The Role of Advanced Materials in Pushing the Boundaries of Air-Cooled Heat Exchangers

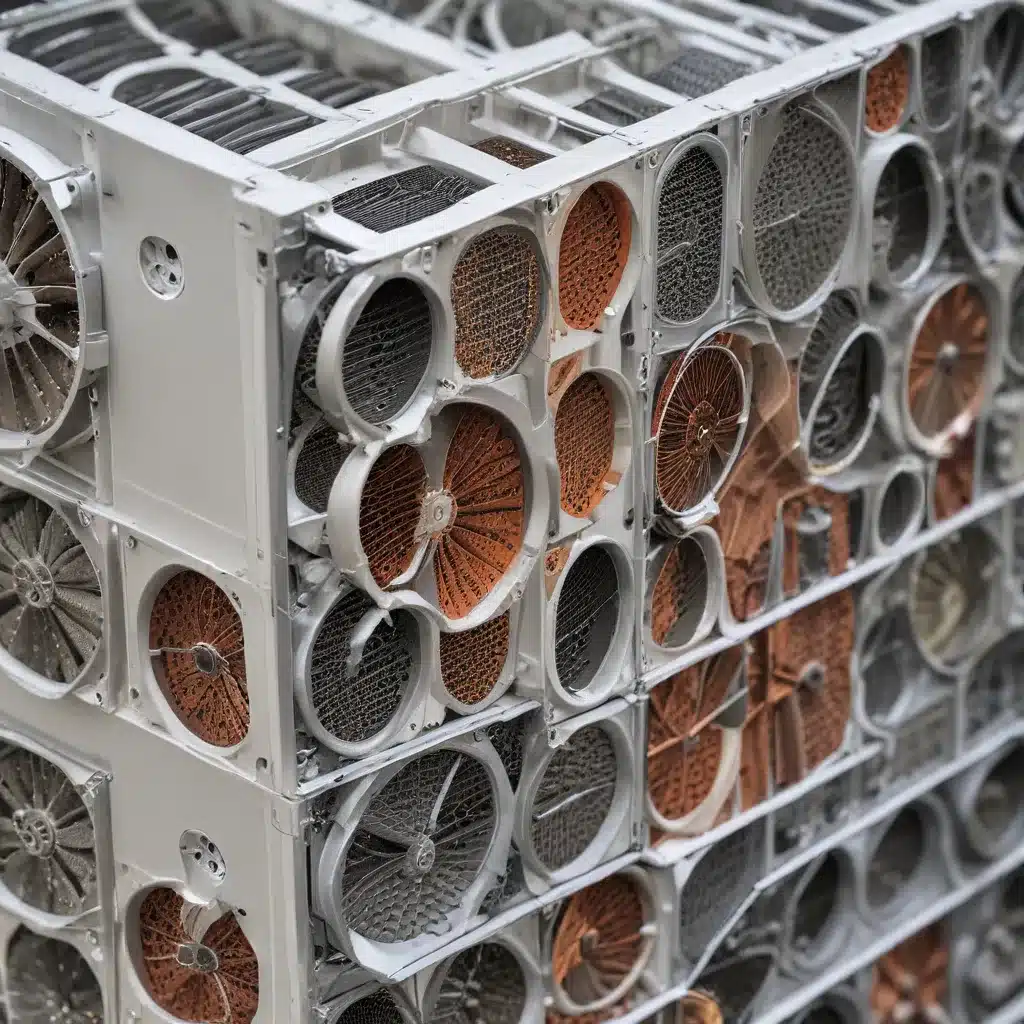

As the global demand for energy efficiency and environmentally sustainable solutions continues to rise, the importance of air-cooled heat exchangers has never been more paramount. These critical components play a vital role in a wide range of industries, from power generation and manufacturing to HVAC and transportation. However, as technology continues to evolve, the operational requirements for air-cooled heat exchangers have become increasingly demanding, pushing the limits of traditional materials and design.

Enter the realm of advanced materials – a diverse and rapidly evolving field that is transforming the landscape of air-cooled heat exchanger technology. From high-purity graphite and silicon carbide coatings to cutting-edge ceramic composites, these innovative materials are revolutionizing the way we approach thermal management, delivering enhanced thermal stability, durability, and efficiency in even the most extreme operating conditions.

