Mastering the Art of Efficient Thermal Management

In the ever-evolving landscape of power generation, industrial processes, and environmental stewardship, the humble air-cooled heat exchanger has emerged as a silent hero, tackling thermal challenges head-on. As the world becomes increasingly conscious of its environmental impact, the role of these versatile heat transfer devices has taken on a new level of importance, serving as a vital link between energy efficiency and sustainable operations.

Unraveling the Complexities of Air-Cooled Heat Exchangers

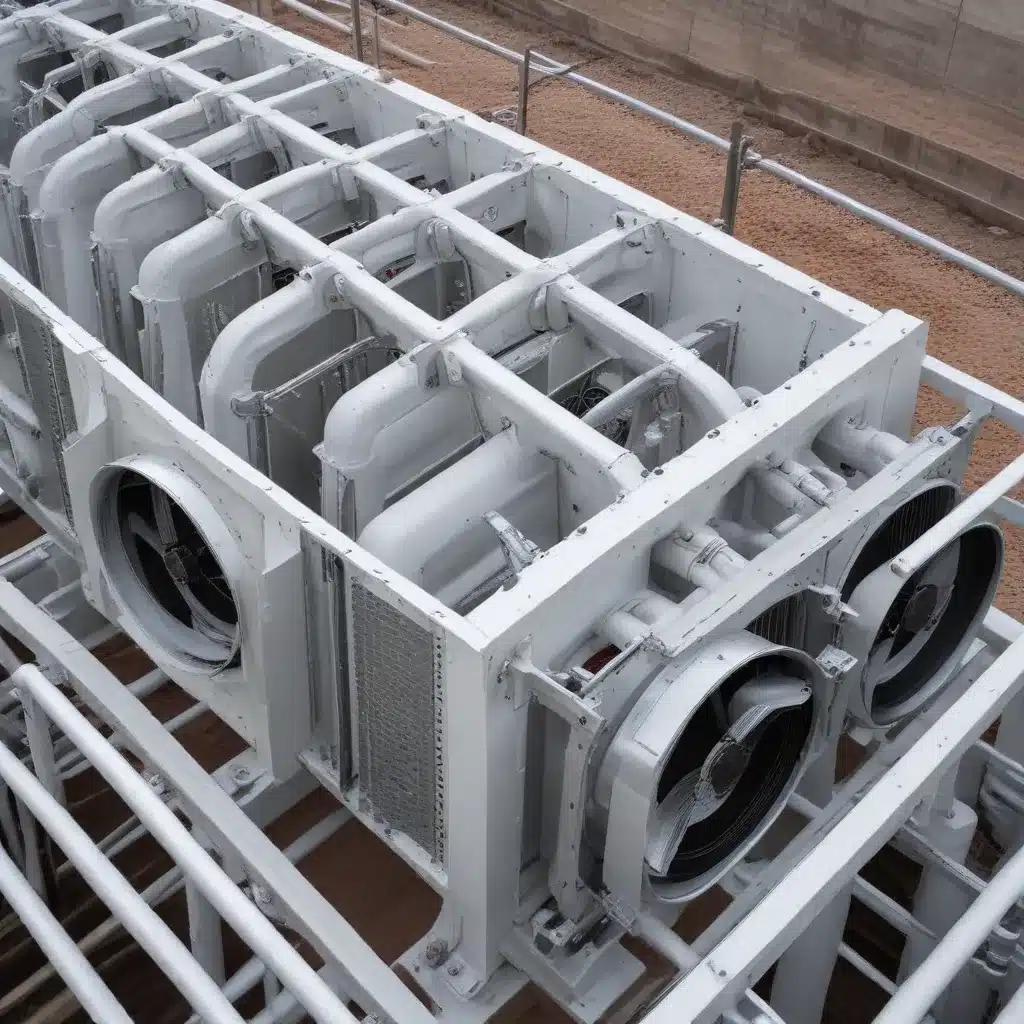

Air-cooled heat exchangers are engineered marvels that leverage the principles of convection to dissipate excess heat. Unlike their water-cooled counterparts, these systems rely on the circulation of ambient air to absorb and disperse thermal energy, eliminating the need for water-intensive cooling methods. This not only reduces the strain on freshwater resources but also opens up new possibilities for facility siting and deployment, especially in regions with limited water availability.

At the heart of an air-cooled heat exchanger lies a network of finned tubes or plates, through which a process fluid, such as steam, oil, or refrigerant, flows. As this fluid travels through the heat exchanger, the ambient air is drawn across the fins, facilitating the transfer of heat from the process fluid to the surrounding atmosphere. This elegant design allows for the continuous removal of unwanted heat, enabling efficient and reliable operation in a wide range of industrial and power generation applications.

Navigating the Evolving Landscape of Environmental Responsibility

The growing emphasis on environmental stewardship has placed air-cooled heat exchangers firmly in the spotlight. As regulatory bodies around the world impose stricter guidelines on water usage and emissions, the inherent advantages of these air-based systems have become increasingly attractive. By minimizing the reliance on water resources, air-cooled heat exchangers help organizations reduce their environmental footprint and comply with evolving sustainability standards.

Moreover, the energy-efficient nature of air-cooled heat exchangers contributes to the overall optimization of industrial and power generation processes. By effectively managing thermal loads, these systems help to enhance the overall efficiency of a facility, reducing energy consumption and the associated carbon emissions. This alignment with the global drive towards sustainability has made air-cooled heat exchangers an indispensable component in the quest for a greener future.

Designing for Optimal Performance and Reliability

Designing high-performance, reliable air-cooled heat exchangers requires a deep understanding of thermal engineering principles, fluid dynamics, and material science. Seasoned experts in this field meticulously consider a multitude of factors, from the selection of materials and fin geometries to the design of the airflow paths and the integration of advanced monitoring and control systems.

