The Importance of Optimizing Air-Cooled Heat Exchangers

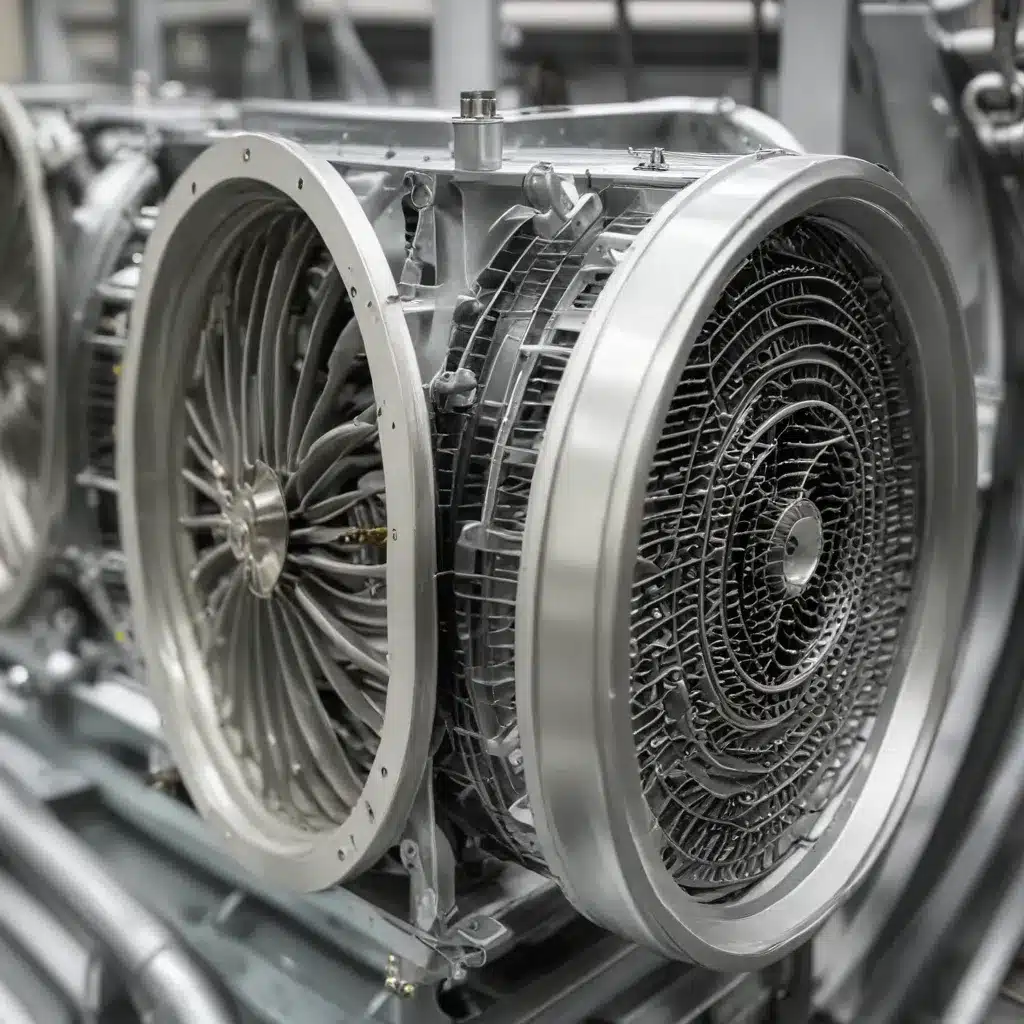

Air-cooled heat exchangers (ACHEs) play a crucial role in various industrial processes, ranging from refining and gas processing to petrochemical operations and carbon capture. These heat transfer workhorses cool process fluids, condense vapors, and maintain optimal temperatures – all while striving to maximize energy efficiency. Optimizing the design, engineering, and maintenance of ACHEs can have a significant impact on a facility’s overall operational effectiveness and cost-efficiency.

Enhancing the energy efficiency of air-cooled heat exchangers involves a multifaceted approach, leveraging advanced techniques in fin and tube design, air flow optimization, and smart monitoring. By delving into these cutting-edge strategies, industrial operators can unlock substantial improvements in thermal performance, reduce energy consumption, and extend the lifespan of their ACHE assets.

