As the automotive and transportation industries continue to evolve, the demand for efficient and reliable thermal management systems has become increasingly critical. Air-cooled heat exchangers have emerged as a versatile and cost-effective solution, offering a wide range of applications across various vehicle types, from traditional internal combustion engines to the rapidly growing electric vehicle (EV) market.

Optimizing Thermal Management in Electric Vehicles

The burgeoning EV industry has become a crucial player in tackling environmental pollution and addressing the global demand for sustainable transportation. However, as these vehicles continue to advance, effective thermal management systems are essential to ensure battery safety, optimize energy utilization, and prolong vehicle lifespan.

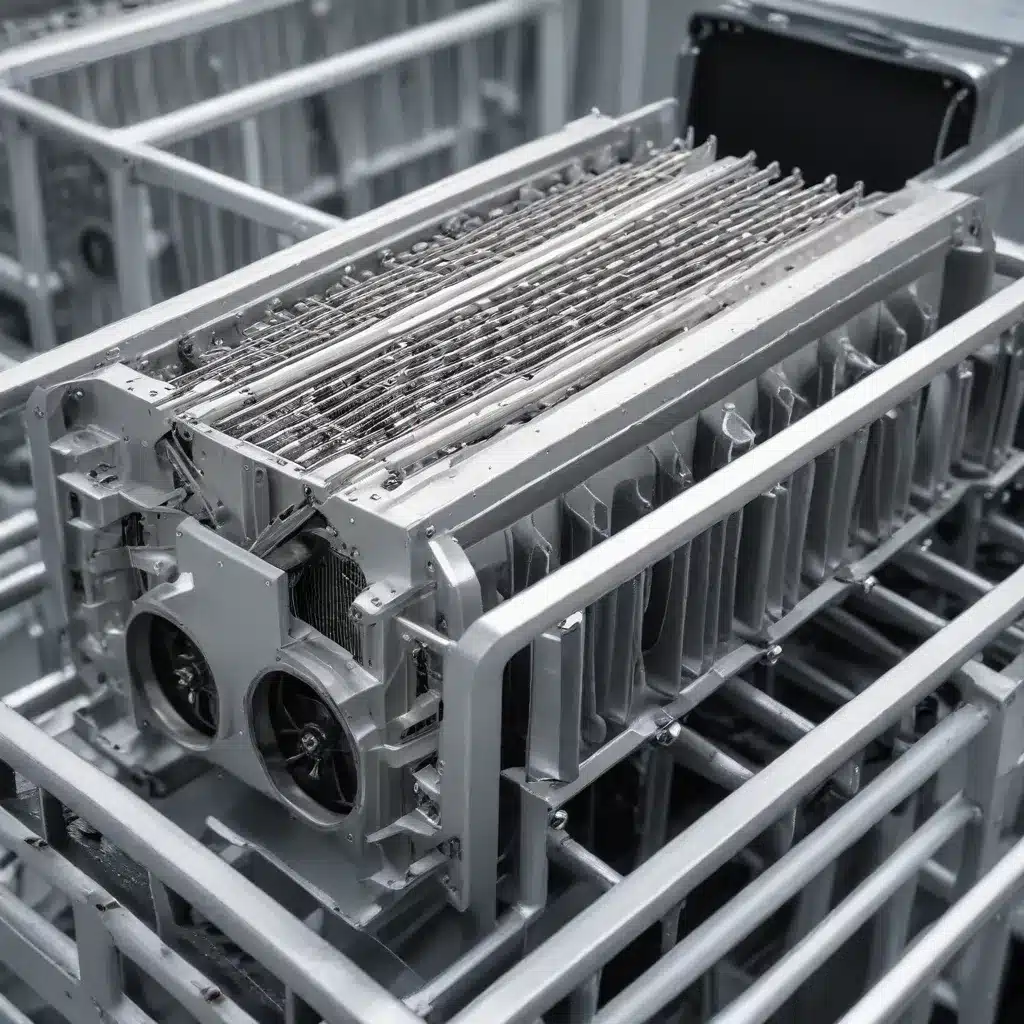

One of the primary challenges faced by EV manufacturers is the efficient cooling of the vehicle’s power battery pack. Overheating can lead to reduced battery performance, shortened lifespan, and, in extreme cases, even safety hazards. Air-cooled heat exchangers have emerged as a viable solution, offering a compact and lightweight design that can be seamlessly integrated into the vehicle’s architecture.

By leveraging the inherent advantages of air-cooled technology, such as simplicity, low maintenance, and scalability, manufacturers can develop robust battery thermal management systems (BTMS) that effectively dissipate the heat generated during charging and discharging cycles. This not only enhances battery performance and longevity but also improves the overall energy efficiency of the EV, leading to increased driving range and reduced operating costs.

