Unlocking the Secrets of Li-ion Battery Thermal Management

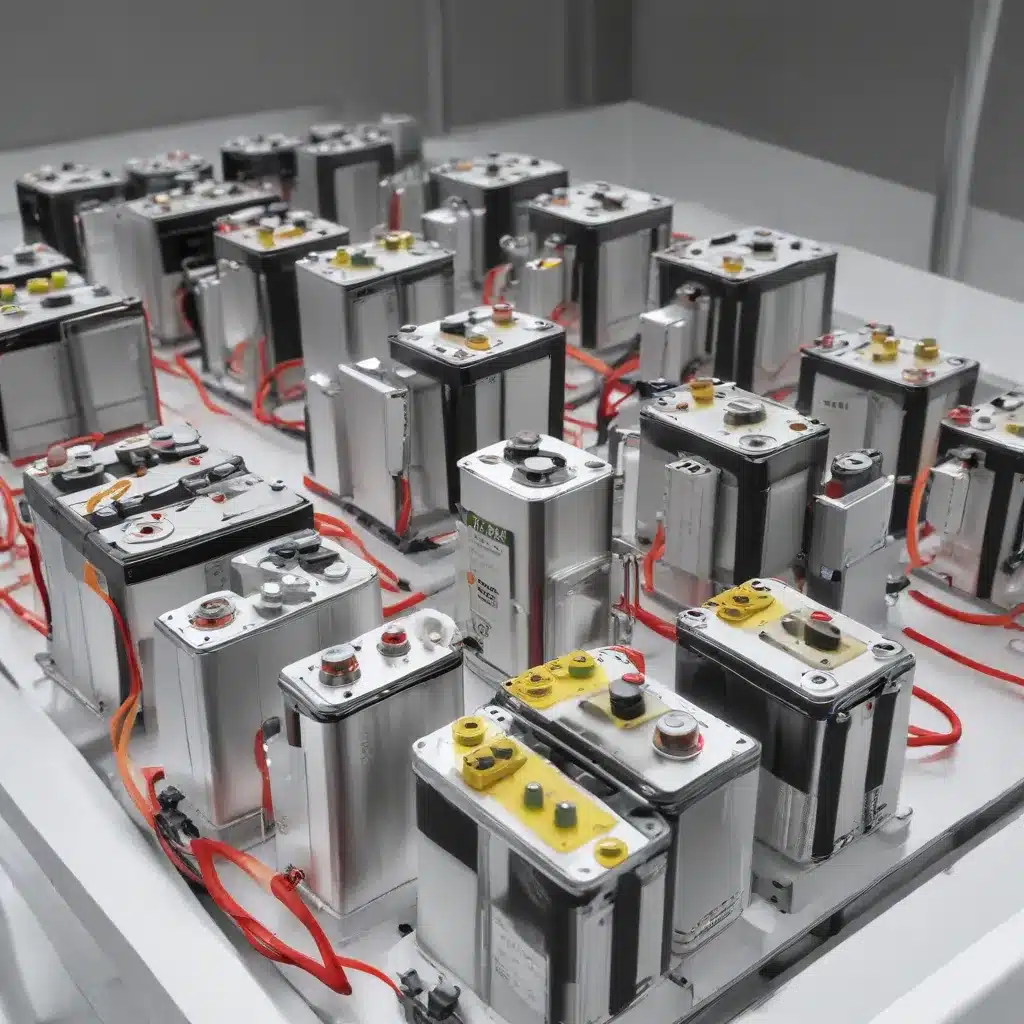

As the world continues its relentless march towards electrification, the demand for efficient and reliable energy storage solutions has never been greater. Among the frontrunners in this field, lithium-ion (Li-ion) batteries have emerged as the technology of choice, powering everything from electric vehicles to renewable energy systems. However, the very nature of these high-energy batteries presents a unique challenge: thermal management.

Effective thermal regulation is paramount for ensuring the safety, longevity, and optimal performance of Li-ion batteries. Overheating can lead to catastrophic failures, while improper cooling can result in reduced capacity, accelerated degradation, and even catastrophic thermal runaway events. This is where the role of air-cooled heat exchangers becomes increasingly crucial in the realm of Li-ion battery thermal management.

In this comprehensive article, we will delve into the experimental exploration of thermal regulation in Li-ion batteries using calorimetry. We’ll uncover the latest insights, practical tips, and industry-leading strategies to ensure your Li-ion battery systems operate at their peak, no matter the application.

Understanding the Thermal Challenges of Li-ion Batteries

Li-ion batteries are inherently complex systems, with a delicate balance of electrochemical reactions, mechanical stresses, and thermal dynamics at play. During the charging and discharging processes, these batteries generate significant amounts of heat, which must be effectively dissipated to maintain optimal operating conditions.