Fin Design Innovations for Enhanced Heat Transfer

The choice of fin type is a crucial factor in optimizing the performance and durability of air-cooled heat exchangers. Fin design directly impacts heat transfer efficiency, corrosion resistance, and suitability for different operating environments. Let’s explore the key differences between the most common fin types and their applications:

L-Fins

L-fins are formed by wrapping a strip of metal (typically aluminum) around the base tube, creating an ‘L’ shape. These fins are commonly used in moderate environments due to their cost-effectiveness, but they can be susceptible to mechanical damage and corrosion under harsher conditions. L-fins also have a temperature limitation of 275°F (135°C), as they begin to expand and detach from the tube above this threshold, significantly impairing heat transfer.

Embedded Fins

In embedded fin designs, the fin material is wound into a helical groove cut into the outer surface of the tube. This method provides excellent heat transfer efficiency and a strong mechanical bond between the fin and tube, making it suitable for process streams with temperatures exceeding 275°F (135°C). Embedded fins are widely used in petrochemical and industrial processing applications where higher operating temperatures are encountered.

Extruded Fins

Extruded fins are formed by forcing both the tube and fin material (typically aluminum) through a die in a single step, creating a robust, integral bond. This design produces fins that are highly resistant to atmospheric corrosion and mechanical damage, making them ideal for harsh operating environments such as offshore platforms, chemical plants, and areas with high levels of airborne contaminants.

The selection of the appropriate fin type depends on the specific environmental conditions, required heat transfer efficiency, cost considerations, and maintenance practices of the industrial facility. By carefully evaluating these factors, engineers can optimize the fin design to enhance the energy efficiency and longevity of air-cooled heat exchangers.

Advancing Tube Geometries for Improved Heat Transfer

In addition to fin design, the geometry and surface enhancements of the heat exchanger tubes can significantly impact thermal performance. Innovative tube configurations and internal features can increase turbulence, optimize heat transfer coefficients, and mitigate fouling – all of which contribute to enhanced energy efficiency.

Corrugated and Dimpled Tubes

Tubes with corrugated or dimpled surfaces create increased turbulence, which leads to higher heat transfer coefficients compared to smooth tubes. This enhanced heat transfer can be particularly beneficial in scenarios with laminar flow regimes, where passive tube inserts provide a significant performance boost.

Tube Inserts and Enhancements

The integration of tube inserts, such as twisted tapes or wire mesh (e.g., hiTRAN® Calgavin Matrix), can also improve heat transfer efficiency. These passive inserts create additional turbulence and disrupt the boundary layer, resulting in higher heat transfer rates, especially in laminar flow conditions.

Optimized Tube Layouts and Baffles

The arrangement and configuration of the tube bundle, including the use of advanced baffle designs, can have a profound impact on the air flow distribution and overall heat transfer performance. Computational fluid dynamics (CFD) analysis enables engineers to fine-tune baffle spacing, cut percentage, and orientation to achieve an optimal balance of heat transfer and pumping power.

By incorporating these innovative tube geometries and layout optimizations, industrial operators can maximize the thermal efficiency of their air-cooled heat exchangers, reducing energy consumption and operating costs.

Material Selection and Coatings for Improved Durability

As industrial processes push the limits of temperature, pressure, and chemical corrosion, the selection of appropriate materials for air-cooled heat exchangers becomes increasingly critical. High-performance alloys and protective coatings can extend the lifespan of ACHE components, minimizing the need for costly maintenance and replacements.

Advanced Alloy Materials

Stainless steels (304, 316, etc.) and Duplex alloys (S31803, S32205) are commonly specified for their corrosion resistance, but in extreme operating conditions, even higher-performance nickel alloys may be necessary. Materials like Inconel® (600, 625), Incoloy® (800, 825), Hastelloy® (C-22, C-276, C-2000), and VDM® Alloy-59 offer enhanced resistance to corrosion, elevated temperatures, and aggressive chemical environments.

Protective Coatings and Cathodic Protection

Thin-film coatings can provide a powerful barrier against corrosion and fouling, further enhancing the durability and efficiency of air-cooled heat exchangers. Coatings like Curran International’s CurraMix have demonstrated oleophobic and hydrophobic anti-fouling properties, extending the time between cleanings.

