The Evolving Landscape of Thermal Management in Electric Vehicles

The rapid growth of the electric vehicle (EV) industry has presented new challenges and opportunities in thermal management. As these eco-friendly vehicles continue to advance, effective thermal control systems are crucial to ensure battery safety, optimize energy utilization, and prolong the lifespan of critical components. Air-cooled heat exchangers have emerged as a promising solution to address these thermal management needs in the transportation and automotive sectors.

Addressing Thermal Challenges in EV Subsystems

Within an electric vehicle, there are several interconnected subsystems that require robust thermal management strategies. These include:

-

Air Conditioning (AC) Systems: Maintaining a comfortable cabin temperature is essential for occupant satisfaction and energy efficiency. Advanced air-cooled heat exchangers can play a pivotal role in enhancing the performance and efficiency of EV air conditioning systems.

-

Battery Thermal Management Systems: Lithium-ion batteries, the backbone of modern EVs, are highly sensitive to temperature fluctuations. Effective cooling solutions, leveraging air-cooled heat exchangers, are necessary to protect the batteries from overheating and maintain optimal performance.

-

Motor Thermal Management Systems: Electric motors generate significant heat during operation, which must be effectively dissipated to prevent performance degradation and premature failure. Air-cooled heat exchangers can provide an efficient means of cooling these critical drivetrain components.

By addressing the thermal management requirements of these key subsystems, air-cooled heat exchangers can contribute to improved overall energy utilization, extended component lifespan, and enhanced driving experience in electric vehicles.

Advancements in Air-Cooled Heat Exchanger Technology

Air-cooled heat exchangers have undergone significant advancements in design, materials, and manufacturing techniques, making them increasingly suitable for transportation and automotive applications.

