In the ever-evolving world of thermal management, air-cooled heat exchangers have emerged as a versatile and efficient solution, playing a crucial role in a wide range of industrial applications. As technology advances, the demand for customizable and high-performance heat exchangers has grown, leading to the exploration of innovative manufacturing techniques such as additive manufacturing (AM). This article delves into the exciting realm of additive manufacturing of air-cooled heat exchangers, showcasing the advantages of this approach and the potential for creating customized fin structures to optimize thermal performance.

The Rise of Additive Manufacturing in Heat Exchanger Design

Additive manufacturing, also known as 3D printing, has revolutionized the way we approach product design and development across various industries. This technology allows for the fabrication of complex geometries and intricate features that were previously challenging or even impossible to achieve through traditional manufacturing methods. In the realm of air-cooled heat exchangers, additive manufacturing offers a unique opportunity to create highly customized fin structures, tailored to the specific needs of the application.

Customized Fin Geometries

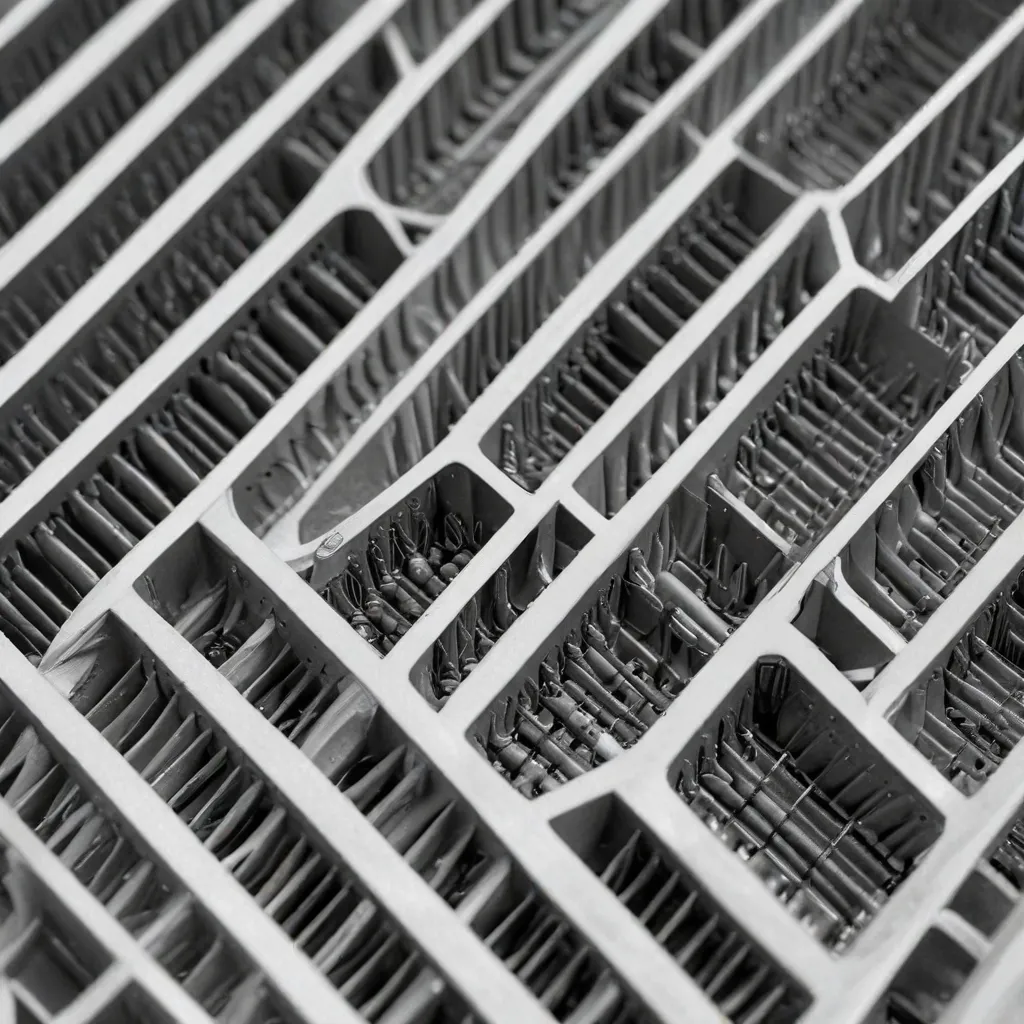

One of the key advantages of additive manufacturing in the context of air-cooled heat exchangers is the ability to design and fabricate intricate fin structures. Conventional manufacturing techniques such as stamping or extrusion often impose limitations on the complexity and versatility of fin geometries. In contrast, additive manufacturing empowers engineers to explore a vast array of fin designs, including:

- Lattice structures: Intricate, interconnected lattice patterns that can enhance surface area and promote turbulent airflow for improved heat transfer.

