Optimizing Air-Cooled Heat Exchanger Performance through Enhanced Modeling

As the seasoned expert in the field of air-cooled heat exchangers, I am thrilled to share insights on the advancements in modeling and simulation of these critical thermal management systems. Air-cooled heat exchangers play a pivotal role across numerous industries, from power generation and petrochemical processing to HVAC and automotive applications. Understanding the underlying heat transfer mechanisms and leveraging sophisticated modeling techniques is crucial for designing efficient, reliable, and high-performing air-cooled heat exchangers.

Unlocking the Potential of Computational Fluid Dynamics (CFD)

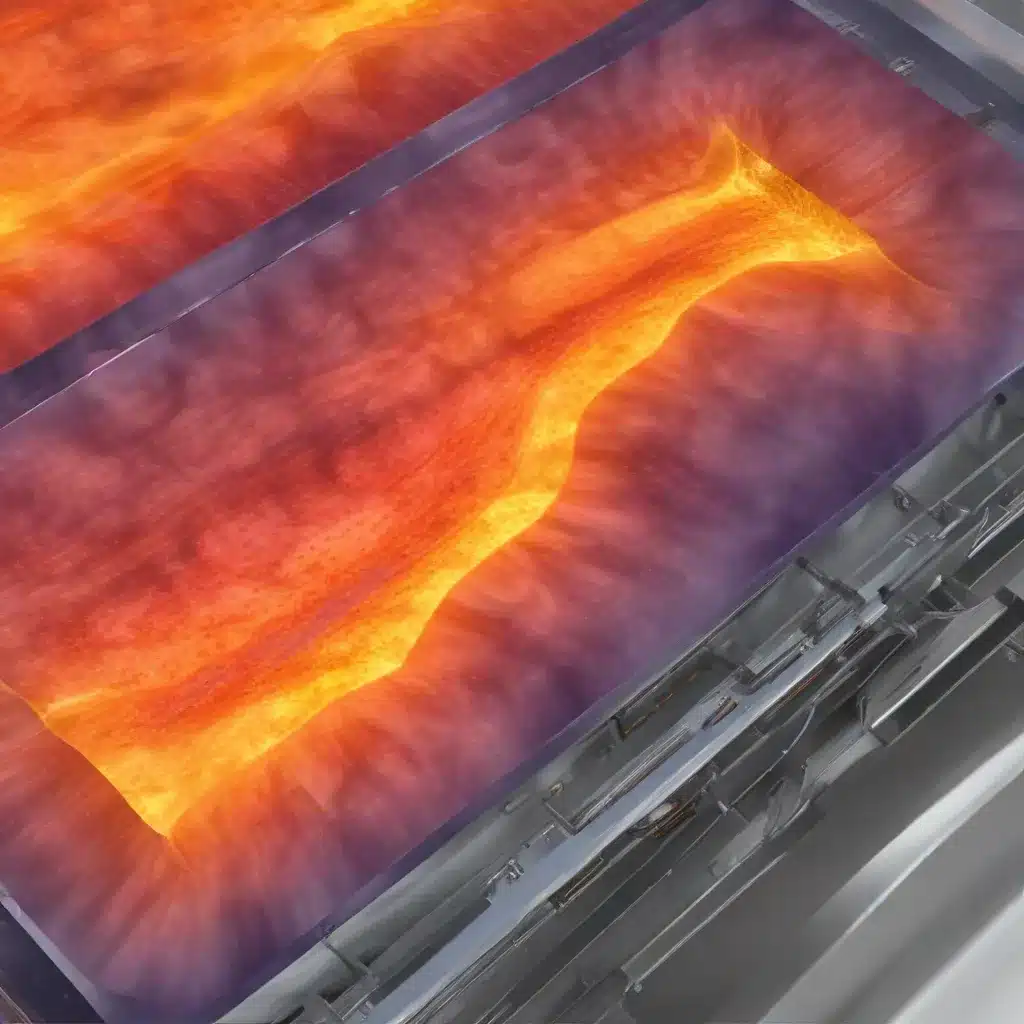

One of the most significant advancements in the modeling and simulation of air-cooled heat transfer processes has been the widespread adoption of Computational Fluid Dynamics (CFD) technologies. CFD tools allow engineers to accurately simulate the intricate fluid flow patterns and heat transfer characteristics within air-cooled heat exchangers, providing invaluable insights that were previously difficult to obtain through experimental means alone.

