In the ever-evolving world of industrial equipment and processes, the performance and efficiency of air-cooled heat exchangers have become increasingly crucial. As industries strive for improved thermal management, reduced energy consumption, and enhanced operational longevity, the materials and coatings used in these critical components have undergone remarkable advancements. This article delves into the latest developments in materials and coatings that are revolutionizing the air-cooled heat exchanger landscape.

Innovative Heat Exchanger Materials

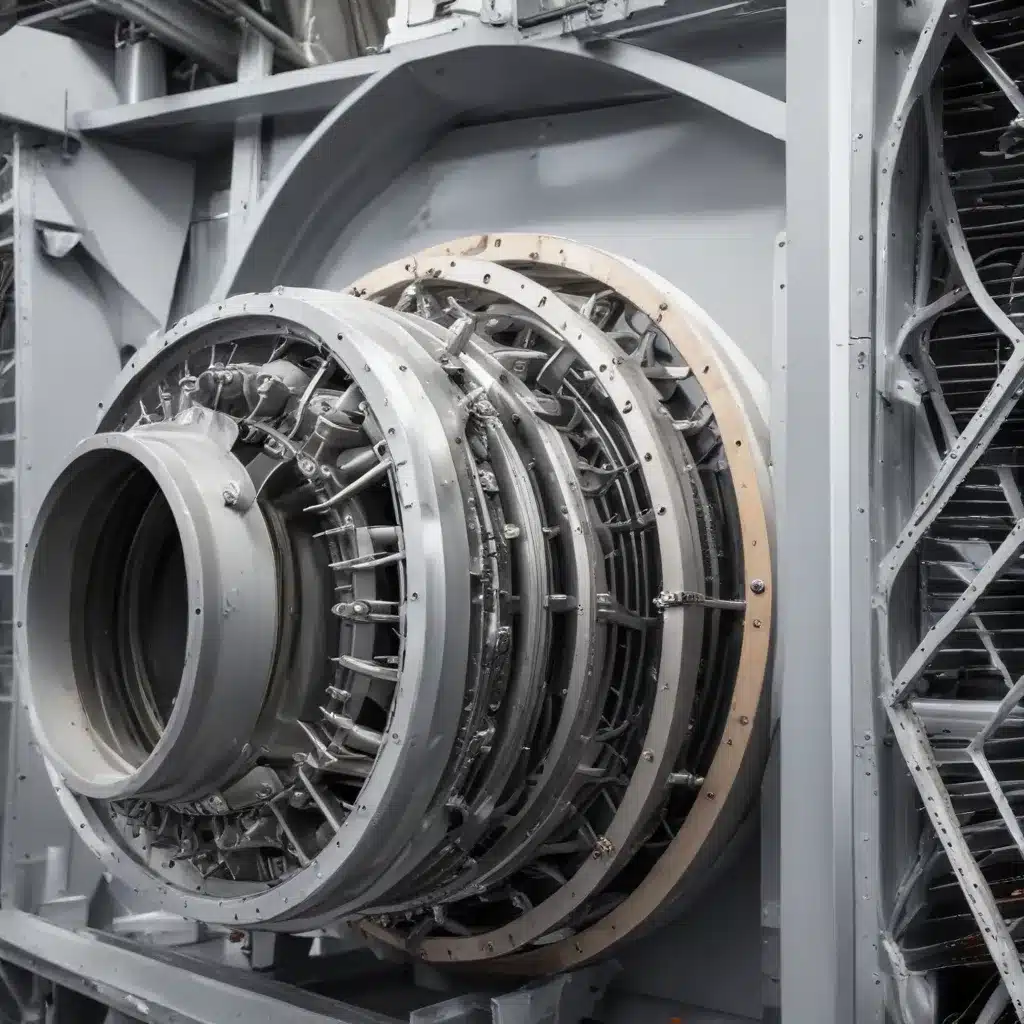

The core of an air-cooled heat exchanger is its heat transfer surface, which plays a pivotal role in its overall performance. Traditionally, materials such as copper, aluminum, and stainless steel have been the go-to choices for heat exchanger construction. However, the quest for enhanced efficiency and durability has led to the emergence of new materials that offer distinct advantages.

Copper-Aluminum Composite Materials

One of the notable advancements in heat exchanger materials is the introduction of copper-aluminum composite materials. These innovative composites leverage the superior thermal conductivity of copper with the lightweight and corrosion-resistance of aluminum, creating a synergistic solution. Research has shown that copper-aluminum composites can achieve up to a 20% improvement in heat transfer performance compared to traditional aluminum alloys, while also exhibiting enhanced mechanical strength and corrosion resistance.

Titanium and Titanium Alloys

Titanium and its alloys have also gained traction in the air-cooled heat exchanger market, particularly in applications where resistance to corrosion and high-temperature environments is paramount. Titanium’s inherent properties, such as high strength-to-weight ratio, exceptional corrosion resistance, and thermal stability, make it an attractive choice for heat exchangers in industries like chemical processing, power generation, and offshore oil and gas operations.

Ceramic Matrix Composites (CMCs)

Ceramic matrix composites (CMCs) have emerged as a novel class of materials for air-cooled heat exchangers, offering exceptional thermal and mechanical properties. These composites, which typically combine ceramic materials with reinforcing fibers, can withstand higher temperatures, resist corrosion, and maintain structural integrity even in the most demanding operating conditions. Research has demonstrated that CMCs can improve heat transfer efficiency by up to 15% compared to traditional metallic heat exchangers.