The choice of materials, for instance, plays a crucial role in the overall performance and longevity of an air-cooled heat exchanger. Corrosion-resistant alloys, such as stainless steel or aluminum, are often employed to withstand the harsh operating environments, ensuring long-term durability and minimizing the need for costly maintenance or replacement.

Fin design is another critical aspect, as the geometry and spacing of the fins directly impact the heat transfer efficiency and the pressure drop experienced by the airflow. Computational fluid dynamics (CFD) simulations and advanced modeling techniques are utilized to optimize fin configurations, enabling engineers to precisely predict and enhance the thermal performance of their designs.

Alongside these technical considerations, the integration of monitoring and control systems has become increasingly important. Advanced sensors and control algorithms allow for real-time monitoring of key parameters, such as airflow, pressure, and temperature, enabling proactive maintenance and optimization of the heat exchanger’s operation. This level of intelligence not only enhances reliability but also helps to minimize energy consumption and maximize the overall efficiency of the system.

Maintaining Peak Performance through Comprehensive Care

Ensuring the long-term reliability and efficiency of air-cooled heat exchangers requires a comprehensive maintenance regime. Regular inspections, cleaning, and preventive measures are essential to keep these systems operating at their peak performance.

One of the primary challenges faced by air-cooled heat exchangers is the accumulation of airborne contaminants, such as dust, dirt, or organic matter, on the fin surfaces. This buildup can significantly impede the airflow and diminish the heat transfer capabilities of the system, leading to decreased efficiency and potential equipment failure. Diligent cleaning protocols, utilizing techniques like high-pressure water washing or chemical cleaning, are crucial to maintaining the heat exchanger’s thermal effectiveness.

Beyond cleaning, periodic inspections of the mechanical components, such as fans, bearings, and drive systems, help to identify and address any potential issues before they escalate. Proactive maintenance, including the replacement of worn parts and the proper lubrication of moving components, ensures the long-term reliability of the air-cooled heat exchanger.

Integrating advanced monitoring systems further enhances the maintenance process, providing real-time data on the system’s performance and allowing for targeted, condition-based interventions. By anticipating and addressing potential problems before they arise, organizations can minimize unplanned downtime, extend the lifespan of their air-cooled heat exchangers, and optimize their overall operational efficiency.

Adapting to Diverse Industrial Applications

The versatility of air-cooled heat exchangers has made them an indispensable asset across a wide range of industrial sectors, from power generation and petrochemical processing to data centers and HVAC systems.

In the power generation industry, air-cooled heat exchangers play a crucial role in the cooling of steam turbines and other critical components, ensuring the reliable and efficient operation of both conventional and renewable energy plants. These systems are particularly valuable in regions with limited water resources, where their water-free cooling capabilities provide a sustainable alternative to traditional water-cooled designs.

Similarly, in the petrochemical and refining industries, air-cooled heat exchangers are utilized extensively to cool process streams, catalysts, and other heat-sensitive components. Their ability to operate in harsh environments and withstand the rigors of industrial processes make them an essential part of these complex facilities.

The rise of data centers and the accompanying surge in computing power has also driven the increased adoption of air-cooled heat exchangers. These systems are instrumental in maintaining the optimal operating temperatures of server racks and other sensitive electronic equipment, contributing to the overall efficiency and reliability of data infrastructure.

In the realm of HVAC (Heating, Ventilation, and Air Conditioning) systems, air-cooled heat exchangers find application in chiller units, rooftop units, and other climate control solutions. By effectively dissipating heat, these exchangers help to maintain comfortable indoor environments while minimizing the environmental impact of traditional cooling systems.

Navigating the Future of Thermal Management

As the world continues to grapple with the challenges of environmental sustainability, the role of air-cooled heat exchangers is poised to become even more crucial. These innovative thermal management solutions offer a pathway towards a greener future, empowering industries to enhance their energy efficiency, reduce water consumption, and minimize their carbon footprint.

The future of air-cooled heat exchangers will likely see the integration of advanced materials, optimized fin geometries, and intelligent control systems. Cutting-edge technologies, such as additive manufacturing and predictive maintenance algorithms, will further enhance the performance, reliability, and longevity of these critical components.

Moreover, the ongoing research and development in areas like hybrid cooling systems, which combine air-cooled and water-cooled approaches, promise to unlock new levels of thermal management efficiency. These hybrid solutions leverage the strengths of both cooling methods, offering enhanced flexibility and the ability to adapt to diverse operating conditions and environmental constraints.

As we navigate the complex landscape of environmental responsibility, air-cooled heat exchangers stand as a testament to the power of innovative engineering. By conquering thermal challenges and driving sustainable progress, these unsung heroes are poised to play a pivotal role in shaping a more energy-efficient and resource-conscious future for all.

Unlocking the Potential of Air-Cooled Heat Exchangers

The journey towards environmental responsibility is not without its challenges, but air-cooled heat exchangers have emerged as a crucial ally in this pursuit. By leveraging the power of convection and optimizing thermal management, these versatile systems are redefining the way industries approach energy efficiency and sustainability.

Whether you’re a power plant operator, a petrochemical engineer, or a data center manager, the insights and best practices shared in this article can help you unlock the full potential of air-cooled heat exchangers in your operations. By understanding the design considerations, maintenance strategies, and emerging industry trends, you can make informed decisions that will drive your organization towards a more sustainable future.

Explore the Air Cooled Heat Exchangers website to delve deeper into the world of these remarkable thermal management solutions and discover how they can help you conquer your own thermal challenges. Together, we can pave the way for a greener, more efficient tomorrow.