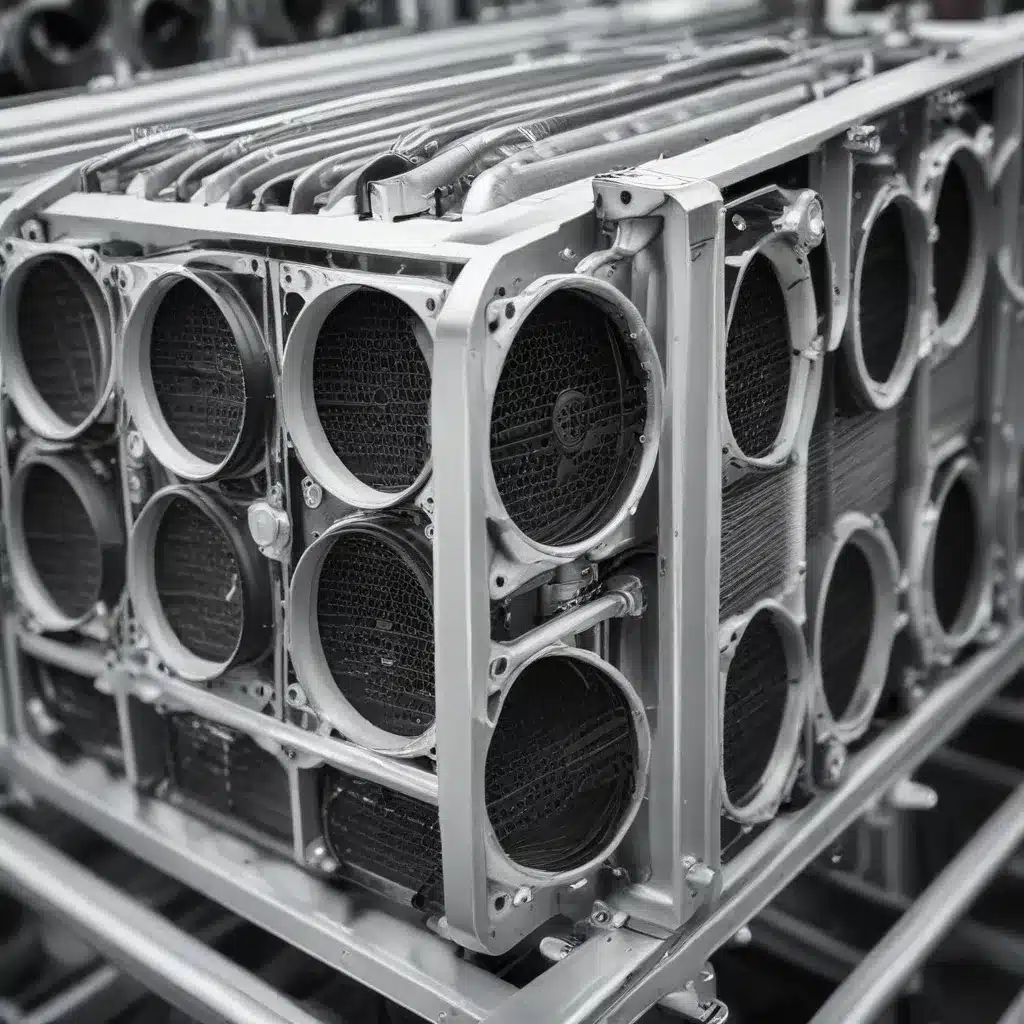

Innovative Heat Exchanger Designs

Researchers and engineers have explored various air-cooled heat exchanger designs to optimize thermal performance, reduce size and weight, and improve integration into vehicle architectures. Some notable innovations include:

- Microchannel Heat Exchangers: These compact, high-efficiency designs leverage micro-scale fluid channels to maximize heat transfer surface area while minimizing overall size and weight.

- Finned Tube Heat Exchangers: Advancements in fin geometries, materials, and manufacturing processes have led to enhanced air-side heat transfer and improved thermal-hydraulic performance.

- Plate-Fin Heat Exchangers: Innovative plate-fin configurations and the use of advanced materials, such as aluminum alloys, have enabled the development of highly compact and efficient air-cooled heat exchangers.

Leveraging Advanced Materials

The selection of materials for air-cooled heat exchangers plays a crucial role in their thermal performance, durability, and cost-effectiveness. Emerging materials, such as advanced aluminum alloys, copper-based alloys, and even lightweight composites, are being explored to enhance the heat transfer capabilities, corrosion resistance, and overall reliability of these heat exchangers.

Optimizing Manufacturing Processes

Advancements in manufacturing techniques, including additive manufacturing, laser welding, and precision machining, have enabled the production of air-cooled heat exchangers with intricate geometries, tighter tolerances, and improved thermal-hydraulic efficiency. These manufacturing innovations can contribute to enhanced reliability, customization, and cost-effectiveness of air-cooled heat exchangers for transportation and automotive applications.

Integrating Air-Cooled Heat Exchangers into Vehicle Thermal Management Systems

The integration of air-cooled heat exchangers into the thermal management systems of electric vehicles requires a comprehensive approach, considering both the component-level and system-level aspects.

Component-Level Integration

At the component level, air-cooled heat exchangers can be designed to seamlessly integrate with various subsystems, such as:

- Air Conditioning (AC) Systems: Air-cooled heat exchangers can serve as the condenser in the AC system, efficiently dissipating the heat generated by the refrigerant compression process.

- Battery Thermal Management Systems: Air-cooled heat exchangers can be utilized to directly cool the battery pack or to cool the intermediate cooling fluid, maintaining the batteries within their optimal temperature range.

- Motor Thermal Management Systems: Air-cooled heat exchangers can be strategically placed to dissipate the heat generated by the electric motor, ensuring consistent performance and reliability.

System-Level Integration

Beyond individual subsystems, the holistic integration of air-cooled heat exchangers into the overall vehicle thermal management system is crucial. This includes:

- Thermal System Architecture: Designing an efficient and comprehensive thermal management system that leverages air-cooled heat exchangers to address the thermal demands of multiple components, while considering factors like packaging, weight, and airflow optimization.

- Control Algorithms: Developing advanced control algorithms that can optimize the operation of air-cooled heat exchangers, balancing the thermal needs of different subsystems and ensuring efficient energy utilization.

- Performance Optimization: Integrating air-cooled heat exchangers into the overall vehicle design to maximize thermal management efficiency, minimize energy consumption, and enhance the overall driving experience.

By adopting a systems-level approach to the integration of air-cooled heat exchangers, vehicle manufacturers can unlock the full potential of these innovative thermal management solutions, leading to improved performance, energy efficiency, and reliability in electric vehicles.

