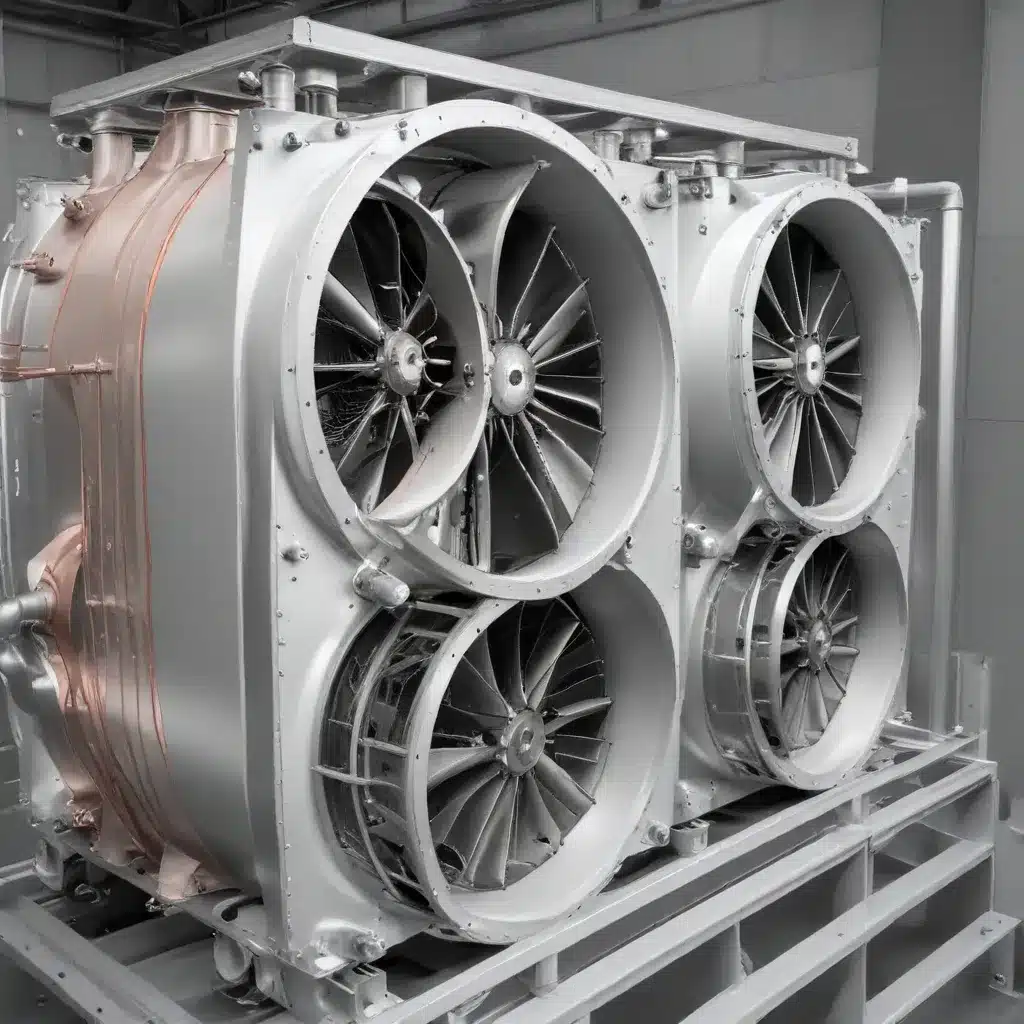

Unlocking the Full Potential of Air-Cooled Heat Exchangers

As a seasoned expert in the field of air-cooled heat exchangers, I’m thrilled to share practical tips and in-depth insights to help you optimize the design, engineering, and performance of these critical components. Whether you’re working in the industrial, power generation, or HVAC sectors, understanding how to enhance heat transfer, minimize noise and vibration, and ensure reliable operation is essential for driving efficiency, sustainability, and cost-effectiveness.

Identifying and Addressing Root Causes of Performance Issues

When it comes to air-cooled heat exchangers, simply replacing a malfunctioning unit is often a short-term solution that fails to address the underlying problems. Instead, we must take a comprehensive, root-cause analysis approach to truly optimize the system and prepare it for the future.

“Our primary goal is to ensure that your processes run reliably and perform optimally. We do not patch up any components; we make new designs and perform thermal calculations. We look at the entire system: we do not treat the symptoms, we look for the cause.”

