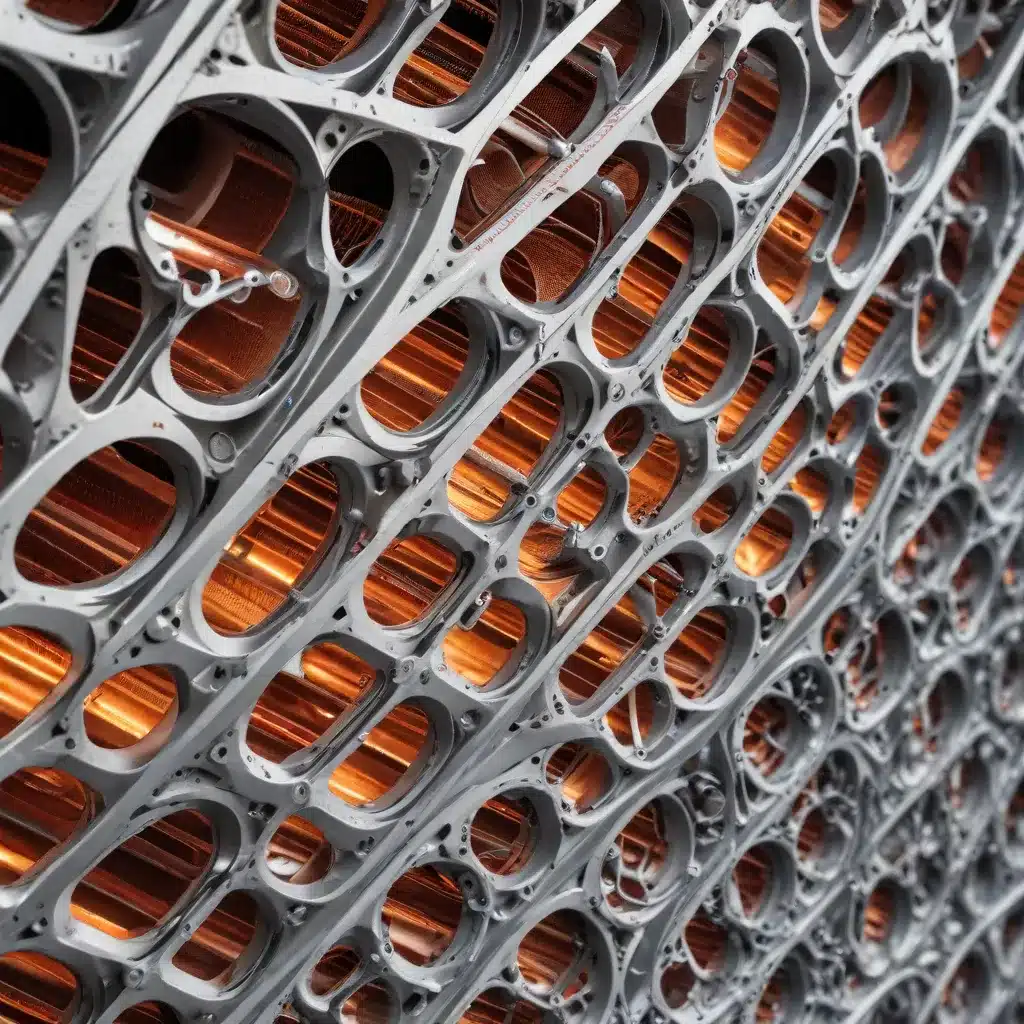

The Importance of Material Selection in Air-Cooled Heat Exchanger Design

Air-cooled heat exchangers are an integral part of numerous industrial processes, playing a critical role in heat transfer, energy efficiency, and process optimization. The performance and reliability of these systems are heavily influenced by the materials used in their construction. As industries continue to demand greater efficiency, thermal management, and cost-effectiveness, the development of advanced heat exchanger materials has become a focal point of research and innovation.

This article delves into the latest advancements in air-cooled heat exchanger materials, exploring how new and improved materials can enhance thermal conductivity, mechanical properties, and overall system performance. By understanding the capabilities of emerging materials, design engineers can make informed decisions that drive the evolution of air-cooled heat exchangers across a wide range of applications.

Janus Textiles: Unidirectional Moisture Management for Improved Thermal Comfort

One of the key challenges in air-cooled heat exchanger design is ensuring efficient heat dissipation while maintaining user comfort, especially in personal protective equipment (PPE) applications. Traditional isolation gowns and protective layers often have low permeability, trapping moisture and heat within the clothing microclimate and leading to thermal discomfort for the wearer.

Janus textiles, with their unique ability to transport moisture unidirectionally, present a promising solution to this problem. These materials, which can be produced using electrospinning techniques, feature a gradient of hydrophilicity across their thickness, allowing sweat to be wicked away from the skin and expelled to the outer layer of the fabric. This not only enhances evaporative cooling but also helps maintain a drier, more comfortable microclimate within the PPE system.

By incorporating Janus textiles into the design of air-cooled heat exchanger protective layers, engineers can leverage the superior moisture management properties to improve thermal comfort and user experience, without compromising the critical barrier function required for infection control.

Infrared-Transparent, Visible-Opaque (ITVO) Fabrics: Optimizing Radiative Heat Transfer

Another area of advancement in air-cooled heat exchanger materials is the development of infrared-transparent, visible-opaque (ITVO) fabrics. These specialized materials are designed to selectively transmit infrared (IR) radiation from the human body while reflecting or scattering visible light, effectively enhancing radiative heat loss.

