Unlocking the Secrets of Reliable and Efficient Air-Cooled Heat Exchanger Performance

As a seasoned expert in the field of air-cooled heat exchangers, I’ve witnessed firsthand the critical role these systems play in the automotive manufacturing industry. From optimizing production line efficiencies to safeguarding mission-critical equipment, air-cooled heat exchangers are the unsung heroes that enable seamless operations. However, ensuring compliance and safety in their maintenance, inspection, and lifecycle management is paramount.

In this comprehensive article, we’ll dive deep into the practical tips and in-depth insights necessary to maintain air-cooled heat exchanger systems in the automotive sector, addressing key areas such as design, engineering, performance optimization, and regulatory compliance. Whether you’re a plant manager, maintenance technician, or sustainability champion, this guide will equip you with the knowledge to keep your operations running smoothly and safely.

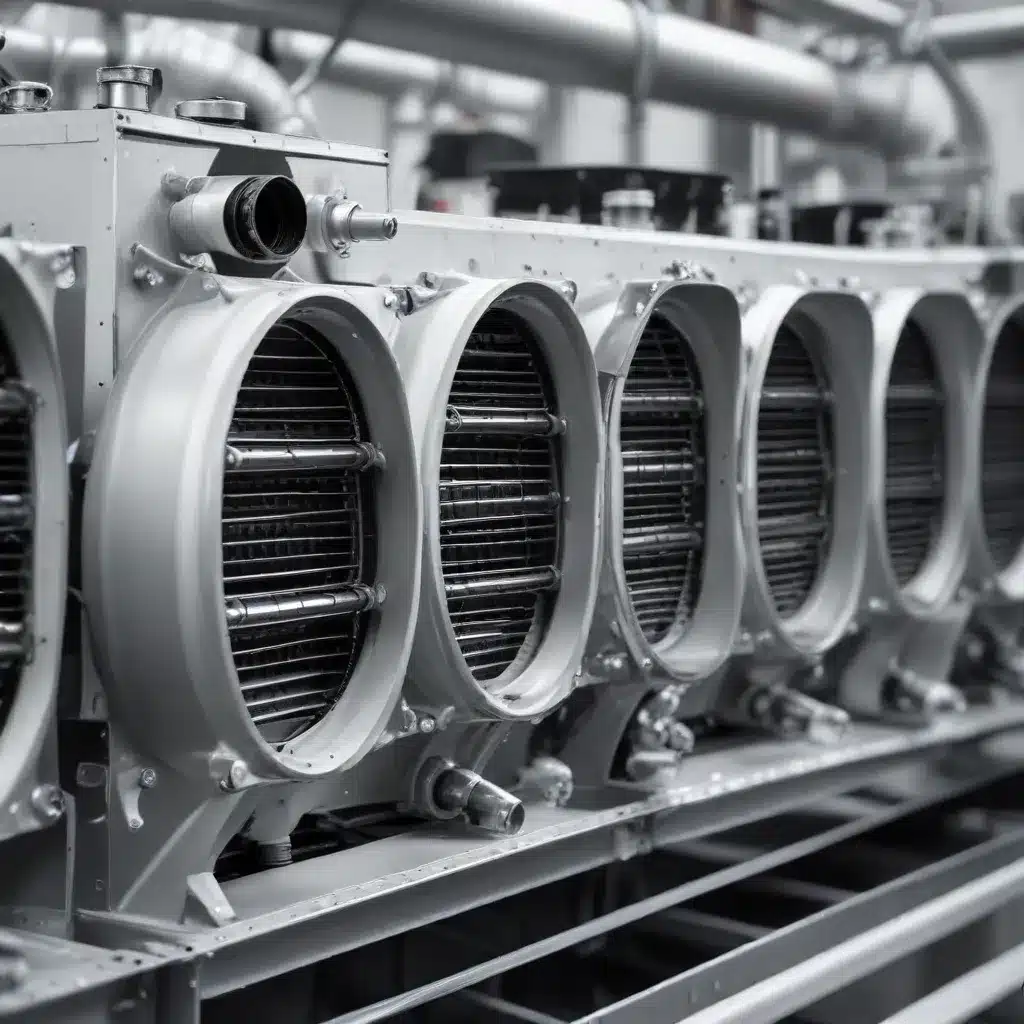

Understanding the Fundamentals of Air-Cooled Heat Exchanger Design and Engineering

At the heart of any effective air-cooled heat exchanger system lies its robust design and engineering. Manufacturers in the automotive industry must carefully consider a multitude of factors, including thermal efficiency, material compatibility, and regulatory compliance, to ensure optimal performance and longevity.

One of the most critical aspects of air-cooled heat exchanger design is the selection of suitable materials. According to the International Finance Corporation’s General EHS Guidelines, materials should be chosen based on their resistance to corrosion, thermal expansion, and mechanical stress, as well as their ability to withstand the operating environment. For instance, aluminum alloys are a popular choice due to their lightweight, high thermal conductivity, and corrosion resistance, making them well-suited for automotive applications.

In addition to material selection, the design of the heat exchanger’s airflow management system is paramount. Effective airflow optimization can significantly improve thermal efficiency and reduce energy consumption. This may involve the use of specialized fans, baffles, or louvers to ensure uniform air distribution across the heat transfer surfaces. Air Force Instruction 24-302 provides detailed guidelines on the proper design and installation of air-cooled heat exchangers to ensure optimal performance and compliance with relevant standards.

