Revolutionizing Thermal Management through Additive Manufacturing

In the ever-evolving landscape of aerospace engineering, the demand for high-performance, resilient, and adaptable heat exchangers has never been more pressing. As technological advancements push the boundaries of what’s possible, engineers are turning to the transformative power of additive manufacturing (AM) to overcome the limitations of traditional manufacturing methods and design heat exchangers that excel in both form and function.

Aerospace heat exchangers operate under extreme conditions, subjected to a myriad of challenges, from space constraints and dynamic stress loads to the need for enhanced thermal management and structural integrity. Addressing these diverse requirements has become a pivotal concern for engineers tasked with ensuring the reliable performance and longevity of these critical components.

Additive manufacturing offers a game-changing solution, empowering engineers to design and fabricate heat exchangers with intricate internal flow structures that optimize thermal efficiency and structural resilience. By leveraging the design freedom afforded by AM, engineers can create tailored solutions that push the boundaries of what’s possible, redefining the future of air-cooled heat exchangers.

Unlocking Design Potential with Additive Manufacturing

Conventional manufacturing methods, such as subtractive processes, often struggle to produce the complex geometries and intricate internal features required for optimal heat exchanger performance. Additive manufacturing, on the other hand, enables the fabrication of heat exchangers with unprecedented design flexibility, allowing engineers to explore and realize structures that were once deemed too complex or impractical.

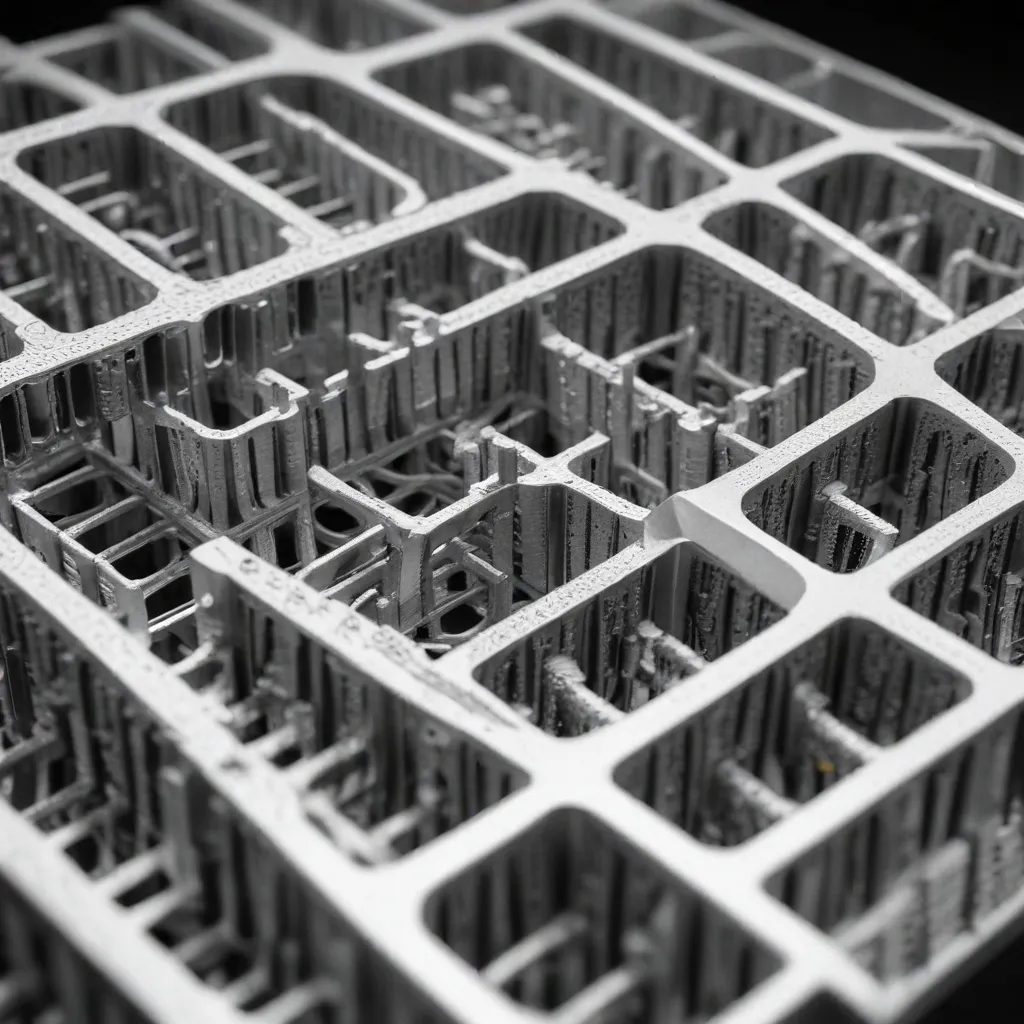

One of the key advantages of AM lies in its ability to create heat exchangers with highly customized internal flow paths. These intricate flow structures, including features like lattices, gyroids, and diamond patterns, can dramatically enhance heat transfer efficiency by increasing the surface area-to-volume ratio and promoting turbulent flow. This, in turn, translates to improved thermal management, a crucial aspect for aerospace applications where heat dissipation is paramount.