- Micro-channel fins: Densely packed, microscale channels within the fins that increase heat dissipation efficiency.

- Functionally graded fins: Fins with variable thickness or density, tailored to optimize heat transfer in specific regions of the heat exchanger.

- Bioinspired fin designs: Shapes and patterns inspired by nature, such as fractal-like structures or fin arrangements that mimic the efficient cooling mechanisms found in biological systems.

By leveraging the design freedom offered by additive manufacturing, engineers can create customized fin structures that better match the thermal requirements of the application, leading to enhanced heat transfer performance and improved overall efficiency.

Material Selection and Versatility

Additive manufacturing also provides a diverse range of material options for the fabrication of air-cooled heat exchangers. In addition to traditional materials like aluminum and copper, AM techniques enable the use of advanced materials, such as:

- Ceramics: High-temperature ceramics can be employed in heat exchangers operating in harsh environments or at elevated temperatures.

- Composites: Combining materials like carbon fiber or graphene with metals can result in heat exchangers with improved thermal conductivity, reduced weight, or enhanced corrosion resistance.

- Functionally graded materials: Gradients in material composition can be designed to optimize thermal and structural properties within a single heat exchanger component.

The versatility of additive manufacturing in material selection allows engineers to tailor the heat exchanger’s performance, durability, and even aesthetics to meet the specific requirements of the application.

Optimizing Heat Transfer Performance

The customization capabilities of additive manufacturing extend beyond just the fin structures; they also enable the optimization of overall heat exchanger performance. By leveraging computational fluid dynamics (CFD) simulations and advanced design tools, engineers can virtually prototype and evaluate various heat exchanger designs before physical fabrication.

Airflow Optimization

One of the key factors in air-cooled heat exchanger performance is the efficient management of airflow. Additive manufacturing allows for the creation of intricate flow channels, baffles, and other geometric features that can be used to:

- Enhance air turbulence: Introducing controlled turbulence in the airflow can significantly improve heat transfer rates.

- Reduce pressure drops: Carefully designed air passages can minimize pressure losses, improving the overall system efficiency.

- Optimize airflow distribution: Customized inlet and outlet configurations can ensure uniform air distribution across the heat exchanger surfaces.

By leveraging computational fluid dynamics simulations, engineers can virtually explore and refine these airflow optimization strategies, ensuring the final heat exchanger design delivers maximum thermal performance.

Thermal-Structural Integration

Additive manufacturing also enables the integration of thermal and structural considerations within a single heat exchanger component. This approach can lead to improved overall performance and reliability, as the design can be optimized to withstand the mechanical stresses and thermal loads experienced during operation.

For example, additive manufacturing can facilitate the incorporation of internal features like heat pipes or vapor chambers, which can enhance heat transfer and provide passive cooling mechanisms. Additionally, the ability to create functionally graded materials or complex geometries can help mitigate thermal stresses and ensure the structural integrity of the heat exchanger.

Maintenance and Reliability Considerations

In addition to enhanced thermal performance, the use of additive manufacturing in air-cooled heat exchanger design can also address maintenance and reliability concerns. The customization capabilities of this technology can be leveraged to create heat exchangers that are more resilient to the challenges often faced in industrial environments.

Corrosion and Fouling Resistance

Certain industrial applications, such as the meat processing industry, can expose heat exchangers to harsh environmental conditions, leading to issues like corrosion and fouling. Additive manufacturing allows for the incorporation of specialized surface treatments or geometries that can improve the heat exchanger’s resistance to these challenges.

For instance, the design of the fin structures can be optimized to minimize the accumulation of debris or contaminants, facilitating easier cleaning and maintenance. Furthermore, the integration of corrosion-resistant materials or coatings can enhance the long-term durability of the heat exchanger in demanding environments.

Increased Reliability and Lifespan

The customization capabilities of additive manufacturing can also contribute to improved reliability and extended lifespan of air-cooled heat exchangers. By optimizing the structural integrity and thermal-mechanical integration, the risk of premature failure or degradation can be significantly reduced.

Moreover, the ability to incorporate repair or replacement features directly into the heat exchanger design can simplify maintenance and reduce downtime. For example, additive manufacturing can enable the fabrication of modular components that can be easily swapped out, allowing for efficient servicing and maintenance.

Conclusion

The intersection of additive manufacturing and air-cooled heat exchanger design presents a promising frontier for thermal management solutions. By leveraging the design freedom and customization capabilities of AM, engineers can create innovative fin structures, optimize airflow and heat transfer, and enhance the reliability and durability of these critical components.

As the technology continues to evolve, the Air Cooled Heat Exchangers industry can expect to witness a transformative shift in the way air-cooled heat exchangers are designed, fabricated, and deployed across diverse industrial applications. The future of air-cooled heat exchanger performance and efficiency is undoubtedly shaped by the advancements in additive manufacturing, empowering engineers to push the boundaries of thermal management innovation.