Exploring the Latest Innovations in Combating Corrosion in Air-Cooled Heat Exchangers

Air-cooled heat exchangers are essential components in a wide range of industrial processes, from power generation and petrochemical refineries to HVAC systems and data centers. As these critical pieces of equipment operate in increasingly demanding environments, the need for enhanced corrosion resistance has become paramount. Fortunately, the industry has seen a wave of advancements in air-cooled heat exchanger materials that are helping to combat the detrimental effects of corrosion.

In this comprehensive article, we delve into the latest developments in air-cooled heat exchanger materials, exploring how these innovations are improving corrosion resistance and delivering tangible benefits to industrial operations. From novel coating technologies to advanced alloy compositions, we’ll examine the key trends and provide practical insights to help you maximize the performance and longevity of your air-cooled heat exchangers.

The Corrosion Challenge in Air-Cooled Heat Exchangers

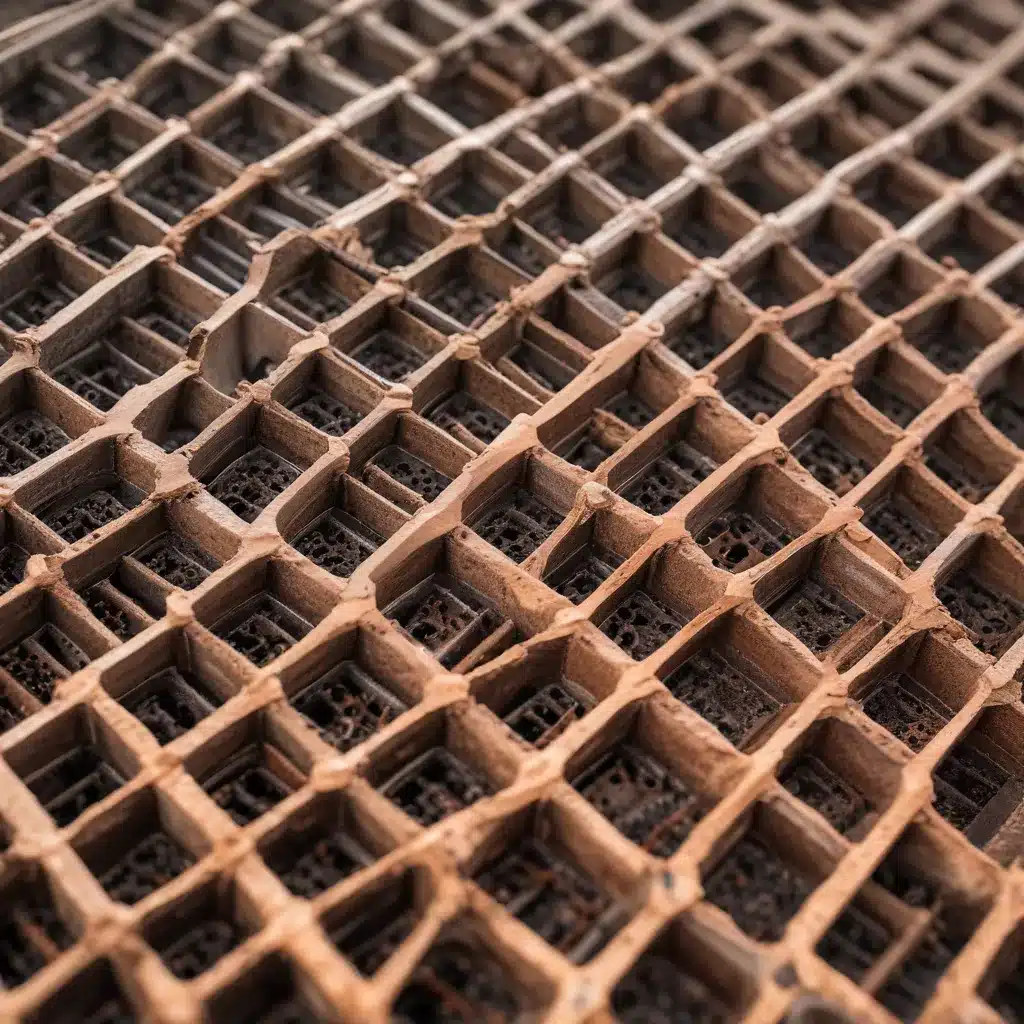

Air-cooled heat exchangers face a unique set of corrosion challenges due to their exposure to a wide range of environmental factors, including temperature fluctuations, humidity, and airborne contaminants. Over time, these elements can take a toll on the materials used in the construction of air-cooled heat exchangers, leading to performance degradation, reduced efficiency, and even catastrophic failures.

