In the ever-evolving world of industrial processes, efficient thermal management has emerged as a critical component for optimizing performance, improving energy efficiency, and ensuring equipment reliability. At the forefront of this thermal revolution are air-cooled heat exchangers, versatile and cost-effective solutions that are transforming the way industries manage their heat transfer challenges.

As a seasoned expert in this field, I’m excited to share practical insights and in-depth strategies for leveraging the power of air-cooled heat exchangers to enhance your thermal management capabilities. Whether you’re an engineer, plant manager, or a technical enthusiast, this comprehensive guide will equip you with the knowledge and tools to harness the full potential of these remarkable heat transfer systems.

Understanding the Fundamentals of Air-Cooled Heat Exchangers

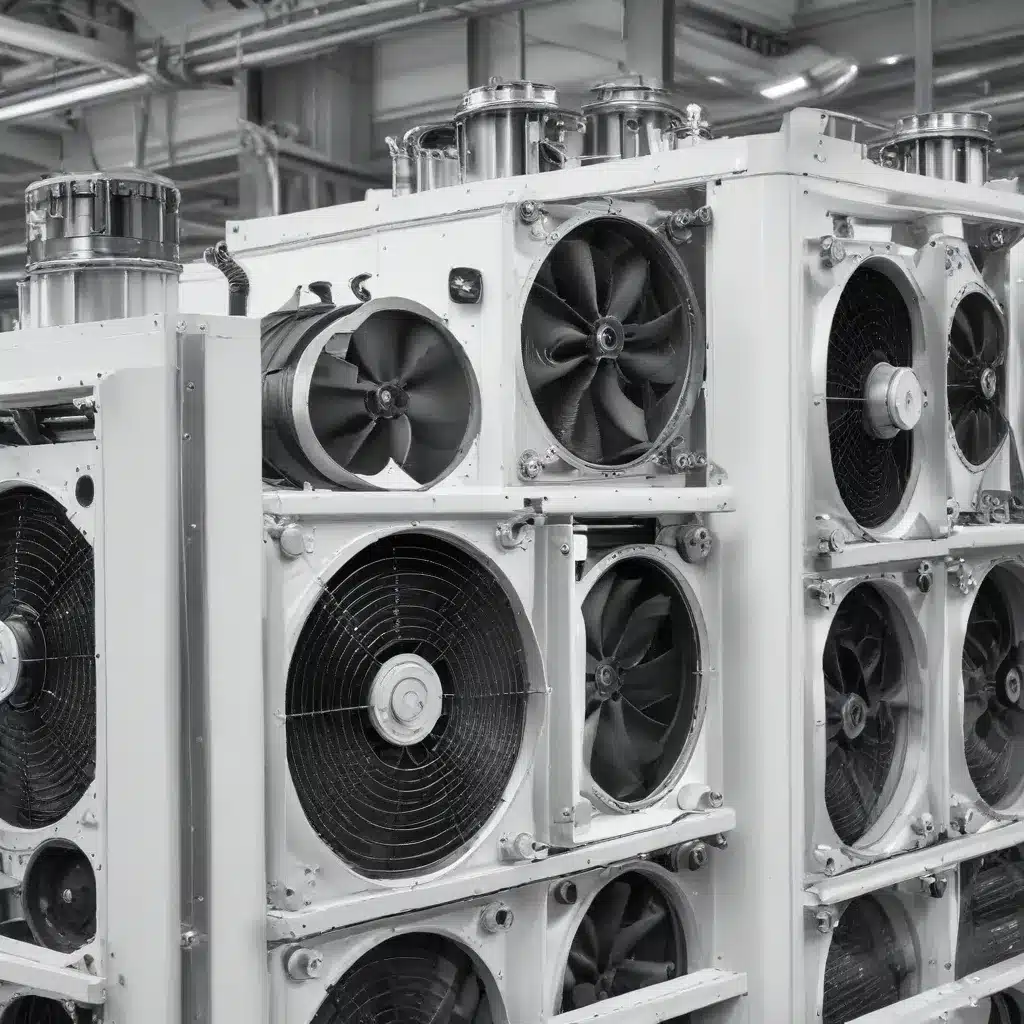

At the heart of an air-cooled heat exchanger lies a simple, yet ingenious principle – the efficient transfer of heat from a fluid or gas to the surrounding air. These heat exchangers rely on the principles of convective heat transfer, wherein the heat is transported from a hotter medium to a cooler one through the motion of the fluid or gas.