Moreover, the design freedom afforded by AM extends beyond just the internal geometry. Engineers can also optimize the external form of the heat exchanger, tailoring the size, shape, and integration with surrounding components to address specific space constraints and system requirements. This level of customization is simply not feasible with traditional manufacturing methods, which are often limited by the inherent constraints of tooling and molds.

Enhancing Structural Integrity and Performance

In the aerospace industry, where safety and reliability are paramount, the structural integrity of heat exchangers is of utmost importance. Additive manufacturing empowers engineers to design heat exchangers with enhanced structural performance, addressing the unique challenges posed by the harsh operating environments encountered in aerospace applications.

One of the key ways AM can improve structural integrity is through the incorporation of advanced internal geometries, such as lattices and honeycomb structures. These engineered patterns not only improve heat transfer but also provide superior strength-to-weight ratios, making the heat exchanger more resistant to deformation, fatigue, and failure under extreme loads.

Furthermore, AM enables the consolidation of multiple components into a single, monolithic structure, reducing the number of potential failure points and streamlining the assembly process. This part consolidation approach not only enhances the overall structural integrity but also simplifies maintenance and reduces the risk of leaks or seal failures, which can be common issues in traditional heat exchanger designs.

By leveraging AM, engineers can also optimize the material selection and distribution within the heat exchanger, ensuring that the components are fabricated from the most suitable materials for the specific application and operating conditions. This allows for the creation of heat exchangers that are both lightweight and resilient, capable of withstanding the demanding stresses and temperature extremes encountered in aerospace environments.

Accelerating the Design-to-Manufacture Process

Traditional manufacturing methods often involve lengthy and iterative design processes, with significant lead times between conceptualization and the production of a physical prototype. Additive manufacturing, however, offers a significant advantage in this regard, enabling a more streamlined and efficient design-to-manufacture workflow.

With AM, engineers can rapidly iterate on their designs, testing and refining the internal flow structures, external geometry, and structural features in a matter of days or even hours. This rapid prototyping capability allows for quick validation of design concepts, enabling engineers to swiftly identify and address performance bottlenecks or potential failure points.

Moreover, the direct digital manufacturing capabilities of AM eliminate the need for costly and time-consuming tooling, molds, or other production-specific equipment. This, in turn, reduces the barriers to entry and enables manufacturers to respond more quickly to evolving market demands or changing customer requirements.

As the aerospace industry continues to push the boundaries of what’s possible, the ability to rapidly develop and implement innovative heat exchanger designs becomes increasingly crucial. Additive manufacturing empowers engineers to stay ahead of the curve, accelerating the design-to-manufacture process and ensuring that the heat exchangers powering the next generation of aerospace technologies are both highly efficient and structurally robust.

Designing for Adaptability and Resilience

In an industry as dynamic as aerospace, where technological advancements and evolving system requirements are the norm, the need for adaptable and resilient heat exchangers has become paramount. Additive manufacturing equips engineers with the tools and flexibility to design heat exchangers that can evolve and adapt to changing demands, ensuring long-term performance and reliability.

One of the key benefits of AM-produced heat exchangers is their ability to accommodate future upgrades or system changes. By leveraging the design freedom afforded by additive manufacturing, engineers can create heat exchanger designs that are modular, allowing for the easy integration of new components or the replacement of outdated parts. This modularity not only simplifies maintenance and upgrades but also enhances the overall longevity of the heat exchanger.

Furthermore, the intricate internal flow structures enabled by AM can be tailored to accommodate a wide range of fluid types, temperatures, and pressures. This adaptability ensures that the heat exchanger can maintain optimal performance even as the system requirements evolve, reducing the need for costly and time-consuming redesigns or replacements.

Additive manufacturing also presents opportunities to enhance the resilience of heat exchangers, enabling the creation of designs that can withstand unexpected operational stresses or environmental conditions. By incorporating features like reinforced structural elements, energy-absorbing lattices, or tailored material distributions, engineers can develop heat exchangers that are better equipped to withstand the harsh realities of the aerospace environment.

Unlocking the Future of Air-Cooled Heat Exchangers

As the aerospace industry continues to push the boundaries of what’s possible, the role of air-cooled heat exchangers has become increasingly critical. Additive manufacturing has emerged as a transformative technology, empowering engineers to design and fabricate heat exchangers that redefine the limits of thermal management and structural performance.

By leveraging the design freedom and rapid prototyping capabilities of AM, engineers can create tailored solutions that address the unique challenges faced by aerospace heat exchangers. From the optimization of internal flow structures to the consolidation of components and the enhancement of structural integrity, additive manufacturing offers a versatile and powerful toolset that is reshaping the future of air-cooled heat exchanger technology.

As the industry continues to evolve, the Air Cooled Heat Exchangers blog will continue to be a valuable resource, providing in-depth insights, practical tips, and expert perspectives on the latest advancements in this critical field. Stay tuned for more cutting-edge content that explores the frontiers of thermal engineering and the transformative impact of additive manufacturing on air-cooled heat exchanger design and performance.