Maintenance and Inspection Practices for Ensuring Reliable Air-Cooled Heat Exchanger Operations

Maintaining the integrity and efficiency of air-cooled heat exchanger systems is a critical responsibility for automotive manufacturers. Adhering to a comprehensive maintenance and inspection program is essential to prevent costly downtime, ensure worker safety, and extend the lifespan of these vital components.

One of the primary maintenance tasks for air-cooled heat exchangers is regular cleaning. As dust, debris, and contaminants accumulate on the heat transfer surfaces, they can significantly impair thermal efficiency and lead to premature degradation. Periodic cleaning using compressed air, soft-bristle brushes, or specialized cleaning solutions can help maintain optimal heat transfer rates and extend the exchanger’s operational life.

In addition to cleaning, routine inspections are crucial to identifying and addressing potential issues before they escalate. This may include visual assessments for signs of corrosion, damage, or fouling, as well as performance testing to verify proper airflow, pressure drop, and heat transfer characteristics. AFI 24-302 outlines comprehensive guidelines for conducting these inspections and maintaining detailed records to ensure compliance and safety.

Optimizing Air-Cooled Heat Exchanger Performance and Extending Lifecycle

Beyond the fundamental maintenance and inspection practices, automotive manufacturers can further enhance the performance and lifespan of their air-cooled heat exchanger systems through a variety of optimization strategies and lifecycle management techniques.

One effective approach is to implement a proactive maintenance program that incorporates predictive analytics and condition-based monitoring. By continuously monitoring key performance indicators, such as vibration, temperature, and pressure, maintenance teams can identify potential issues before they escalate, allowing for targeted interventions and minimizing unplanned downtime.

Another crucial aspect of lifecycle management is the proper selection and replacement of critical components. As air-cooled heat exchangers age, certain parts may become worn or inefficient, necessitating timely upgrades or replacements. By closely tracking the performance and condition of individual components, manufacturers can optimize their replacement schedules and ensure the long-term reliability of their systems.

Ensuring Regulatory Compliance and Safety in Air-Cooled Heat Exchanger Operations

Maintaining compliance with relevant safety standards and regulations is a top priority for automotive manufacturers when it comes to air-cooled heat exchanger systems. Failure to adhere to these guidelines can not only result in costly fines and legal liabilities but also jeopardize the safety of workers and the broader production environment.

The International Finance Corporation’s General EHS Guidelines provide a comprehensive framework for managing environmental, health, and safety (EHS) risks associated with industrial operations, including the proper handling and maintenance of air-cooled heat exchangers. These guidelines outline best practices for hazard identification, risk assessment, and the implementation of effective control measures to protect workers and the surrounding community.

Additionally, AFI 24-302 outlines specific requirements for the inspection, maintenance, and documentation of air-cooled heat exchanger systems, ensuring compliance with relevant safety and environmental regulations. By adhering to these guidelines, automotive manufacturers can demonstrate their commitment to safety and sustainability, bolstering their reputation and mitigating potential legal and financial risks.

Integrating Air-Cooled Heat Exchanger Systems into Broader Sustainability Initiatives

As the automotive industry continues to evolve towards more environmentally conscious practices, the role of air-cooled heat exchanger systems in supporting broader sustainability initiatives cannot be overstated. By optimizing the performance and efficiency of these critical components, manufacturers can contribute to reduced energy consumption, lower greenhouse gas emissions, and enhanced resource conservation.

One example of this integration can be seen in the Textron Specialized Vehicles facility in Cartersville, Georgia, where air-cooled heat exchangers play a crucial role in the production of their specialized vehicles. By implementing robust maintenance and inspection protocols, the company has been able to maximize the efficiency of its air-cooled heat exchangers, reducing energy demands and contributing to its overall sustainability initiatives.

Moreover, the data collected through advanced monitoring and predictive analytics can provide valuable insights into the long-term performance and environmental impact of air-cooled heat exchanger systems. This information can then be leveraged to make informed decisions about equipment upgrades, process improvements, and the integration of emerging technologies, such as renewable energy sources or waste heat recovery systems.

Conclusion: Elevating Air-Cooled Heat Exchanger Management for Sustained Automotive Excellence

In the dynamic and ever-evolving automotive manufacturing sector, the effective management of air-cooled heat exchanger systems is a critical component of operational excellence, safety, and sustainability. By embracing a comprehensive approach to design, engineering, maintenance, and lifecycle optimization, automotive manufacturers can unlock the full potential of these vital systems, ensuring compliance, enhancing productivity, and contributing to a more sustainable future.

As you embark on your journey to optimize your air-cooled heat exchanger systems, remember to stay vigilant, embrace innovation, and prioritize the safety and well-being of your workforce. By following the guidance and best practices outlined in this article, you can position your automotive manufacturing operations for long-term success, resilience, and environmental responsibility.

For more information and resources on air-cooled heat exchanger management, be sure to visit the Air Cooled Heat Exchangers website, where you’ll find a wealth of industry-leading insights and practical solutions to help you navigate the complexities of this vital field.