The key components of an air-cooled heat exchanger typically include:

- Finned Tubes: These are the primary heat transfer surfaces, designed to maximize the surface area exposed to the cooling air, enhancing the overall heat transfer rate.

- Fans or Blowers: Strategically placed to facilitate the movement of air across the finned tubes, ensuring efficient heat dissipation.

- Casing or Frame: Providing structural support and housing the heat transfer components.

The versatility of air-cooled heat exchangers lies in their ability to handle a wide range of applications, from industrial processes and power generation to HVAC systems and refrigeration units. Their compact design, ease of maintenance, and cost-effectiveness make them an attractive choice for a diverse array of industries.

Optimizing Air-Cooled Heat Exchanger Design and Performance

Designing an air-cooled heat exchanger that delivers optimal performance requires a deep understanding of the underlying heat transfer principles and the specific requirements of the application. Let’s explore some key strategies and techniques for enhancing the design and performance of these critical thermal management systems.

Enhancing Heat Transfer Efficiency

One of the primary factors influencing the performance of an air-cooled heat exchanger is the heat transfer coefficient. Strategies to improve this coefficient include:

-

Optimizing Fin Design: Modifying the fin geometry, such as the fin spacing, height, and thickness, can significantly impact the heat transfer rate. Incorporating advanced fin designs, like louvered or wavy fins, can further enhance the heat transfer efficiency.

-

Improving Air-Side Airflow: Ensuring uniform and turbulent airflow across the heat transfer surfaces is crucial. This can be achieved through the strategic placement of fans or blowers, as well as the design of the air inlet and outlet channels.

-

Incorporating Phase-Change Materials: The integration of phase-change materials (PCMs) into the heat exchanger design can provide additional thermal storage capacity, effectively smoothing out temperature fluctuations and improving overall system efficiency.

-

Employing Hybrid Cooling Strategies: Combining air-cooled heat exchangers with other cooling techniques, such as evaporative cooling or liquid-based systems, can result in enhanced thermal performance and increased versatility.

Optimizing Airflow and Pressure Drop

Minimizing the pressure drop across the heat exchanger is essential for reducing energy consumption and optimizing the overall system efficiency. Techniques to achieve this include:

-

Streamlining Air Inlet and Outlet Designs: Carefully shaping the air inlet and outlet channels can minimize flow disruptions and reduce pressure losses.

-

Incorporating Airflow Optimization Measures: The strategic placement of baffles, flow guides, or air straighteners can help to maintain a uniform and efficient airflow pattern through the heat exchanger.

-

Selecting Appropriate Fan or Blower Technologies: Choosing the right fan or blower system, with considerations for speed, blade design, and energy efficiency, can significantly impact the overall pressure drop and energy consumption.

Addressing Maintenance and Reliability Concerns

Ensuring the long-term reliability and efficiency of air-cooled heat exchangers requires a proactive approach to maintenance and monitoring. Key strategies include:

-

Implementing Preventive Maintenance Protocols: Regular inspections, cleaning, and component replacements can help maintain optimal heat transfer performance and minimize the risk of failures.

-

Monitoring and Diagnostics: Incorporating advanced sensor technologies and data analytics can help identify potential issues, predict maintenance needs, and optimize the operational parameters of the heat exchanger.

-

Selecting Corrosion-Resistant Materials: Choosing materials that are resistant to environmental factors, such as chemicals, humidity, and temperature extremes, can extend the service life of the heat exchanger.

-

Designing for Ease of Maintenance: Incorporating features that facilitate access, disassembly, and cleaning can simplify maintenance tasks and reduce downtime.

By addressing these design, performance, and maintenance considerations, you can unlock the full potential of air-cooled heat exchangers and ensure their seamless integration into your thermal management systems.

Applications and Case Studies of Air-Cooled Heat Exchangers

Air-cooled heat exchangers have found widespread adoption across a diverse range of industries, each with its unique thermal management challenges. Let’s explore some real-world applications and case studies that highlight the versatility and effectiveness of these heat transfer solutions.