By integrating CFD simulations into the design process, engineers can explore a wider range of design parameters, optimize airflow patterns, and predict the thermal performance of air-cooled heat exchangers with remarkable accuracy. This capability has been particularly beneficial for industries where operational efficiency, compactness, and weight are critical considerations, such as in the automotive and aerospace sectors.

Furthermore, advancements in computational power and the development of user-friendly CFD software have made these simulation tools more accessible to a broader range of heat exchanger designers and researchers. This democratization of CFD has enabled more comprehensive design optimization, leading to significant improvements in air-cooled heat exchanger performance and energy efficiency.

Advancing Multiphysics Modeling Approaches

Another key development in the field of air-cooled heat exchanger modeling has been the incorporation of multiphysics approaches. These advanced techniques combine the analysis of fluid dynamics, heat transfer, structural mechanics, and even electrochemical processes within a unified computational framework.

By considering the complex interplay between multiple physical phenomena, multiphysics modeling enables a more holistic understanding of air-cooled heat exchanger behavior. For example, integrating structural analysis with thermal simulations can help predict the impact of thermal stresses on the heat exchanger’s mechanical integrity, informing design decisions and maintenance strategies.

Similarly, the inclusion of electrochemical processes in the modeling of air-cooled heat exchangers used in fuel cell or battery thermal management systems can provide valuable insights into the effects of corrosion, fouling, and other degradation mechanisms. This comprehensive approach to modeling helps engineers develop more robust and reliable air-cooled heat exchanger designs that can withstand the rigors of real-world operating conditions.

Unlocking the Potential of Machine Learning and Data-Driven Modeling

The emergence of machine learning and data-driven modeling techniques has further expanded the capabilities of air-cooled heat exchanger simulation and optimization. By leveraging vast datasets, either from experimental studies or detailed CFD simulations, researchers and engineers can develop predictive models that capture the complex relationships between design parameters, operating conditions, and thermal performance.

These data-driven models, often in the form of neural networks or surrogate models, can significantly accelerate the design optimization process by providing fast and accurate predictions without the need for computationally intensive simulations. This approach is particularly valuable when exploring multidimensional design spaces or when dealing with complex geometries and operating scenarios that would be challenging to model using traditional analytical or numerical methods.

Furthermore, the integration of machine learning algorithms with real-time sensor data can enable adaptive control and predictive maintenance strategies for air-cooled heat exchangers. By continuously monitoring the system’s performance and identifying early signs of degradation, operators can optimize operating parameters, schedule preventive maintenance, and maximize the overall efficiency and reliability of the heat exchanger.

Bridging the Gap between Modeling and Real-World Applications

While the advancements in modeling and simulation have been remarkable, it is essential to recognize the importance of bridging the gap between the virtual world and real-world air-cooled heat exchanger applications. Validated models and simulation tools are crucial, but they must be complemented by thorough experimental validation, field testing, and ongoing performance monitoring.

By combining the insights gained from advanced modeling techniques with empirical data and practical experience, engineers can develop more accurate and reliable predictive models. This iterative process of model refinement and validation ensures that the design, optimization, and maintenance of air-cooled heat exchangers are grounded in a deep understanding of the underlying physical phenomena and the unique operational challenges faced in various industries.

As the industry continues to push the boundaries of air-cooled heat exchanger performance, the synergistic integration of modeling, simulation, and real-world validation will be essential for driving innovation, improving energy efficiency, and maintaining the reliability of these critical thermal management systems.

Conclusion: Embracing the Future of Air-Cooled Heat Exchanger Design

In the ever-evolving landscape of air-cooled heat exchanger technology, the advancements in modeling and simulation have been truly transformative. From the power of Computational Fluid Dynamics to the integration of multiphysics approaches and the embrace of machine learning, the thermal engineering community has made remarkable strides in unlocking the full potential of these essential heat transfer systems.

By harnessing the capabilities of these cutting-edge modeling techniques, engineers and researchers can design more efficient, reliable, and responsive air-cooled heat exchangers that meet the stringent demands of modern industries. As we continue to push the boundaries of what is possible, the future of air-cooled heat exchanger design holds endless possibilities, paving the way for a more sustainable and innovative future.

To stay up-to-date with the latest developments in air-cooled heat exchanger technology, I encourage you to visit the Air Cooled Heat Exchangers blog, where we dive deep into the cutting-edge advancements, practical insights, and industry-leading expertise that are shaping the future of this critical field.