The Power of Nature-Inspired Designs

As the world grapples with the pressing need to improve energy efficiency, the field of air-cooled heat exchangers has become a critical frontier for innovation. These ubiquitous devices play a vital role in countless industrial processes, from power generation to HVAC systems, making the optimization of their heat transfer capabilities a paramount concern.

Fortunately, nature provides a wealth of inspiration for engineers seeking to enhance the performance of air-cooled heat exchangers. By studying the intricate surface structures and fluid dynamics observed in biological systems, researchers have uncovered a treasure trove of biomimetic design principles that can dramatically improve heat transfer and reduce flow resistance.

In this comprehensive article, we will delve into the latest advancements in biomimetic surface structures and explore how they can be leveraged to elevate the efficiency of air-cooled heat exchangers. From fractal-inspired branching channels to self-cleaning superhydrophobic surfaces, the natural world holds the keys to unlocking a new era of thermal management.

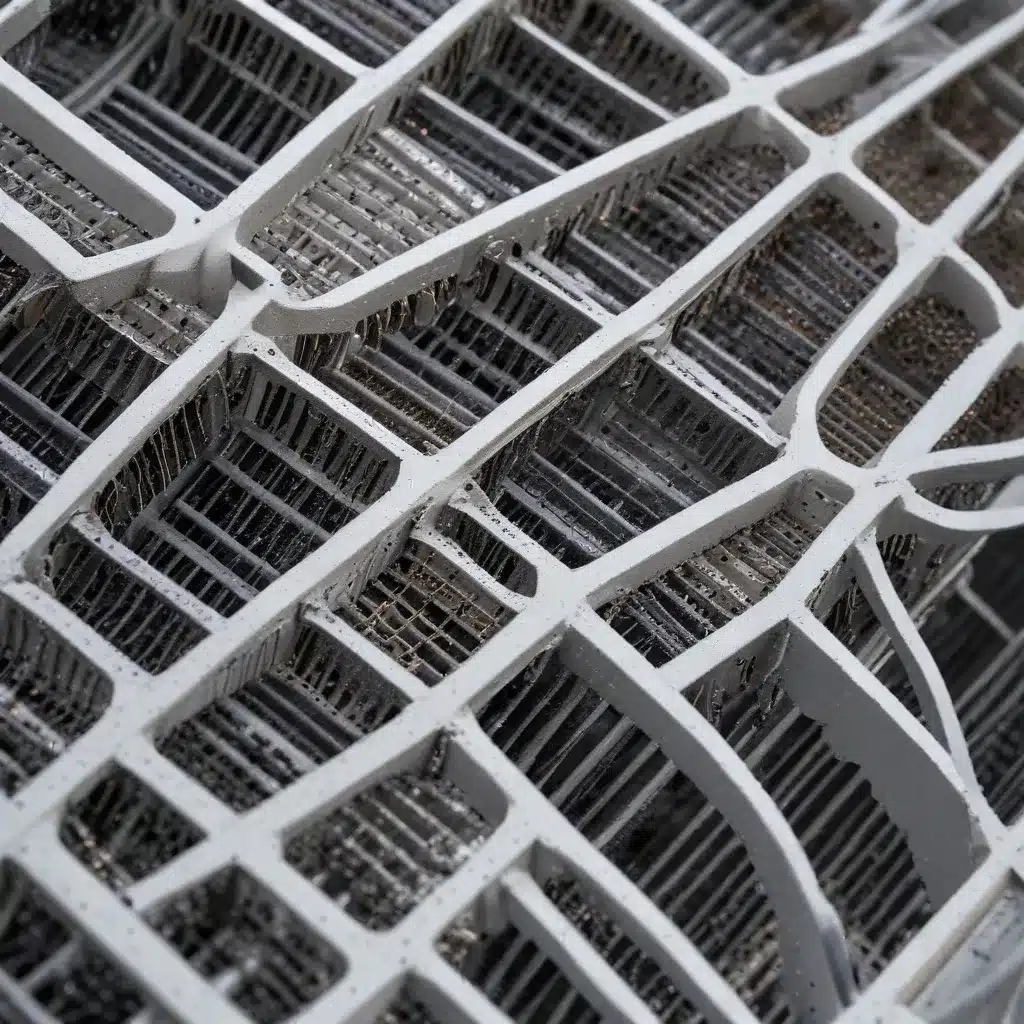

Fractal-Inspired Branching Channels

One of the most captivating biomimetic structures for heat exchanger design is the fractal-tree-like configuration, inspired by the intricate branching patterns found in nature. From the delicate veins of leaves to the complex networks of the human circulatory system, fractal geometries have long been recognized for their ability to optimize the distribution of flows and maximize heat transfer.