Industrial Processes and Manufacturing

In the manufacturing sector, air-cooled heat exchangers play a crucial role in cooling various process fluids, such as lubricants, coolants, and process water. A case study from the Air Cooled Heat Exchangers blog showcases how a leading automotive manufacturer implemented a customized air-cooled heat exchanger system to efficiently cool their cutting fluid, resulting in improved tool life, reduced maintenance, and enhanced product quality.

Power Generation and Energy Systems

In the power generation industry, air-cooled heat exchangers are commonly used for cooling generator components, lubricating oils, and exhaust gases. A research article published in the Energies journal highlights the importance of effective thermal management in electric vehicles, where air-cooled heat exchangers are essential for cooling battery packs, electric motors, and air conditioning systems, ensuring optimal performance and safety.

HVAC and Refrigeration Applications

Air-cooled heat exchangers are integral components in various HVAC and refrigeration systems, serving as condensers or evaporators. The EPA’s guidance on improving indoor air quality emphasizes the role of ventilation and air conditioning in maintaining a comfortable and healthy indoor environment, where air-cooled heat exchangers play a crucial part in the efficient transfer of heat.

Waste Heat Recovery Systems

In industries with significant waste heat, such as metal processing or power generation, air-cooled heat exchangers can be used to recover and repurpose this energy. A scientific article in the Science Direct journal discusses the strategies for improving indoor air quality, including the use of heat recovery ventilators that leverage air-cooled heat exchangers to efficiently transfer heat between the exhaust and incoming air streams.

These diverse applications showcase the versatility and adaptability of air-cooled heat exchangers, highlighting their ability to address a wide range of thermal management challenges across various industries.

Navigating the Future of Air-Cooled Heat Exchanger Technology

As the demand for efficient and sustainable thermal management solutions continues to grow, the future of air-cooled heat exchanger technology is poised for innovative advancements. Let’s explore some emerging trends and potential avenues for future development:

Integrating Renewable Energy Sources

With the increasing focus on renewable energy, air-cooled heat exchangers can play a pivotal role in integrating these technologies into thermal management systems. For example, combining air-cooled heat exchangers with solar thermal or geothermal systems can enable efficient heat recovery and storage, optimizing energy utilization.

Advancements in Materials and Coatings

Continuous research and development in material science and surface engineering are paving the way for air-cooled heat exchangers with enhanced durability, thermal performance, and corrosion resistance. The incorporation of novel materials, such as high-performance alloys or advanced ceramic coatings, can significantly improve the heat transfer capabilities and extend the service life of these critical components.

Intelligent Control and Automation

The integration of advanced control systems, sensor networks, and data analytics can revolutionize the operation and optimization of air-cooled heat exchangers. Predictive maintenance, real-time monitoring, and adaptive control algorithms can help maximize the efficiency, reliability, and responsiveness of these thermal management solutions.

Sustainability and Environmental Considerations

As the global focus on environmental sustainability intensifies, air-cooled heat exchangers are positioned to play a crucial role in reducing energy consumption and carbon footprint. Innovations in energy-efficient fan designs, low-noise operation, and the use of eco-friendly refrigerants can contribute to the development of more sustainable thermal management systems.

By staying at the forefront of these technological advancements, you can position your organization to harness the full potential of air-cooled heat exchangers and stay ahead of the curve in the ever-evolving landscape of thermal management.

Conclusion: Embracing the Future of Air-Cooled Heat Exchanger Technology

In the dynamic world of industrial processes, thermal management has emerged as a critical pillar for optimizing performance, enhancing energy efficiency, and ensuring the reliability of mission-critical systems. Air-cooled heat exchangers have proven to be invaluable assets in this endeavor, offering versatile, cost-effective, and sustainable solutions to a wide range of thermal challenges.

By understanding the fundamental principles, exploring optimization strategies, and staying abreast of the latest advancements in air-cooled heat exchanger technology, you can unlock a world of opportunities for your organization. Whether you’re an engineer, plant manager, or a technical enthusiast, this comprehensive guide has provided you with the knowledge and insights to elevate your thermal management capabilities and embrace the future of this transformative technology.

As you continue your journey in the realm of air-cooled heat exchangers, remember to visit the Air Cooled Heat Exchangers blog for more expert insights, practical tips, and cutting-edge industry trends. Together, let’s push the boundaries of thermal management and unlock new levels of efficiency, sustainability, and innovation.