Corrosion in air-cooled heat exchangers can manifest in various forms, such as:

- General corrosion: A uniform thinning of the metal surface, which can compromise the structural integrity of the heat exchanger.

- Pitting corrosion: The formation of localized cavities or holes in the metal, which can lead to leaks and reduced heat transfer.

- Galvanic corrosion: Occurs when two dissimilar metals are in contact, creating an electrochemical reaction that accelerates the corrosion of the less noble metal.

- Stress corrosion cracking: The combined effects of corrosion and mechanical stress, resulting in the development of cracks that can propagate and cause component failure.

Addressing these corrosion challenges is crucial for maintaining the reliable operation of air-cooled heat exchangers, minimizing downtime, and ensuring the safety of personnel and the surrounding environment.

Innovative Materials for Improved Corrosion Resistance

To combat the persistent issue of corrosion in air-cooled heat exchangers, manufacturers and materials scientists have been working diligently to develop and refine a range of innovative solutions. Here are some of the key advancements in air-cooled heat exchanger materials that are enhancing corrosion resistance:

Corrosion-Resistant Alloys

One of the most significant developments in air-cooled heat exchanger materials has been the introduction of highly corrosion-resistant alloys. These advanced alloys are engineered to provide superior protection against the various forms of corrosion that can plague traditional materials, such as carbon steel or copper-based alloys.

Stainless Steel Alloys:

Stainless steel alloys, particularly those with higher chromium content, have become increasingly popular in air-cooled heat exchanger applications. The chromium in these alloys forms a passive, self-healing oxide layer that provides excellent protection against general corrosion, pitting, and crevice corrosion. Examples of high-performance stainless steel alloys include 316L, 317L, and duplex stainless steels.

Nickel-Based Alloys:

Nickel-based alloys, such as Inconel and Hastelloy, have also gained traction in air-cooled heat exchanger design due to their exceptional resistance to a wide range of corrosive environments. These alloys are particularly well-suited for applications involving high temperatures, aggressive chemicals, or seawater exposure, making them ideal for offshore and coastal facilities.

Aluminum Alloys:

Aluminum alloys have long been a popular choice for air-cooled heat exchangers due to their lightweight, high thermal conductivity, and relatively low cost. Recent advancements in aluminum alloy compositions, such as the incorporation of magnesium, silicon, and other alloying elements, have significantly improved their corrosion resistance, making them a more viable option for challenging environments.

The selection of the appropriate corrosion-resistant alloy for an air-cooled heat exchanger depends on factors such as the operating conditions, exposure to chemicals or contaminants, and the required mechanical properties. Careful evaluation of these factors, along with consultation with materials experts, is essential to ensure the optimal performance and longevity of the heat exchanger.

Coatings and Surface Treatments

In addition to advancements in alloy compositions, the use of protective coatings and surface treatments has emerged as a powerful strategy for enhancing the corrosion resistance of air-cooled heat exchangers. These specialized coatings and treatments can be applied to a wide range of underlying materials, providing an additional layer of defense against corrosion.

Polymer-Based Coatings:

Polymer-based coatings, such as epoxy, polyurethane, and fluoropolymer-based systems, have gained popularity for their ability to create a physical barrier against corrosive elements. These coatings can be customized to provide enhanced resistance to specific corrosive agents, as well as improved thermal management properties.

Metallic Coatings:

Metallic coatings, including zinc, aluminum, and chromium-based systems, offer exceptional protection against general corrosion, pitting, and galvanic corrosion. These coatings can be applied through a variety of techniques, such as electroplating, hot-dip galvanizing, or thermal spraying, to suit the specific requirements of the air-cooled heat exchanger.

Ceramic and Enamel Coatings:

Ceramic and enamel-based coatings have also demonstrated their effectiveness in combating corrosion in air-cooled heat exchangers. These coatings provide a highly durable and chemically resistant surface that can withstand high temperatures, abrasion, and exposure to aggressive media.