By delving deep into the thermal calculations, fluid dynamics, and overall system interactions, we can identify the root causes of issues such as poor heat transfer, excessive noise, or elevated vibration levels. This allows us to implement innovative solutions that not only address the immediate problems but also future-proof the system for long-term success.

Optimizing Heat Transfer Performance

One of the key areas of focus in air-cooled heat exchanger design is enhancing heat transfer performance. This can be achieved through a combination of strategic design modifications and the incorporation of advanced technologies.

Fin Design Optimization:

The design of the heat exchanger fins plays a crucial role in its thermal efficiency. By carefully analyzing the fin geometry, material, and arrangement, we can optimize airflow patterns and heat transfer coefficients. This may involve exploring innovative fin designs, such as louvered, wavy, or serrated fins, to disrupt the boundary layer and promote turbulent flow, ultimately boosting heat transfer rates.

Tube Configuration and Arrangement:

The configuration and arrangement of the heat exchanger tubes can also have a significant impact on performance. Experimenting with staggered or in-line tube layouts, as well as adjusting the tube pitch and diameter, can help enhance the heat transfer process and minimize pressure drop, leading to improved overall efficiency.

Advanced Heat Transfer Enhancements:

Beyond traditional design optimizations, the incorporation of cutting-edge heat transfer enhancement techniques can take air-cooled heat exchanger performance to new heights. This may include the use of:

– Nanofluids or microchannel technologies to increase the effective surface area and heat transfer coefficients

– Vortex generators or flow disruptors to induce turbulence and promote better mixing

– Phase-change materials or heat pipes to harness the latent heat of vaporization and condensation

By leveraging these advanced strategies, we can unlock the full potential of air-cooled heat exchangers, ensuring they operate at peak efficiency and meet the ever-evolving demands of modern industrial and commercial applications.

Mitigating Noise and Vibration Concerns

Excessive noise and vibration can be a significant challenge with air-cooled heat exchangers, often leading to premature component failure, reduced system reliability, and compliance issues. To address these concerns, we must take a holistic approach that encompasses both design optimization and maintenance best practices.

Design Strategies for Noise and Vibration Reduction:

– Improving fan and motor selection to minimize speed and imbalance

– Optimizing airflow path and duct design to reduce turbulence and pressure drops

– Implementing vibration-dampening mechanisms, such as flexible connections and isolators

– Selecting materials and construction methods that minimize structural resonance

Proactive Maintenance and Monitoring:

Regular inspections, preventive maintenance, and vibration monitoring are crucial for maintaining the long-term performance and reliability of air-cooled heat exchangers. By closely tracking key parameters, such as fan balance, bearing condition, and structural integrity, we can identify and address potential issues before they escalate into significant problems.

“Suppose a site was built 30 years ago, and the heat exchanger is no longer working properly. A simple replacement could be an option or we could focus on increasing the performance of your equipment within the same plot space.”

By integrating these design and maintenance strategies, we can significantly reduce noise and vibration levels, ensuring a more comfortable and productive work environment while also extending the service life of the air-cooled heat exchanger.

Optimizing for Sustainability and Cost-Effectiveness

In today’s business landscape, where environmental sustainability and operational efficiency are paramount, the optimization of air-cooled heat exchangers must also consider these crucial factors.

Energy Efficiency and Emissions Reduction:

By enhancing heat transfer performance and minimizing pressure drops, we can reduce the energy consumption and associated carbon footprint of air-cooled heat exchangers. This not only contributes to environmental stewardship but also translates to significant cost savings for our clients.

Reduced Maintenance and Downtime:

Optimizing the design and implementing proactive maintenance strategies can lead to extended service life, reduced downtime, and lower maintenance costs for air-cooled heat exchangers. This helps our clients maintain a reliable and efficient system while minimizing the financial burden of frequent repairs or replacements.

“Our performance and reliability improvement is based on: Do you want to know how we can improve the performance of your heat transfer solution? Our specialist will soon get in touch.”

At Air Cooled Heat Exchangers, we are committed to providing our clients with comprehensive solutions that not only address their immediate needs but also prepare them for the future. By leveraging our expertise in thermal engineering, fluid dynamics, and vibration analysis, we can help you unlock the full potential of your air-cooled heat exchangers, driving efficiency, sustainability, and long-term success.