Graphite: The Workhorse of Air-Cooled Heat Exchanger Components

At the heart of many air-cooled heat exchanger systems lies the humble, yet indispensable, material known as graphite. As a key player in the semiconductor industry, Mersen has long recognized the pivotal role of graphite in air-cooled heat exchanger design and engineering. Mersen’s advanced graphite solutions offer exceptional thermal stability, making them essential for maintaining precise temperature control within critical components like epitaxy reactors and silicon crystal growth furnaces.

The exceptional thermal properties of graphite, combined with its resistance to oxidation and corrosion, make it an ideal choice for a wide range of air-cooled heat exchanger applications. From the high-purity graphite electrodes used in the Siemens process for polysilicon manufacturing to the isostatic graphite crucibles employed in silicon crystal growth, Mersen’s graphite-based solutions are at the forefront of ensuring the efficiency and reliability of these critical industrial processes.

Enhancing Graphite Performance with Advanced Coatings

While graphite’s inherent properties make it a valuable material in air-cooled heat exchanger design, it is not without its limitations. Graphite’s susceptibility to oxidation at high temperatures can pose a challenge in applications where it is exposed to harsh environments or extreme thermal conditions. This is where advanced coatings come into play.

Mersen’s expertise in materials science has led to the development of innovative coating solutions that enhance the durability and longevity of graphite components. Silicon Carbide (SiC) and Tantalum Carbide (TaC) coatings are applied to graphite parts to create a protective barrier against erosion, oxidation, and contamination. These coatings not only extend the lifespan of the graphite components but also help maintain the purity and integrity of the materials used in critical semiconductor manufacturing processes.

Harnessing the Power of Silicon Carbide for High-Performance Semiconductors

As the semiconductor industry continues to push the boundaries of technology, the demand for materials with superior electrical and thermal properties has become increasingly evident. Silicon carbide (SiC) has emerged as a game-changer in this domain, offering a host of advantages over traditional silicon-based semiconductors.

Mersen’s involvement in the development of SmartSiC™ technology – a groundbreaking approach to creating composite SiC substrates – highlights the company’s commitment to advancing semiconductor manufacturing. The unique properties of the SmartSiC™ substrate, including its enhanced thermal conductivity and mechanical strength, have the potential to revolutionize the production of high-efficiency, durable power electronics components, particularly for the electric vehicle industry.

Precision Epitaxy: The Cornerstone of Semiconductor Fabrication

At the heart of semiconductor manufacturing lies the critical process of epitaxy, where precisely controlled layers of materials are deposited onto a substrate to create the intricate structures that power our digital world. Maintaining precise control over the temperature, material composition, and deposition parameters during epitaxy is essential for ensuring the quality and performance of the final semiconductor devices.

Mersen’s advanced materials, including high-purity graphite, SiC-coated components, and tailored wafer carriers, play a pivotal role in supporting the evolving demands of epitaxial processes. These materials provide the necessary thermal stability, corrosion resistance, and dimensional precision to enable the fabrication of semiconductor devices with ever-increasing complexity and efficiency.

Addressing Thermal Management Challenges in Air-Cooled Heat Exchanger Design

As air-cooled heat exchanger systems continue to operate in more demanding environments, the challenges of thermal management become increasingly critical. Maintaining precise temperature control and ensuring consistent heat distribution are paramount for optimizing the performance and efficiency of these critical components.

Mersen’s expertise in advanced materials, such as porous graphite, rigid carbon insulation, and soft felt carbon insulation, is instrumental in addressing these thermal management challenges. These materials excel in providing superior thermal insulation and maintaining the necessary temperature uniformity within air-cooled heat exchanger systems, enabling them to operate at peak efficiency and reliability, even in the most extreme conditions.

Conclusion: Shaping the Future of Air-Cooled Heat Exchanger Technology

The advancements in air-cooled heat exchanger materials are not merely incremental improvements; they represent a transformative shift in the way we approach thermal management and energy efficiency across a wide range of industries. By harnessing the power of innovative materials like high-purity graphite, silicon carbide, and advanced ceramic composites, Mersen is at the forefront of driving the next generation of air-cooled heat exchanger technology.

As the global demand for sustainable, high-performance, and reliable thermal management solutions continues to grow, the critical role of advanced materials in air-cooled heat exchanger design will only become more pivotal. By leveraging its expertise in materials science and semiconductor manufacturing, Mersen is poised to lead the charge in unlocking the full potential of air-cooled heat exchangers, empowering industries to meet the evolving challenges of the future.