Maintenance and Optimization of Air-Cooled Heat Exchangers in Transportation Applications

Ensuring the long-term reliable operation of air-cooled heat exchangers is crucial for the efficient and consistent thermal management of electric vehicles. Maintenance and optimization strategies play a vital role in maximizing the performance and lifespan of these critical components.

Maintenance Strategies

Effective maintenance practices for air-cooled heat exchangers in transportation applications include:

- Regular Cleaning: Periodically cleaning the heat exchanger surfaces to remove accumulated dirt, debris, and contaminants that can impede airflow and reduce heat transfer efficiency.

- Inspection and Troubleshooting: Regularly inspecting the heat exchanger for any signs of damage, corrosion, or potential performance issues, and promptly addressing any identified problems.

- Preventive Maintenance: Implementing a proactive maintenance schedule, including the replacement of critical components like fans, motors, and seals, to ensure optimal performance and prevent unexpected failures.

Performance Optimization

Continuous optimization of air-cooled heat exchanger performance is essential to maintain the thermal management system’s efficiency and adaptability to changing conditions. Strategies for performance optimization include:

- Airflow Optimization: Evaluating and adjusting the airflow patterns, fan speeds, and duct designs to ensure efficient heat dissipation and minimize pressure drops.

- Thermal Load Balancing: Developing control algorithms that can dynamically adjust the operation of air-cooled heat exchangers to match the varying thermal demands of different vehicle subsystems, optimizing energy usage.

- Condition-Based Monitoring: Implementing real-time monitoring and diagnostic systems to detect any performance degradation or impending failures, enabling proactive maintenance and optimization.

By adopting comprehensive maintenance practices and optimization strategies, vehicle manufacturers can ensure the reliable and efficient operation of air-cooled heat exchangers, contributing to the overall thermal management system’s longevity and performance in electric vehicles.

Exploring the Versatility of Air-Cooled Heat Exchangers in Transportation and Automotive Applications

Beyond the specific challenges faced in electric vehicles, air-cooled heat exchangers have a wide range of applications across the transportation and automotive industries. These versatile thermal management solutions can be leveraged in various contexts, including:

-

Hybrid and Fuel-Efficient Vehicles: Air-cooled heat exchangers can play a crucial role in the thermal management of hybrid vehicles, which require efficient cooling for both the internal combustion engine and the electric drivetrain components.

-

Commercial Trucks and Buses: Heavy-duty vehicles, such as commercial trucks and buses, often have significant thermal management demands due to their powerful engines and the need to maintain comfortable cabin temperatures. Air-cooled heat exchangers can be tailored to meet these specialized requirements.

-

Off-Highway Equipment: Construction, agricultural, and mining equipment often operate in harsh environments, where air-cooled heat exchangers can provide reliable and efficient thermal management solutions to protect critical components.

-

Aerospace and Aviation: The aerospace and aviation industries have long recognized the benefits of air-cooled heat exchangers, using them to manage the thermal loads of aircraft avionics, environmental control systems, and ground support equipment.

By exploring the versatility of air-cooled heat exchangers across these diverse transportation and automotive applications, the Air Cooled Heat Exchangers team can provide valuable insights and tailored solutions to meet the evolving needs of the industry.

Conclusion: Embracing the Future of Thermal Management with Air-Cooled Heat Exchangers

As the transportation and automotive industries continue to evolve, the role of air-cooled heat exchangers in thermal management has become increasingly crucial. These innovative heat transfer solutions offer a range of benefits, including improved energy efficiency, enhanced component reliability, and reduced environmental impact.

By leveraging the advancements in air-cooled heat exchanger design, materials, and manufacturing, vehicle manufacturers can unlock new possibilities in thermal management, addressing the growing thermal challenges posed by electric, hybrid, and advanced propulsion systems. Through a comprehensive, systems-level approach to integration and optimization, air-cooled heat exchangers can play a pivotal role in shaping the future of sustainable and high-performance transportation.

The Air Cooled Heat Exchangers team is committed to staying at the forefront of these advancements, providing industry-leading expertise, practical solutions, and thought-provoking insights to help transportation and automotive companies navigate the evolving landscape of thermal management. By embracing the potential of air-cooled heat exchangers, we can collectively drive towards a more efficient, reliable, and eco-friendly future in the transportation sector.