ITVO fabrics, often made from nanoporous polyethylene (nanoPE) or similar high-IR-transmittance polymers, can be strategically positioned as the outermost layer of air-cooled heat exchanger garments. This configuration allows the wearer’s body heat to be efficiently radiated towards the cooler surroundings, providing an additional cooling mechanism to complement the air-based heat transfer.

Importantly, the vapor permeability and water-repellent properties of ITVO fabrics also contribute to improved moisture management, further enhancing the overall thermal comfort of the PPE system.

Advancements in Phase Change Materials (PCMs) for Enhanced Cooling Capacity

Phase change materials (PCMs) have long been a popular choice for personal cooling applications, leveraging their ability to absorb and release latent heat during phase transitions. Recent developments in PCM encapsulation and integration techniques have led to significant improvements in their performance and wearability when applied in air-cooled heat exchanger systems.

One notable advancement is the use of continuous fillers, such as graphene, carbon nanotubes, or graphene aerogels, to enhance the thermal conductivity of PCM-containing composites. By creating a highly conductive network within the PCM matrix, these fillers help to improve heat transfer, reducing the risk of localized overcooling and ensuring a more uniform cooling effect across the wearer’s body.

Additionally, the emergence of core-sheath PCM fibers, produced through coaxial electrospinning, has enabled the integration of PCMs into textiles without compromising the fabric’s flexibility, breathability, or overall comfort. The sheath material serves to encapsulate the PCM core, preventing leakage while maintaining the desired thermal and moisture management properties.

These innovations in PCM materials and integration techniques have expanded the potential of air-cooled heat exchanger systems to provide efficient, long-lasting, and comfortable personal cooling solutions.

Thermoelectric (TE) Cooling: Stable and Adjustable Personal Thermal Management

While passive cooling methods like PCMs offer simplicity and portability, active cooling systems based on thermoelectric (TE) technology can provide more stable and customizable cooling performance for air-cooled heat exchanger applications.

TE cooling devices leverage the Peltier effect, where the application of an electric current results in a temperature difference across the device. By carefully designing the TE module and optimizing the heat sink configuration, engineers can deliver targeted cooling to specific areas of the body, while maintaining a comfortable overall microclimate.

Recent advancements in TE materials, such as the use of rigid inorganic TE pillars embedded in flexible elastomer sheets, have helped to improve the mechanical properties and wearability of TE-based cooling systems. Additionally, the incorporation of air-based heat sinks and forced convection can further enhance the overall cooling efficiency of TE-powered air-cooled heat exchangers.

The adjustability and responsiveness of TE cooling make it a compelling choice for applications where precise thermal management is critical, such as in specialized PPE or industrial workwear.

Thermal Conductive Textiles: Improving Heat Distribution and Dissipation

To complement the cooling capabilities of advanced materials like PCMs and TE devices, the development of highly thermally conductive textiles has become another area of focus in air-cooled heat exchanger design.

Materials such as carbon nanotubes (CNTs), graphene, and boron nitride (BN) possess exceptional thermal conductivities, which can be leveraged to create textile-based heat transfer media. By integrating these conductive materials into fabrics or yarn structures, engineers can facilitate the distribution of cooling effects across a larger surface area, ensuring more uniform temperature regulation and improved heat dissipation.

Innovative fabrication techniques, such as wet spinning, dry spinning, and electrospinning, have enabled the production of thermally conductive textile structures that maintain desirable mechanical properties, flexibility, and breathability. These advances have expanded the possibilities for integrating thermally conductive textiles into air-cooled heat exchanger systems, enhancing their overall thermal management capabilities.

Optimizing Material Compatibility and System Integration

While the individual advancements in materials like Janus textiles, ITVO fabrics, PCMs, TE devices, and thermally conductive textiles are significant, the true potential of air-cooled heat exchanger systems lies in the seamless integration of these complementary technologies.

Design engineers must carefully consider the compatibility, synergies, and trade-offs between different materials and cooling strategies to create cohesive, high-performance air-cooled heat exchanger systems. This may involve balancing factors such as thermal conductivity, mechanical durability, weight, flexibility, and breathability to ensure optimal heat transfer, user comfort, and system robustness.

By adopting a holistic, system-level approach to material selection and integration, air-cooled heat exchanger designers can unlock new levels of efficiency, versatility, and user-centered performance. This comprehensive understanding of advanced materials and their synergistic application is crucial for driving the next generation of air-cooled heat exchanger technologies.

Conclusion: Embracing the Future of Air-Cooled Heat Exchanger Materials

The advancements in air-cooled heat exchanger materials outlined in this article underscore the dynamic and ever-evolving nature of this field. By embracing the latest innovations in Janus textiles, ITVO fabrics, PCMs, TE cooling, and thermally conductive textiles, design engineers can unlock new levels of efficiency, thermal management, and user comfort in a wide range of industrial, commercial, and personal applications.

As industries continue to demand greater performance, reliability, and sustainability from their air-cooled heat exchanger systems, the strategic selection and integration of advanced materials will be paramount. By staying at the forefront of material science and engineering, air-cooled heat exchanger professionals can position their organizations for long-term success and contribute to the ongoing transformation of this critical technology.

To learn more about the latest advancements in air-cooled heat exchanger materials and their practical applications, visit https://www.aircooledheatexchangers.net/. Our team of experts is dedicated to providing the most up-to-date information and insights to help you navigate the evolving landscape of this dynamic field.