For systems prone to galvanic corrosion, a well-designed cathodic protection system can dramatically extend equipment life and reduce maintenance costs. By combining advanced alloys and protective coatings, industrial facilities can ensure their air-cooled heat exchangers operate reliably and efficiently for an extended service life.

Harnessing Digital Technologies for Optimized Performance

The advent of low-cost Internet of Things (IoT) sensors, artificial intelligence (AI), and cloud computing has unlocked new frontiers in air-cooled heat exchanger performance optimization. By leveraging these digital technologies, industrial operators can achieve enhanced monitoring, predictive maintenance, and operational optimization.

Real-Time Performance Monitoring

Strategically placed IoT sensors can provide real-time monitoring of key parameters, such as temperatures, pressures, and flow rates, within the air-cooled heat exchanger system. This wealth of data enables early detection of fouling, equipment degradation, or other performance issues, allowing for proactive maintenance and optimization.

Predictive Maintenance and Digital Twins

Machine learning algorithms can analyze the collected sensor data to predict future performance trends and identify optimal maintenance schedules. Some companies are even developing “digital twin” models of their air-cooled heat exchangers, allowing for virtual testing of different operating scenarios and maintenance strategies before implementation in the physical system.

Intelligent Control and Optimization

By integrating IoT sensors, AI, and cloud computing, industrial facilities can achieve intelligent control and optimization of their air-cooled heat exchanger systems. Automated adjustments to fan speeds, air flow, and other parameters can be made in real-time to maintain optimal thermal efficiency and energy consumption, while accounting for changing process demands and environmental conditions.

Embracing these digital technologies enables industrial operators to maximize the energy efficiency and performance of their air-cooled heat exchangers, ultimately driving down operating costs and enhancing overall process reliability.

Comprehensive Maintenance and Troubleshooting Strategies

Maintaining the optimal performance and energy efficiency of air-cooled heat exchangers requires a comprehensive approach to maintenance and troubleshooting. Regular inspections, proactive cleaning, and timely repairs are essential to address common issues and ensure long-term reliability.

Mechanical Component Maintenance

Routine maintenance of mechanical components, such as fans, bearings, belt drives, and motors, is crucial for maintaining the efficiency and longevity of air-cooled heat exchangers. Regular lubrication, inspections, and timely repairs of these components can prevent unexpected downtime and optimize energy consumption.

Fouling Management

Fouling can occur both inside and outside the heat exchanger tubes, impacting thermal performance and efficiency. Effective fouling management strategies, including regular cleaning, the use of anti-fouling coatings, and ensuring proper fluid velocities, are essential to maintain optimal heat transfer and reduce energy consumption.

Leak Identification and Repair

Identifying and repairing leaks in air-cooled heat exchangers, particularly at the header plugs, is vital for maintaining system integrity and preventing further damage. The repair process often involves cleaning the plug and header threads, replacing seals and/or plugs, and ensuring a tight, leak-free seal through proper torqueing.

Noise Reduction Techniques

In air-cooled heat exchangers, selecting the right fan, motor, and drive system is crucial for effective noise reduction. Opting for larger diameter fans that operate at lower speeds, incorporating fan rings, and using high-efficiency motors with variable frequency drives (VFDs) can significantly decrease noise output without compromising performance.

By implementing comprehensive maintenance and troubleshooting strategies, industrial operators can ensure their air-cooled heat exchangers continue to operate at peak efficiency, minimizing energy consumption and extending the lifespan of these critical assets.

Conclusion: Optimizing for a Sustainable Future

Air-cooled heat exchangers play a pivotal role in diverse industrial processes, from petrochemical and gas processing to carbon capture and beyond. By embracing advanced fin and tube optimization techniques, innovative material selections, and digital technologies, industrial operators can unlock substantial improvements in the energy efficiency and reliability of their ACHE systems.

Through thoughtful design, engineering, and maintenance, air-cooled heat exchangers can become beacons of sustainability, reducing energy consumption, minimizing environmental impact, and driving down operating costs. As industries strive to meet ever-evolving efficiency and environmental standards, the strategic optimization of air-cooled heat exchangers will remain a crucial focus area for forward-thinking industrial leaders.

To learn more about how https://www.aircooledheatexchangers.net/ can help you enhance the performance and energy efficiency of your air-cooled heat exchangers, please don’t hesitate to reach out to our team of experts.