By replicating these fractal-inspired branching channels in the design of air-cooled heat exchangers, researchers have achieved remarkable improvements in thermal performance. The unique characteristics of these fractal-tree-like structures, such as the number and angle of branches, the aspect ratio of the channels, and the layered configuration, have been shown to have a profound impact on heat transfer coefficients and flow resistance.

For example, studies have demonstrated that the transition from single-layer to multi-layer fractal-tree-like microchannels can significantly reduce the overall thermal resistance, while the incorporation of micro-ribs within the fractal-tree-like geometry can disrupt the boundary layer and enhance the Nusselt number. Furthermore, the use of fractal-tree-like channels in spiral-tube heat exchangers has been shown to increase the total heat flux by up to 23% compared to conventional designs.

Biomimetic Surfaces for Improved Condensation

Another area where nature-inspired designs have had a profound impact on air-cooled heat exchanger performance is in the realm of condensation heat transfer. The ability of certain plant and animal surfaces to effectively manage the formation and removal of condensate droplets has captivated the attention of researchers seeking to optimize the heat transfer capabilities of these devices.

Take, for example, the unique surface structures found on the leaves of the Lychnis sibirica plant or the spiny cactus. These surfaces are adorned with conical column structures that leverage the principles of wettability and Laplace pressure gradients to drive the spontaneous movement of condensate droplets, ultimately enhancing the heat transfer process.

Similarly, the self-cleaning and self-jumping behavior observed on the wings of cicadas has inspired the development of biomimetic surfaces with coordinated conical column structures and hydrophobic wax layers. By carefully engineering the height, tip size, and spacing of these nano-scale features, researchers have reported up to a 320% increase in the condensation heat transfer coefficient compared to smooth hydrophobic surfaces.

Hybrid Wetting Surfaces: Balancing Hydrophilicity and Hydrophobicity

Building upon the insights gained from nature’s moisture-management strategies, researchers have explored the concept of hybrid wetting surfaces, where hydrophilic and hydrophobic regions are deliberately combined to optimize the condensation process.

Inspired by the Namib desert beetle’s back, which features a unique blend of hydrophilic protrusions and hydrophobic grooves, these hybrid wetting surfaces have demonstrated remarkable heat transfer improvements. By leveraging the ability of the hydrophilic regions to gather suspended droplets and the hydrophobic areas to facilitate droplet flow and removal, the hybrid wetting surfaces have been shown to effectively prevent film condensation and promote the more efficient dropwise condensation regime.

The design parameters of these hybrid wetting surfaces, such as the pattern shape, inclined angle, spatial layout, and fractional area of the hydrophilic and hydrophobic regions, have all been found to play a crucial role in their heat transfer performance. Researchers have explored a wide range of configurations, from dot patterns and parallel stripes to interdigitated and staggered line designs, each offering unique advantages in terms of condensation efficiency and flow dynamics.

Biomimetic Surfaces for Flow Resistance Reduction

In addition to enhancing heat transfer, biomimetic surface structures have also proven invaluable in the pursuit of reducing flow resistance within air-cooled heat exchangers. By taking inspiration from the adaptations of various organisms, engineers have developed a suite of surface textures and geometries that can effectively mitigate the viscous and form drag that plague these systems.

The most well-known example is the biomimetic shark skin, which has inspired the design of grooved surfaces that can alter the flow patterns within the turbulent boundary layer, ultimately reducing the viscous resistance experienced by the fluid. Researchers have explored a variety of groove geometries, including triangular, trapezoidal, semicircular, and saw-tooth profiles, each with their own unique capabilities in terms of drag reduction.

