As a seasoned expert in the field of air-cooled heat exchangers, I’m excited to share my insights and practical tips on how these remarkable thermal management solutions can be leveraged across various industries. In this comprehensive article, we’ll delve into the design, engineering, maintenance, performance optimization, and diverse applications of air-cooled heat exchangers, empowering you with the knowledge to harness their full potential.

Understanding the Fundamentals of Air-Cooled Heat Exchangers

At their core, air-cooled heat exchangers are engineered to efficiently transfer heat from one fluid (typically a liquid or gas) to another, using air as the cooling medium. This elegantly simple yet highly effective approach to thermal management has made air-cooled heat exchangers a staple in a wide range of industries, including power generation, HVAC, manufacturing, and petrochemical processing, among others.

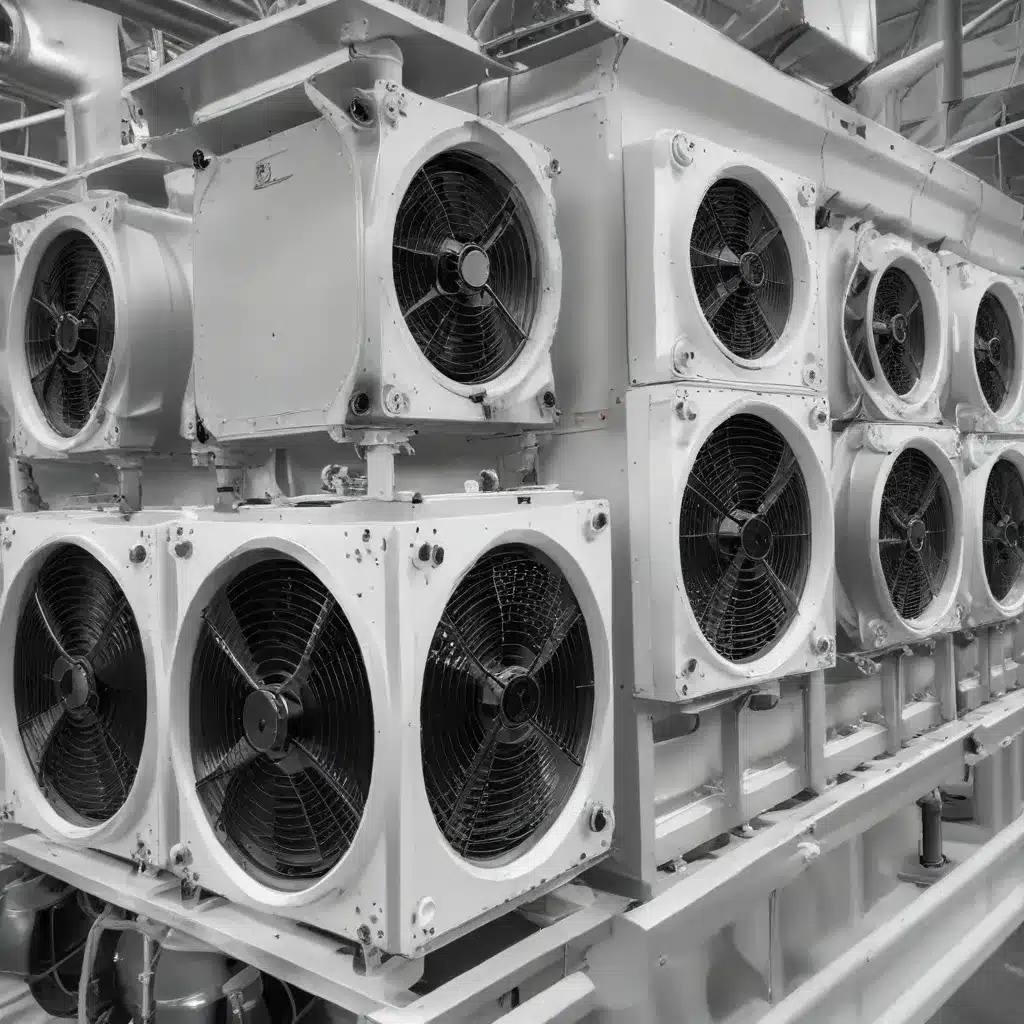

The key to the success of air-cooled heat exchangers lies in their innovative design. These devices feature a network of metal tubes or fins, through which the hot fluid (e.g., water, oil, or refrigerant) flows. Surrounding this heat transfer surface is a forced air stream, typically generated by one or more fans, which absorbs the heat from the fluid and dissipates it into the ambient environment.

