The Evolving Role of Air-Cooled Heat Exchangers in Thermal Management

As technological advancements continue to drive innovation across industries, the demand for efficient and reliable thermal management solutions has never been more critical. Air-cooled heat exchangers (HEXs) have emerged as a versatile and essential component in this pursuit, playing a pivotal role in maintaining the operational integrity of a wide range of systems and applications.

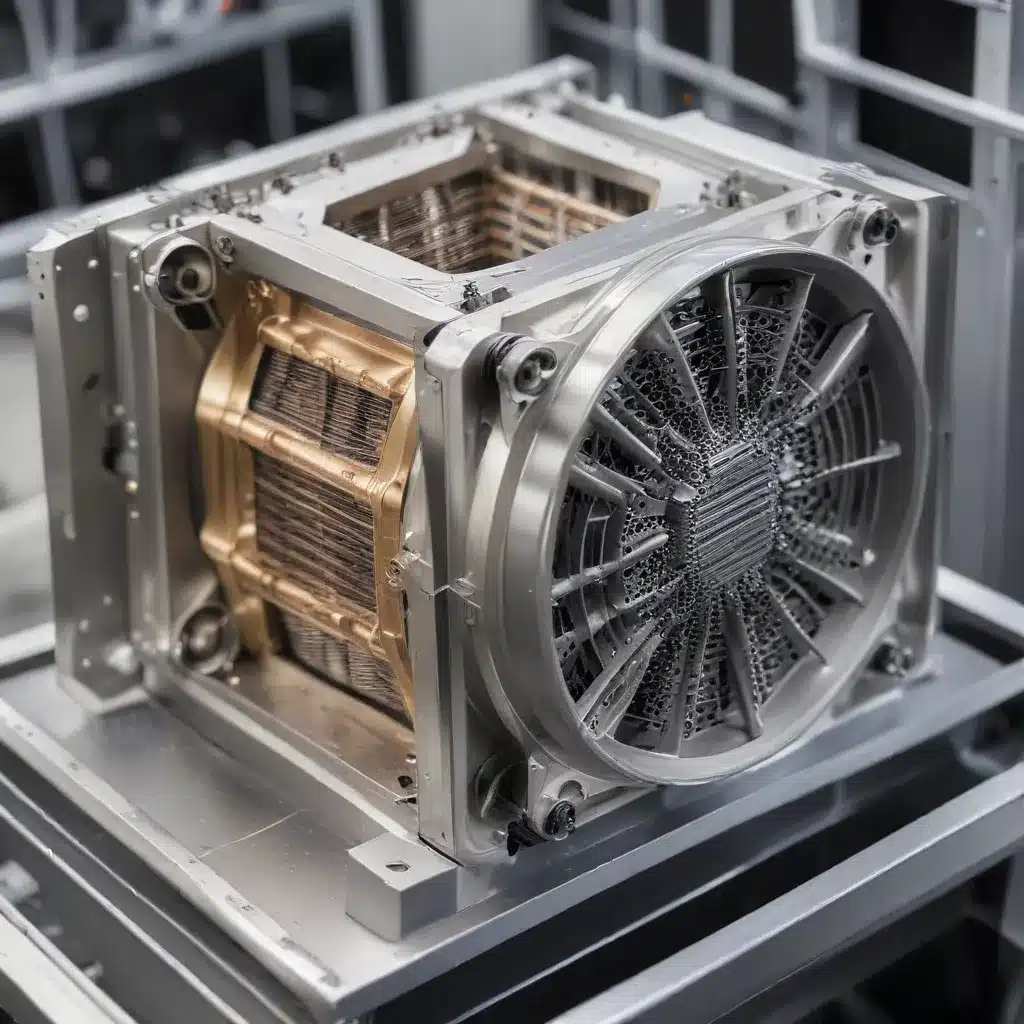

In the realm of additive manufacturing (AM), the design freedom and manufacturing capabilities afforded by 3D printing have unlocked new possibilities for air-cooled HEXs. By leveraging the unique advantages of AM, engineers can now create heat exchangers with unprecedented performance, compactness, and reliability – characteristics that are crucial for applications where thermal management is a make-or-break factor.

In this comprehensive article, we will delve into the innovative thermal management capabilities of air-cooled HEXs in the context of additive manufacturing. We will explore the design principles, material considerations, and optimization strategies that enable these advanced heat exchangers to excel in demanding environments, from aerospace and automotive to electronics and beyond.