The key thermal challenges associated with Li-ion batteries include:

-

Heat Generation: Li-ion batteries generate heat during both charging and discharging cycles due to various electrochemical and physical processes, such as charge transport, phase changes, and side reactions.

-

Thermal Runaway: When Li-ion batteries overheat, they can enter a state of thermal runaway, a self-sustaining exothermic reaction that can lead to fire, explosion, and catastrophic failure.

-

Capacity Degradation: Elevated temperatures can accelerate the degradation of Li-ion battery components, leading to a gradual loss of capacity and reduced cycle life.

-

Safety Concerns: Uncontrolled heating in Li-ion batteries can pose serious safety risks, including the release of flammable gases and the potential for thermal propagation across battery packs.

To address these challenges, researchers and engineers have explored various cooling strategies, including air-cooled heat exchangers, which offer a practical and cost-effective solution for thermal management in Li-ion battery systems.

Calorimetry: The Key to Understanding Li-ion Battery Thermal Behavior

Calorimetry, the scientific study of the heat generated or absorbed during chemical and physical processes, has emerged as a powerful tool for understanding the thermal behavior of Li-ion batteries. By employing calorimetric techniques, researchers can gain invaluable insights into the complex thermal dynamics within these energy storage systems.

One of the most commonly used calorimetric methods in Li-ion battery research is accelerating rate calorimetry (ARC). ARC allows for the measurement of the heat generation rate and thermal runaway characteristics of Li-ion batteries under controlled conditions, providing crucial data for the design of effective thermal management systems.

Another widely adopted calorimetric technique is differential scanning calorimetry (DSC). DSC enables the measurement of the heat flow associated with phase changes, chemical reactions, and other thermal events within Li-ion batteries, shedding light on the underlying thermal mechanisms.

By leveraging these calorimetric techniques, researchers can:

-

Quantify Heat Generation: Accurately measure the heat generated by Li-ion batteries during charge, discharge, and abuse conditions to inform the design of cooling systems.

-

Identify Thermal Runaway Triggers: Determine the onset temperatures and kinetics of thermal runaway, allowing for the development of proactive safety measures.

-

Optimize Battery Chemistry: Evaluate the thermal stability and performance of different battery chemistries and materials to guide the selection of optimal components.

-

Assess Degradation Mechanisms: Investigate the impact of aging, cycling, and environmental factors on the thermal behavior of Li-ion batteries, informing maintenance and lifetime prediction strategies.

The insights gained from calorimetric studies have been instrumental in advancing the field of Li-ion battery thermal management, paving the way for innovative cooling solutions that ensure the safe and reliable operation of these critical energy storage systems.

Exploring Air-Cooled Heat Exchangers for Li-ion Battery Thermal Management

Air-cooled heat exchangers have emerged as a versatile and cost-effective solution for managing the thermal challenges of Li-ion batteries. These heat exchangers leverage the principles of convective heat transfer to dissipate the generated heat, maintaining the batteries within their optimal operating temperature range.

One of the key advantages of air-cooled heat exchangers is their simplicity and ease of integration into Li-ion battery systems. Unlike liquid-based cooling systems, air-cooled solutions do not require complex plumbing, pumps, or coolant management, making them an attractive option for a wide range of applications, from electric vehicles to stationary energy storage.

In a recent study published in the Journal of Renewable Energy and Environment, researchers explored the experimental evaluation of combining air-cooled heat exchangers with various active and passive cooling methods for Li-ion battery thermal management. The study revealed several valuable insights:

-

Direct Refrigerant Contact: The researchers employed a direct contact approach, where the refrigerant was allowed to directly contact the battery cells. This novel technique effectively reduced the cells’ maximum temperature by up to 34°C, demonstrating the potential of leveraging phase-change cooling for enhanced thermal regulation.

-

Passive Cooling Enhancements: The team investigated the use of hydrogel between the fins of the air-cooled heat exchanger as a passive cooling method. This approach resulted in a modest but noteworthy reduction of 0.5°C in the cells’ maximum temperature, highlighting the value of incorporating passive cooling strategies.

-

Active Cooling Integration: The researchers also combined the air-cooled heat exchanger with an active forced liquid cooling system, exploring the impact of different water flow rates and inlet temperatures. At a flow rate of 200 LPH, the cells’ maximum temperature was reduced by 1.5°C compared to the mode without forced water flow, demonstrating the synergistic benefits of integrating active and passive cooling approaches.

These experimental findings underscore the versatility and effectiveness of air-cooled heat exchangers in addressing the thermal management challenges of Li-ion batteries. By combining multiple cooling strategies, researchers can optimize the thermal performance of these energy storage systems, ensuring their safety, reliability, and longevity.

