The Significance and Challenges of Chemical Vapor Infiltration

Chemical vapor infiltration (CVI) is a widely adopted manufacturing technique used in producing carbon-carbon (C/C) and carbon-silicon carbide (C/SiC) composites. These materials are especially valued in the aerospace and automotive industries for their robust strength and lightweight characteristics. The densification process during CVI critically influences the final performance, quality, and consistency of these composite materials.

Experimentally optimizing the CVI processes is challenging due to the long experimental time and large optimization space. The isothermal CVI (I-CVI) variant, in particular, can last for months, rendering conventional trial-and-error approaches infeasible. This necessitates the creation of a predictive model that enables efficient computer-based simulations, offering the potential for markedly reduced turnover times and allowing for a comprehensive exploration of varied manufacturing conditions.

However, existing numerical models for the I-CVI process often rely on multiple assumptions due to unresolved or unknown physical phenomena, compromising their accuracy and reliability. Moreover, the development and simulation of these models demand substantial computational resources, restricting their immediate applicability for optimization and uncertainty assessments.

To effectively simulate and optimize the I-CVI process, the creation of a new modeling framework that is both generally applicable and scalable is indispensable. The growing availability of data offers promising avenues for machine learning (ML)-based, data-driven modeling techniques to make substantial advancements in this regard.