Maximizing Heat Transfer Performance with Additive Manufacturing

The ability to dissipate excess heat is a fundamental requirement for the successful operation of numerous systems and devices. Traditional manufacturing methods have long been the go-to approach for fabricating heat exchangers, but they often fall short in meeting the ever-increasing demands for higher performance, smaller size, and greater design flexibility.

Additive manufacturing has emerged as a game-changer in this realm, unlocking new possibilities for air-cooled HEX design and optimization. By leveraging the design freedom afforded by 3D printing, engineers can now create intricate internal geometries and complex surface features that are simply not feasible with conventional manufacturing techniques.

One of the key advantages of AM in HEX design is the ability to incorporate lattice structures, such as Triply Periodic Minimal Surface (TPMS) lattices. These intricate, bionic-inspired geometries offer a remarkable surface area-to-volume ratio, enabling significantly higher heat transfer rates within a compact footprint. The gyroid and diamond TPMS lattices, in particular, have proven to be highly effective in separating fluid flows and maximizing heat exchange efficiency.

“Lattice structures are commonly found in nature. The honeycomb pattern in beehives and repeating patterns in tree trunks are just two examples of lattice structures. These structures utilize the space around them to create complex shapes that traditional manufacturing methods often cannot fabricate.”

By leveraging the design freedom of additive manufacturing, engineers can tailor the internal geometry of air-cooled HEXs to optimize flow patterns, minimize pressure drop, and enhance overall thermal performance. This level of customization and optimization simply cannot be achieved through conventional manufacturing methods, making AM a transformative technology in the world of thermal management.

Addressing Size, Weight, and Integration Challenges with Additive Manufacturing

In many industries, particularly aerospace and automotive, size and weight constraints are critical factors that must be carefully considered in the design of thermal management systems. Traditional heat exchangers often struggle to meet these stringent requirements, as their conventional designs and manufacturing limitations can result in bulky and heavy components.

Additive manufacturing offers a solution to these challenges by enabling the creation of more compact and lightweight air-cooled HEXs. The design freedom of AM allows engineers to explore innovative geometries and morphologies that are tailored to fit the available space, seamlessly integrating the heat exchanger into the overall system architecture.

For example, the ability to create intricate internal channels and complex surface features with AM can lead to a significant reduction in the overall size and weight of the HEX without compromising its thermal performance. This is particularly advantageous in applications where space is limited, such as in electric vehicles, where efficient cooling of batteries and power electronics is crucial for extended range and reliable operation.

Furthermore, the monolithic design approach facilitated by additive manufacturing can eliminate the need for multiple components and assembly, further reducing weight and streamlining the overall system. By consolidating the HEX into a single, optimized part, the potential for leaks and failure points is minimized, enhancing the reliability and durability of the thermal management system.

“Additive manufacturing allows you to reduce weight while preserving overall strength and structural integrity. This means heat exchanger designs can perform in demanding environments.”

As the aerospace industry continues to push the boundaries of innovation, the ability to create lightweight, high-performance air-cooled HEXs through additive manufacturing has become increasingly valuable. From enabling efficient thermal management in electric vertical take-off and landing (eVTOL) aircraft to ensuring the reliability of sensitive electronics in spacecraft, the advancements in AM-based thermal solutions are shaping the future of air and space travel.

Overcoming Material Challenges with Additive Manufacturing

The choice of materials is a critical consideration in the design and fabrication of air-cooled heat exchangers, as the thermal conductivity, strength, and corrosion resistance of the chosen material can have a significant impact on the overall performance and durability of the HEX.

Traditional manufacturing methods have long relied on commonly available materials, such as aluminum and copper, to create heat exchangers. However, the design freedom and manufacturing capabilities of additive technology have opened up new avenues for material exploration and optimization.

One material that has garnered particular interest in the realm of AM-based HEXs is pure copper. Renowned for its exceptional thermal conductivity, copper is an ideal choice for applications that demand efficient heat dissipation. However, the material’s reflective properties and the challenge of maintaining a well-defined melt pool during the AM process have posed challenges in the past.

“Copper is a potential material for heat exchanger design. Pure copper has excellent thermal conductivity, making it ideal for diffusing heat in various applications — from microelectronics to injection molding tool inserts. However, this property makes maintaining a neatly defined melt pool complex in MPBF processes.”