Beyond shark skin, other natural surfaces have also provided valuable insights. The multilevel scale structures of grass carp, for instance, have been shown to reduce the friction coefficient in microchannels by up to 5%, while the concave-convex geometries observed in the armor of dung beetles, the backs of cybister bengalensis, and the fins of humpback whales have been leveraged to generate vortex cushion effects and low-velocity flow zones that diminish the overall flow resistance.

Superhydrophobic Surfaces: Nature’s Drag-Reducing Wonders

Perhaps one of the most fascinating examples of biomimetic surfaces for flow resistance reduction is the superhydrophobic lotus leaf. Inspired by the intricate micro-nano composite structure of this natural masterpiece, researchers have developed a wide range of synthetic superhydrophobic surfaces that can harness the power of the gas-liquid interface to significantly reduce viscous drag.

The hierarchical features found on the lotus leaf, consisting of papillary epidermal cells and waxy crystals, allow it to absorb air and replace part of the solid-liquid contact with a gas-liquid interface. As a result, fluid flowing over the lotus leaf experiences a slip motion, which reduces the velocity gradient and shear stress near the boundary, thus delaying the transition to turbulent flow and decreasing the overall viscous resistance.

By replicating these superhydrophobic micro-nano structures, researchers have reported impressive drag reduction rates of up to 30% on various materials, including aluminum and polymer-based surfaces. This biomimetic approach to flow resistance management holds immense promise for enhancing the efficiency of air-cooled heat exchangers, particularly in applications where minimizing pump power consumption is a critical design consideration.

Advancing Biomimetic Manufacturing

The successful implementation of biomimetic surface structures in air-cooled heat exchangers relies heavily on the development of advanced micro- and nano-scale manufacturing techniques. Fortunately, the scientific community has made significant strides in this area, unveiling a range of processing methods that can faithfully replicate the intricate features found in nature.

Photolithography, for instance, has proven to be a highly versatile tool for fabricating micro-nano structures, allowing for the precise control of feature size, shape, and arrangement. This technique has been leveraged to create a variety of bioinspired surface textures, from the inclined arc pitted grooves that mimic the curved outlines of Nepenthes alata to the hydrophilic-hydrophobic composite patterns inspired by the Namib desert beetle.

Complementing photolithography, nanoimprinting has emerged as a powerful technique for directly transferring nano-scale features from a master template to a target material, enabling the large-scale production of biomimetic structures with resolutions down to 5 nanometers.

Meanwhile, the advent of femtosecond laser processing has opened up new frontiers in the realm of biomimetic surface fabrication. This non-contact, environmentally friendly method allows for the creation of complex hierarchical structures, such as the superhydrophilic micro-mountain arrays and superhydrophobic bumps with nanoscale protrusions that emulate the surface features of fish scales and lotus leaves.

Finally, the rise of additive manufacturing, or 3D printing, has provided engineers with a powerful tool for rapidly prototyping and fabricating biomimetic structures. From the synthetic shark skin membranes to the superhydrophobic eggbeater-shaped hairs inspired by the Salvinia molesta leaf, 3D printing has demonstrated its versatility in bringing nature-inspired designs to life.

The Future of Biomimetic Air-Cooled Heat Exchangers

As the world continues to grapple with the pressing need for improved energy efficiency, the potential of biomimetic surface structures in air-cooled heat exchangers has never been more promising. By taking inspiration from the intricate adaptations found in nature, engineers and researchers have uncovered a wealth of design principles that can dramatically enhance heat transfer and reduce flow resistance, paving the way for a new generation of high-performance thermal management systems.

Looking ahead, the future of biomimetic air-cooled heat exchangers holds tremendous promise. As we continue to deepen our understanding of the synergistic effects between various biological surface features, we can expect to see the development of increasingly sophisticated composite structures that seamlessly integrate the best of what nature has to offer.

Moreover, the ongoing advancements in micro- and nano-scale manufacturing techniques will enable the faithful replication of these nature-inspired designs, allowing for the mass-production of high-efficiency heat exchangers that can be tailored to a wide range of industrial applications.

By embracing the power of biomimicry, the air-cooled heat exchanger industry is poised to embark on a new era of innovation, where the solutions to our most pressing thermal management challenges can be found in the remarkable adaptations of the natural world. As we continue to push the boundaries of what is possible, the future of air-cooled heat exchanger technology has never been brighter.