Additive Manufacturing and Customized Designs

The advent of advanced manufacturing techniques, such as additive manufacturing (AM) or 3D printing, has revolutionized the way air-cooled heat exchangers are designed and fabricated. AM allows for the creation of complex, customized heat exchanger geometries and internal flow paths, optimizing heat transfer and reducing pressure drops. This technology enables the development of highly efficient, tailored heat exchanger solutions for specific applications and operating environments.

Innovative Coatings and Surface Treatments

Coatings and surface treatments play a crucial role in enhancing the performance and longevity of air-cooled heat exchangers. These advancements go beyond the traditional surface finishes, offering a wide range of benefits, from improved heat transfer to enhanced durability and corrosion resistance.

Hydrophilic and Hydrophobic Coatings

One of the significant advancements in heat exchanger coatings is the development of hydrophilic and hydrophobic surfaces. Hydrophilic coatings, such as those based on titanium dioxide (TiO2), can improve the wettability of the heat transfer surfaces, facilitating the formation of a thin, uniform water film during condensation or evaporation processes. This, in turn, enhances the heat transfer coefficient and reduces the formation of water droplets that can impede airflow. Conversely, hydrophobic coatings repel water, preventing the accumulation of moisture and reducing the risk of corrosion and fouling.

Nanostructured and Superhydrophobic Coatings

Building upon the hydrophobic concept, the introduction of nanostructured and superhydrophobic coatings has revolutionized the field of air-cooled heat exchangers. These coatings, inspired by the self-cleaning properties of lotus leaves, can achieve extremely high water contact angles, effectively repelling water and minimizing the adhesion of contaminants. Research has demonstrated that superhydrophobic coatings can improve heat transfer performance by up to 30% and significantly reduce the risk of fouling and corrosion.

Anti-Corrosion and Self-Healing Coatings

Corrosion is a common challenge faced by air-cooled heat exchangers, particularly in harsh environments or marine applications. Innovative anti-corrosion coatings, such as those based on zinc-rich epoxy or specialized ceramic materials, offer enhanced protection against electrochemical and environmental degradation. Furthermore, the development of self-healing coatings, which can autonomously repair minor surface damage, has significantly improved the long-term durability and reliability of heat exchangers.

Thermal Barrier Coatings (TBCs)

In high-temperature applications, such as gas turbines and power generation equipment, thermal barrier coatings (TBCs) have become increasingly important for air-cooled heat exchangers. These multilayered ceramic coatings, typically comprising materials like yttria-stabilized zirconia (YSZ), act as insulation, reducing the heat transfer to the underlying metal substrate and enabling higher operating temperatures without compromising the structural integrity of the heat exchanger.

Surface Modifications for Enhanced Heat Transfer

Beyond protective coatings, various surface modification techniques have been employed to optimize the heat transfer performance of air-cooled heat exchangers. These include techniques like surface roughening, micropatterning, and the application of heat transfer-enhancing nanomaterials. Studies have shown that such surface modifications can increase the heat transfer coefficient by up to 40%, leading to more efficient thermal management and energy savings.

Maintenance and Operational Considerations

Alongside advancements in materials and coatings, the maintenance and operational practices of air-cooled heat exchangers have also evolved to ensure optimal performance and extended service life.

Fouling Mitigation Strategies

Fouling, the accumulation of contaminants on the heat transfer surfaces, is a common challenge in air-cooled heat exchangers. Innovative fouling mitigation strategies, such as the use of automated cleaning systems or the incorporation of self-cleaning coatings, have become increasingly prevalent. These solutions help maintain optimal heat transfer efficiency and reduce the frequency of manual cleaning, leading to reduced downtime and maintenance costs.

Intelligent Monitoring and Predictive Maintenance

The integration of advanced sensors, data analytics, and predictive maintenance algorithms has revolutionized the way air-cooled heat exchangers are monitored and maintained. By continuously tracking parameters like vibration, temperature, and pressure drop, operators can detect early signs of performance degradation, enabling proactive maintenance and minimizing the risk of unexpected failures.

Operational Optimization and Energy Efficiency

Air-cooled heat exchangers are significant contributors to energy consumption in various industrial processes. By optimizing the operational parameters, such as fan speed, airflow, and air distribution, operators can achieve substantial energy savings while maintaining the required heat transfer performance. Additionally, the integration of advanced control systems and machine learning algorithms can further enhance the energy efficiency of air-cooled heat exchangers.

Conclusion

The advancements in materials and coatings for air-cooled heat exchangers have significantly transformed the landscape of thermal management in industrial applications. From innovative composite materials and ceramic-based solutions to cutting-edge coatings and surface modifications, the industry has witnessed a remarkable evolution in heat exchanger design and performance.

By leveraging these technological advancements, air-cooled heat exchanger manufacturers and suppliers can now offer improved heat transfer efficiency, enhanced durability, and reduced maintenance requirements, ultimately contributing to the overall sustainability and competitiveness of industrial processes. As the demand for energy-efficient and environmentally-friendly solutions continues to grow, the continued development and adoption of these innovative materials and coatings will be crucial in shaping the future of air-cooled heat exchanger technology.