Advances in additive manufacturing technology and the development of specialized design engineering software have helped overcome these hurdles, paving the way for the successful integration of copper in the fabrication of high-performance air-cooled HEXs. By carefully optimizing the AM process parameters and leveraging advanced simulation tools, engineers can now create copper-based heat exchangers that harness the material’s superior thermal properties to deliver unparalleled thermal management capabilities.

Aluminum, on the other hand, has long been a popular choice for heat exchanger components due to its favorable combination of high thermal conductivity and low density. The inherent advantages of aluminum make it particularly well-suited for applications where weight is a critical factor, such as in the aerospace and automotive industries.

Additive manufacturing has further enhanced the appeal of aluminum-based air-cooled HEXs by enabling the creation of intricate geometries and lightweight structures that were previously unattainable through traditional manufacturing methods. This, in turn, has led to the development of innovative heat exchanger designs that deliver exceptional thermal performance while reducing overall weight and size.

Unlocking the Design Potential of Air-Cooled Heat Exchangers with Additive Manufacturing

The design freedom and manufacturing capabilities of additive technology have fundamentally transformed the way engineers approach the development of air-cooled heat exchangers. By leveraging the unique advantages of AM, designers can now create HEXs that far exceed the performance and functionality of their traditional counterparts.

One of the key innovations in this realm is the use of advanced lattice structures, such as TPMS lattices, to form the core of the heat exchanger. These bionic-inspired geometries offer a remarkable surface area-to-volume ratio, enabling significantly higher heat transfer rates within a compact footprint. The gyroid and diamond TPMS lattices, in particular, have proven to be highly effective in separating fluid flows and optimizing heat exchange efficiency.

“TPMS structures naturally separate two-liquid flows, provide a large surface area for heat transfer, and conform to the available design space. Additionally, these structures are self-supporting, easily manufacturable, and naturally separate the flow into two domains.”

Furthermore, the design freedom afforded by additive manufacturing allows engineers to optimize the inlet and outlet plenums, as well as the distribution of flow within the heat exchanger core. By leveraging computational fluid dynamics (CFD) simulations and field-driven design approaches, designers can create tailored geometries that minimize pressure drops and ensure even flow distribution, ultimately enhancing the overall thermal performance of the air-cooled HEX.

The integration of additive manufacturing with advanced engineering design software, such as nTop, has been instrumental in unlocking the true potential of air-cooled heat exchangers. These innovative tools enable designers to seamlessly incorporate simulation data into the design process, allowing them to generate highly optimized geometries that meet the specific thermal management requirements of their applications.

“With advanced engineering design software, you can now use simulations as an input that drives key variables to generate your design. This involves inverting the classical approach to simulation by first running a simulation to reveal the flow direction inside your heat exchanger and then creating a geometry around it.”

By leveraging the design freedom and manufacturing capabilities of additive technology, engineers can create air-cooled heat exchangers that are not only more compact and lightweight but also significantly more efficient and reliable. These advancements in thermal management solutions are paving the way for groundbreaking innovations across a wide range of industries, from aerospace and automotive to electronics and beyond.

Conclusion: Unlocking the Future of Thermal Management with Additive Air-Cooled Heat Exchangers

As technological advancements continue to push the boundaries of innovation, the role of air-cooled heat exchangers in thermal management has never been more critical. Additive manufacturing has emerged as a transformative technology in this domain, unlocking new possibilities for the design and fabrication of high-performance, compact, and reliable HEXs.

By leveraging the design freedom and manufacturing capabilities of AM, engineers can now create air-cooled heat exchangers that exceed the limitations of traditional manufacturing methods. From incorporating advanced lattice structures to optimizing flow patterns and material selection, the advancements in additive-based thermal management solutions are paving the way for groundbreaking innovations across a wide range of industries.

As the demand for efficient and compact thermal management systems continues to grow, the adoption of additive manufacturing for the development of air-cooled heat exchangers will undoubtedly play a pivotal role in shaping the future of thermal management. By empowering designers with the tools and capabilities to create truly innovative HEX designs, the https://www.aircooledheatexchangers.net/ community is at the forefront of this technological revolution, driving sustainable and efficient thermal solutions for a wide array of applications.