The Potential of Physics-Integrated Neural Differentiable Modeling

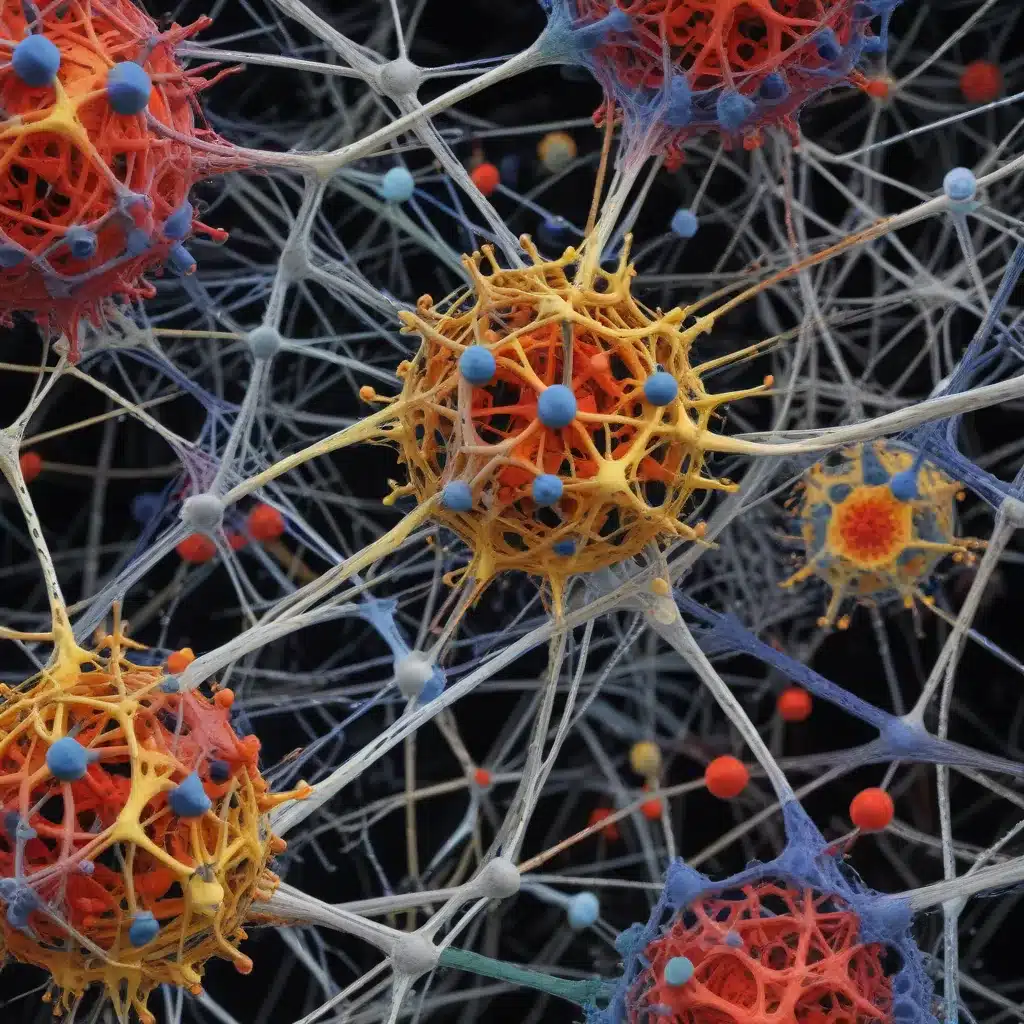

Deep neural networks (DNNs), cornerstones of ML, have long been recognized for their efficacy in diverse fields, ranging from speech recognition and image analysis to natural language processing. Harnessing the rapid advancements in computational resources and algorithmic developments, along with a vast accumulation of experimental and simulation data, DNNs have been established as essential tools in the domain of scientific machine learning (SciML), which is progressively being adopted in composite manufacturing prediction and optimization.

However, pure data-driven DNN methods have been limited in their use for modeling the CVI process due to the substantial data requirement and restricted generalizability of these models beyond their training regimes. To address these challenges, the physics-informed deep learning (PIDL) strategy, leveraging physics principles to enhance the design, training, or inference of DNNs, presents a promising potential solution.

One notable PIDL method is the physics-informed neural network (PINN), wherein the governing equations are incorporated into the loss function to regularize the training process, thereby reducing the required labeled data. However, the introduction of nonlinearity into the loss function can pose significant challenges in optimization, and the physics-based loss function requires complete governing equations of the underlying physics, which are not available for the intricate I-CVI processes.

To integrate incomplete physics with deep learning, the hybrid differentiable neural modeling emerges as a notable alternative PIDL method, which fuses physics-derived mathematical models with the robust learning capability of neural networks, ensuring efficient learning even with limited data. Differentiable programming (DP) serves as a cornerstone in this framework, allowing for the joint optimization of both DNNs and physics-centric components within a unified training environment.

The development of differentiable physics solvers and hybrid neural models has recently gained traction, exemplifying their adaptability across various scientific fields. Notably, the physics-integrated neural differentiable (PiNDiff) framework, introduced by Akhare et al., seamlessly integrates partially-known physics into neural networks while preserving the mathematical integrity of governing equations through DP.

Constructing the PiNDiff I-CVI Model

Driven by the potential of the PiNDiff framework, our objective in this work is to employ it to develop a predictive model for the I-CVI process in fabricating C/C composites, highlighting its ability to work with partially-known physics and sparse indirect measurements.

Extending from the original PiNDiff formulation, our study broadens its scope to the I-CVI process, which is governed by both hyperbolic and elliptic partial differential equations (PDEs). A primary thrust of this effort is to distill the existing physics-based model into a more concise PDE system that serves as the physics-based backbone of the PiNDiff model.

Based on this simplified PDE system and utilizing the differential hybrid methodology, we construct a network to build a predictive model for the I-CVI process. However, this simplification, along with the potential over-parameterization of neural operator components, may introduce errors in predictions. To address this issue, we extend the PiNDiff framework by integrating uncertainty quantification (UQ) features, utilizing Deep Ensemble (DeepEn) techniques.

The PiNDiff I-CVI model incorporates three different neural networks to capture the unknown operators: effective diffusion coefficient (Deff), reaction rate (K), and effective surface area (Sv). These operators are seamlessly integrated with the distilled PDE system to form the predictive model.

Evaluating the PiNDiff I-CVI Model

To evaluate the model’s capability in inferring these unknown fields from indirect mass measurements, we conducted a set of synthetic experiments. In each experiment, one of the operators (Deff, K, or Sv) was treated as unknown and to be inferred with its corresponding neural network, while the representations for the other two operators were provided based on the “ground truth” model.

The PiNDiff model’s predicted mass growth aligned well with the synthetic data across all three cases, and the trained model was able to accurately capture the spatio-temporal dynamics of both the unknown parameters and state variables, just from the mass growth data points.