Enhancing Thermal Management in Electric Motors

In addition to battery cooling, the thermal management of electric motors is another critical aspect in the EV industry. Electric motors generate significant heat during operation, and effective cooling is necessary to maintain optimal performance, prevent premature wear, and ensure the overall reliability of the drivetrain.

Air-cooled heat exchangers can be strategically integrated into the motor’s cooling system, leveraging the vehicle’s airflow to efficiently remove the excess heat. This approach not only enhances the motor’s efficiency but also contributes to the overall thermal management of the EV, as the heat dissipated from the motor can be utilized to support other subsystems, such as cabin heating or battery temperature regulation.

By optimizing the design and placement of air-cooled heat exchangers within the motor’s cooling system, engineers can achieve a delicate balance between performance, reliability, and energy efficiency, ultimately enhancing the overall driving experience and the vehicle’s environmental impact.

Integrating Air-Cooled Heat Exchangers into HVAC Systems

Beyond the thermal management of batteries and electric motors, air-cooled heat exchangers play a crucial role in the design and optimization of the vehicle’s HVAC (Heating, Ventilation, and Air Conditioning) system. As the demand for comfortable and energy-efficient cabin climate control continues to grow, the integration of air-cooled heat exchangers into the HVAC system has become a crucial consideration.

By leveraging the inherent efficiency and simplicity of air-cooled technology, manufacturers can develop HVAC systems that seamlessly regulate the cabin temperature, humidity, and air quality, while minimizing the energy consumption and overall impact on the vehicle’s powertrain.

The strategic placement of air-cooled heat exchangers within the HVAC system can also enable the recovery and redistribution of waste heat, further improving the overall energy utilization and contributing to the vehicle’s overall thermal management strategy.

Advancing Air-Cooled Heat Exchanger Design and Materials

As the automotive and transportation industries continue to evolve, the design and materials of air-cooled heat exchangers are also undergoing significant advancements. Researchers and engineers are exploring innovative approaches to improve the heat transfer performance, reduce weight, and enhance the reliability of these critical components.

One such area of focus is the development of advanced heat transfer surfaces, such as finned or micro-channel designs, which can significantly increase the surface area and overall heat dissipation capabilities of the heat exchanger. Additionally, the use of lightweight and corrosion-resistant materials, such as aluminum alloys or advanced composites, can contribute to the overall weight reduction and durability of the system.

Furthermore, the integration of advanced manufacturing techniques, such as additive manufacturing or selective laser melting, can enable the creation of complex and customized heat exchanger geometries, tailored to the specific thermal management requirements of individual vehicle models or applications.

Maintenance and Optimization Strategies for Air-Cooled Heat Exchangers

Ensuring the long-term performance and reliability of air-cooled heat exchangers is crucial for maintaining the overall efficiency and lifespan of automotive and transportation systems. Proactive maintenance and optimization strategies can help maximize the potential of these critical components.

Regular inspection and cleaning of the heat exchanger’s finned surfaces, to remove any accumulated debris or contaminants, can significantly improve the heat transfer efficiency and prevent potential failures. Additionally, the implementation of advanced monitoring and control systems can enable real-time optimization of the heat exchanger’s performance, adjusting the airflow and operating parameters based on the specific thermal demands of the vehicle.

By adopting a comprehensive approach to the maintenance and optimization of air-cooled heat exchangers, vehicle owners and fleet operators can not only extend the lifespan of these components but also enhance the overall energy efficiency and environmental impact of their transportation solutions.

Embracing the Future of Thermal Management in Automotive and Transportation

As the automotive and transportation sectors continue to evolve, the role of air-cooled heat exchangers in improving thermal management and energy efficiency will become increasingly critical. By leveraging the inherent advantages of this technology, manufacturers and industry professionals can develop innovative solutions that address the growing demands for sustainable, reliable, and cost-effective transportation.

From the efficient cooling of electric vehicle batteries and motors to the optimization of HVAC systems, air-cooled heat exchangers offer a versatile and adaptable approach to thermal management that can be tailored to the unique requirements of each application. As research and development continue to push the boundaries of heat exchanger design and materials, the potential for air-cooled technology to shape the future of the automotive and transportation sectors is undeniable.

By embracing the power of air-cooled heat exchangers, the industry can unlock new levels of performance, efficiency, and environmental responsibility, positioning itself at the forefront of the global transition towards a more sustainable and technologically advanced transportation landscape.

To learn more about the latest advancements in air-cooled heat exchanger technology and how it can benefit your automotive or transportation applications, visit https://www.aircooledheatexchangers.net/. Our team of experts is dedicated to providing the insights, resources, and support you need to optimize your thermal management systems and drive the future of sustainable mobility.