This elegant and straightforward approach to heat exchange offers a host of advantages that have made air-cooled heat exchangers a preferred choice in many applications:

- Versatility: Air-cooled heat exchangers can be designed to accommodate a broad range of fluid types, flow rates, and temperature requirements, making them suitable for diverse industrial and commercial applications.

- Reliability: With relatively few moving parts, air-cooled heat exchangers are known for their robust construction and low maintenance requirements, ensuring reliable performance over extended periods.

- Energy Efficiency: By leveraging the natural convective properties of air, air-cooled heat exchangers can often achieve comparable thermal performance to their water-cooled counterparts while consuming less energy for the cooling process.

- Reduced Water Consumption: In regions with limited water resources or where water conservation is a priority, air-cooled heat exchangers provide a sustainable alternative to water-cooled systems, eliminating the need for significant water withdrawal or consumption.

- Compact Design: The use of air as the cooling medium allows air-cooled heat exchangers to be designed in a relatively compact footprint, making them well-suited for installations with space constraints.

Designing for Optimal Performance

Maximizing the thermal management capabilities of air-cooled heat exchangers requires a deep understanding of the underlying design principles and engineering considerations. Let’s explore some of the key factors that contribute to the performance optimization of these heat transfer solutions.

Tube and Fin Configuration

The design of the heat transfer surfaces, including the tube arrangement and fin geometry, plays a crucial role in the overall efficiency of an air-cooled heat exchanger. Engineers often experiment with various tube configurations, such as staggered or in-line arrangements, to enhance turbulence and improve heat transfer rates. Similarly, the choice of fin type (e.g., plate fins, serrated fins, or louvered fins) and their design parameters can significantly impact the heat exchanger’s performance.

Airflow Optimization

Efficient airflow management is essential for maximizing the heat transfer capabilities of air-cooled heat exchangers. Factors such as fan selection, air inlet and outlet design, and the incorporation of flow-guiding structures can all contribute to optimizing the air velocity and distribution across the heat transfer surfaces.

Material Selection

The choice of materials used in the construction of air-cooled heat exchangers can have a significant impact on their durability, corrosion resistance, and overall thermal performance. Common materials include aluminum, copper, and stainless steel, each with its own unique properties and suitability for different operating environments.

Thermal Analysis and Modeling

Leveraging advanced computational fluid dynamics (CFD) simulations and thermal modeling techniques can provide valuable insights into the heat transfer characteristics of air-cooled heat exchangers. These analytical tools allow engineers to optimize the design, predict performance, and identify potential areas for improvement before the physical fabrication of the heat exchanger.

Maintenance and Troubleshooting Strategies

Maintaining the peak performance of air-cooled heat exchangers is crucial for ensuring their reliability and longevity. As an experienced expert, I’ve compiled a set of best practices and troubleshooting strategies to help you keep your air-cooled heat exchangers running at their best.

Routine Inspections and Cleaning

Regular visual inspections and cleaning of the heat transfer surfaces, air inlets, and fans can help identify and address potential issues before they escalate. Removing debris, dirt, and other contaminants that can accumulate over time ensures optimal airflow and heat transfer efficiency.

Monitoring and Preventive Maintenance

Establishing a comprehensive preventive maintenance program that includes regular monitoring of key performance indicators, such as pressure drop, air velocity, and fluid temperatures, can help detect any emerging problems early on. Proactive maintenance, such as timely fan motor replacements or fin straightening, can extend the service life of air-cooled heat exchangers.