Surface Treatments:

Beyond coatings, innovative surface treatments, such as passivation, anodizing, and shot peening, can also enhance the corrosion resistance of air-cooled heat exchanger materials. These treatments modify the surface properties of the metal, creating a more stable and protective oxide layer or introducing compressive stresses that can inhibit the initiation and propagation of corrosion.

The selection of the appropriate coating or surface treatment for an air-cooled heat exchanger depends on factors such as the operating environment, the underlying material, and the required level of corrosion protection. Consulting with materials and coatings experts is crucial to ensure the optimal solution for your specific application.

Improved Maintenance and Cleaning Practices

While advancements in materials and coatings play a vital role in mitigating corrosion in air-cooled heat exchangers, proper maintenance and cleaning practices are also essential for maintaining their long-term performance and reliability.

Regular inspection and cleaning of air-cooled heat exchangers can help to identify and address corrosion issues before they escalate into more serious problems. Various cleaning methods, such as mechanical cleaning, chemical cleaning, and ultrasonic cleaning, can be employed to remove deposits, scale, and other contaminants that can accelerate corrosion.

Moreover, the integration of digital monitoring and predictive maintenance technologies can provide valuable insights into the condition of air-cooled heat exchangers, allowing operators to proactively address corrosion concerns before they impact system performance. By leveraging these advanced tools and implementing robust maintenance programs, industrial facilities can maximize the lifespan and efficiency of their air-cooled heat exchangers.

Case Studies: Improved Corrosion Resistance in Action

To illustrate the real-world benefits of the advancements in air-cooled heat exchanger materials, let’s examine a few case studies:

Case Study 1: Refinery Upgrades to Corrosion-Resistant Alloys

A refinery that was experiencing extensive pitting and general corrosion in its air-cooled heat exchangers decided to upgrade to high-performance stainless steel alloys, specifically 316L and 317L grades. The new air-cooled heat exchangers demonstrated significantly improved resistance to the corrosive environment, which included exposure to acidic and chloride-rich process streams. As a result, the refinery was able to extend the service life of the heat exchangers, reduce costly maintenance and downtime, and improve the overall reliability of its cooling systems.

Case Study 2: Offshore Platform Selects Nickel-Based Alloys

An offshore oil and gas platform located in a highly corrosive, saltwater-rich environment faced ongoing challenges with the corrosion of its air-cooled heat exchangers. After evaluating various material options, the platform operators decided to replace the existing heat exchangers with Inconel alloy units. The superior corrosion resistance of the Inconel alloy enabled the heat exchangers to withstand the harsh marine environment, minimizing the need for frequent replacements and reducing the risk of costly equipment failures.

Case Study 3: Aluminum Alloy Upgrades Improve HVAC Performance

A commercial HVAC facility experienced persistent issues with the corrosion of its air-cooled heat exchangers, leading to reduced efficiency and increased maintenance requirements. By upgrading to aluminum alloys with enhanced corrosion resistance, the facility was able to significantly improve the longevity and performance of its cooling systems. The new air-cooled heat exchangers not only demonstrated improved resistance to corrosion but also delivered increased heat transfer capabilities, optimizing the overall energy efficiency of the HVAC system.

These case studies highlight the tangible benefits that advancements in air-cooled heat exchanger materials can deliver, including extended equipment life, reduced maintenance costs, and enhanced system reliability – all of which contribute to the overall operational efficiency and profitability of industrial facilities.

Conclusion: Embracing the Future of Corrosion-Resistant Air-Cooled Heat Exchangers

The ongoing evolution of air-cooled heat exchanger materials has been a game-changer for industrial operations, providing a critical solution to the persistent challenge of corrosion. By leveraging innovative alloys, advanced coatings, and thoughtful maintenance practices, industrial facilities can now enjoy improved performance, extended equipment life, and greater energy efficiency – all while mitigating the risks and costs associated with corrosion.

As the demand for reliable and corrosion-resistant air-cooled heat exchangers continues to grow, it is essential for industrial operators to stay informed about the latest advancements in this field. By partnering with materials experts and heat exchanger manufacturers, you can ensure that your facility is equipped with the most robust and durable air-cooled heat exchangers, capable of withstanding the rigors of your operating environment.

To learn more about the latest developments in air-cooled heat exchanger materials and how they can benefit your operation, be sure to visit https://www.aircooledheatexchangers.net/. Our team of industry experts is dedicated to providing the insights and resources you need to optimize the performance and longevity of your critical heat transfer equipment.