Furthermore, the model provided a quantification of the uncertainty associated with each prediction, demonstrating its resilience in the face of incomplete physics knowledge.

An extended investigation was conducted where the functional forms of all three operators, Deff, K, and Sv, were treated as unknown and trained using the same dataset. Although the predictions for mass remained accurate, the inferred mean values for the hidden states and parameters exhibited a slight deviation from the previous synthetic experiments. However, the model’s uncertainty in its predictions was elevated, indicating a reduced confidence in its predictions when faced with a diminished extent of known physics.

To assess the model’s generalizability across different input parameters, we trained it using synthetic data generated from a diverse range of operating conditions and subsequently validated it against different sets of unseen operating conditions. The results demonstrated the model’s excellent predictive capability, with its estimations closely matching the projected mass evolution across a span of 350 hours for each preform section. Additionally, the model adeptly inferred the spatio-temporal trajectories of porosity, molarity, effective diffusion coefficient, and effective deposition rate, with the confidence interval provided by the model adequately encompassing the ground truth.

Extending the PiNDiff I-CVI Model to Real-World Applications

Obtaining detailed measurement data by segmenting multiple C/C composite samples during the manufacturing process can be labor-intensive and often impractical. Building upon our earlier study, we focused on assessing the model’s ability to generalize within the input operating parameter space using only the total mass data from the entire unsegmented composite sample.

Despite the less accurate inferences for Deff and Sv, the spatio-temporal behavior of the porosity and molarity remained plausible, which can be credited to the PiNDiff model’s inherent capability of maintaining the mathematical structure of the physics-derived models. Furthermore, the model’s uncertainty predictions for molarity and porosity were both reasonable and inclusive of the ground truth, demonstrating the model’s resilience even when faced with limited and less descriptive data.

The PiNDiff I-CVI model was further evaluated using real experimental data from Benzinger and Huttinger’s work on the I-CVI densification process. The model’s predictions exhibited excellent alignment with the real data for both training and testing partial pressures, attesting to the learning and predictive capability of the proposed model. Moreover, the model’s uncertainty predictions were higher in regions where the training data were absent, suggesting diminished confidence in the model’s predictions in those specific regions.

Finally, we explored the model’s inference capability in a more realistic manufacturing setting, focusing on the iterative I-CVI and machining cycles adopted by Honeywell in their C/C composite brake manufacturing protocol. The PiNDiff model successfully captured the evolution of the densification process throughout the manufacturing phase, offering spatio-temporal forecasts of porosity, an indispensable parameter for optimization endeavors.

Conclusion

This study presents the development and assessment of a physics-integrated neural differentiable model for I-CVI processes, the PiNDiff I-CVI model. By seamlessly integrating the partially known physics into a deep learning framework, the PiNDiff model has established itself as an effective modeling framework for the I-CVI process, showcasing its competency even when reliant on limited, indirect training datasets.

The PiNDiff I-CVI model has been thoroughly evaluated through a series of synthetic experiments and tests, confirming its effectiveness and capabilities in accurately predicting mass deposition and inferring the spatio-temporal fields of key parameters. Notably, the model’s ability to encapsulate and quantify uncertainties has been a crucial feature, particularly when confronted with incomplete physics and scarce data.

The model’s performance has also been validated using real experimental data, as well as data from Honeywell’s manufacturing processes, reaffirming its effectiveness and ability in predictive modeling of the I-CVI processes. The results highlight the model’s potential to support process optimization and decision-making tasks, emphasizing its practical applicability in real-world scenarios.

In conclusion, the PiNDiff I-CVI model proves to be a valuable tool for understanding, simulating, and predicting the I-CVI densification process, offering a promising approach for advancing the manufacturing of carbon-based composites to enhance their performance and quality.

Acknowledgments

The authors would like to acknowledge the funds from the Air Force Office of Scientific Research (AFOSR), United States of America, under award number FA9550-22-1-0065. J.X.W. would also like to acknowledge the funding support from the Office of Naval Research under award number N00014-23-1-2071 and the National Science Foundation under award number OAC-2047127 in supporting this study.