Optimizing Air-Cooled Heat Exchanger Design for Li-ion Battery Applications

As the demand for Li-ion battery-powered applications continues to grow, the design and optimization of air-cooled heat exchangers have become increasingly crucial. Engineers and designers must consider a multitude of factors to ensure the optimal thermal management of these energy storage systems.

Some key considerations in the design of air-cooled heat exchangers for Li-ion batteries include:

-

Heat Transfer Coefficient Optimization: Enhancing the convective heat transfer coefficient between the air and the heat exchanger surfaces is crucial for efficient heat dissipation. This can be achieved through innovative fin designs, optimized airflow patterns, and the strategic placement of the heat exchanger within the battery pack.

-

Airflow Distribution: Ensuring uniform and efficient airflow distribution across the battery pack is essential for maintaining consistent cooling and preventing hot spots. Computational fluid dynamics (CFD) simulations can be leveraged to model and optimize the airflow patterns within the system.

-

Thermal Interface Materials: The selection and integration of high-performance thermal interface materials, such as thermal greases or phase-change materials, can significantly improve the thermal contact between the battery cells and the heat exchanger, enhancing heat transfer.

-

Modularity and Scalability: Designing air-cooled heat exchangers with modular and scalable architectures allows for easy integration into a wide range of Li-ion battery systems, from small portable devices to large-scale energy storage installations.

-

Noise and Vibration Considerations: In applications where noise and vibration are critical factors, such as electric vehicles, the design of the air-cooled heat exchanger must account for these parameters to ensure a comfortable and reliable user experience.

By meticulously addressing these design considerations, engineers can develop air-cooled heat exchangers that effectively manage the thermal challenges of Li-ion batteries, enabling the safe, efficient, and long-lasting operation of these essential energy storage solutions.

Maintenance and Optimization of Air-Cooled Heat Exchangers for Li-ion Batteries

Proper maintenance and optimization of air-cooled heat exchangers are crucial for ensuring the continued reliable performance of Li-ion battery systems. Regular inspection and proactive maintenance can extend the lifespan of these critical cooling components and help maintain the overall health and safety of the battery pack.

Some key maintenance and optimization strategies for air-cooled heat exchangers in Li-ion battery applications include:

-

Periodic Cleaning: Regularly cleaning the heat exchanger fins and surfaces to remove any accumulated dust, debris, or contaminants that can impede airflow and reduce heat transfer efficiency.

-

Airflow Monitoring: Implementing sensors and monitoring systems to track the airflow through the heat exchanger and detect any blockages or obstructions that may compromise the cooling performance.

-

Preventive Maintenance: Scheduling routine inspections and maintenance tasks, such as checking for corrosion, wear, and degradation of components, to identify and address any issues before they become critical.

-

Airflow Optimization: Continuously evaluating and optimizing the airflow patterns within the battery pack, adjusting the heat exchanger placement, fan speeds, and other parameters to maintain optimal cooling performance.

-

Performance Audits: Conducting periodic performance audits, which may involve calorimetric testing or thermal imaging, to assess the heat dissipation capabilities of the air-cooled heat exchanger and identify any areas for improvement.

-

Predictive Maintenance: Leveraging advanced analytics and machine learning techniques to predict the remaining useful life of the air-cooled heat exchanger and plan maintenance activities accordingly, minimizing unplanned downtime and ensuring continuous reliable operation.

By diligently implementing these maintenance and optimization strategies, Li-ion battery system operators can ensure the optimal performance and longevity of their air-cooled heat exchangers, contributing to the overall safety, efficiency, and sustainability of their energy storage solutions.

Conclusion: Embracing the Future of Li-ion Battery Thermal Management

As the world continues its transition towards electrification and renewable energy, the role of Li-ion batteries in powering this transformation has become increasingly crucial. Effective thermal management, leveraging the capabilities of air-cooled heat exchangers, is essential for unlocking the full potential of these energy storage technologies.

Through the experimental exploration of thermal regulation using calorimetry, researchers and engineers have gained invaluable insights into the complex thermal dynamics of Li-ion batteries. These findings have paved the way for the development of innovative cooling solutions that seamlessly integrate air-cooled heat exchangers, combining passive and active cooling strategies to ensure the safe, reliable, and efficient operation of these critical energy systems.

By optimizing the design, maintenance, and performance of air-cooled heat exchangers, the Air Cooled Heat Exchangers team is committed to empowering the next generation of Li-ion battery applications, from electric vehicles to renewable energy storage. As the demand for sustainable energy solutions continues to grow, the role of air-cooled heat exchangers in thermal management will only become more vital, ensuring the reliable and safe operation of these essential technologies for a brighter, more energy-efficient future.