Troubleshooting Common Issues

Air-cooled heat exchangers may occasionally encounter a range of issues, including reduced heat transfer, increased pressure drop, or fan malfunctions. By systematically analyzing the symptoms, examining the underlying causes, and implementing appropriate corrective actions, you can quickly resolve these problems and restore optimal performance.

Upgrade and Retrofit Opportunities

As technology advances and industry demands evolve, there may be instances where upgrading or retrofitting existing air-cooled heat exchangers can significantly enhance their thermal management capabilities. Exploring options like fin coatings, fan upgrades, or the incorporation of advanced control systems can help you future-proof your heat exchanger assets.

Applications and Case Studies

Air-cooled heat exchangers have found widespread adoption across a diverse range of industries, showcasing their versatility and problem-solving capabilities. Let’s explore a few compelling case studies that highlight the impact of these thermal management solutions.

Power Generation

In the power generation industry, air-cooled heat exchangers play a crucial role in cooling critical components, such as generator stators, transformer oils, and lubricating fluids. By effectively dissipating the heat generated by these high-intensity systems, air-cooled heat exchangers help maintain optimal operating temperatures, improve efficiency, and extend the service life of power generation equipment.

HVAC Systems

Air-cooled heat exchangers are integral to the design of modern HVAC systems, serving as the primary heat rejection device in air-conditioning and refrigeration applications. Their ability to efficiently transfer heat from the refrigerant or cooling fluid to the surrounding air makes them an essential component in maintaining comfortable indoor environments, especially in regions with temperate or hot climates.

Manufacturing Processes

Across various manufacturing industries, air-cooled heat exchangers are employed to manage the thermal loads generated by equipment, such as compressors, welding stations, and metal-working machinery. By ensuring the proper cooling of these critical components, air-cooled heat exchangers help maintain process efficiency, product quality, and equipment longevity.

Renewable Energy Systems

In the renewable energy sector, air-cooled heat exchangers play a vital role in the thermal management of solar photovoltaic (PV) systems and wind turbines. By effectively dissipating the heat generated by these clean energy technologies, air-cooled heat exchangers help optimize their performance and extend their operational lifespans, contributing to the overall sustainability and viability of renewable energy solutions.

These case studies showcase the versatility and problem-solving capabilities of air-cooled heat exchangers, underscoring their importance in various industries. As technology continues to evolve and industry demands become more complex, the role of these thermal management solutions will only grow more crucial.

Embracing the Future of Air-Cooled Heat Exchanger Technology

As we look to the future, the thermal management capabilities of air-cooled heat exchangers will become increasingly pivotal in addressing the growing challenges faced by industries worldwide. Trends such as the push for greater energy efficiency, the need for sustainable cooling solutions, and the integration of advanced control systems will shape the evolution of air-cooled heat exchanger technology.

One promising area of development is the integration of additive manufacturing (3D printing) techniques in the production of air-cooled heat exchangers. This innovative approach allows for the creation of complex fin geometries and intricate flow paths, unlocking new levels of heat transfer optimization and customization to meet the unique requirements of specific applications.

Furthermore, the incorporation of smart sensors, predictive maintenance algorithms, and advanced controls can transform air-cooled heat exchangers into intelligent, self-monitoring systems. By continuously collecting and analyzing performance data, these enhanced heat exchangers can adapt to changing conditions, optimize energy consumption, and proactively identify and address potential issues before they arise.

As the world continues to prioritize sustainability and environmental stewardship, the role of air-cooled heat exchangers in reducing water consumption and minimizing the carbon footprint of industrial processes will become increasingly vital. Emerging technologies, such as hybrid air-cooled/water-cooled systems and advanced materials with enhanced thermal properties, hold the potential to further improve the efficiency and environmental impact of these essential thermal management solutions.

By staying at the forefront of air-cooled heat exchanger advancements, https://www.aircooledheatexchangers.net/ is committed to empowering industries with the knowledge and tools to harness the full potential of these remarkable thermal management technologies. Our team of experts is dedicated to providing comprehensive support, from design optimization to maintenance and troubleshooting, ensuring that your air-cooled heat exchangers operate at peak performance and contribute to the success of your business.