As a seasoned expert in the world of air-cooled heat exchangers, I’m thrilled to share with you some cutting-edge techniques that can significantly improve heat transfer rates in these vital industrial systems. Whether you’re working in the upstream, midstream, downstream, refinery, petrochemical, or power generation sectors, understanding how to optimize the performance of your air-cooled heat exchangers can make a world of difference in terms of efficiency, productivity, and cost-savings.

Optimizing Fin Design for Enhanced Heat Transfer

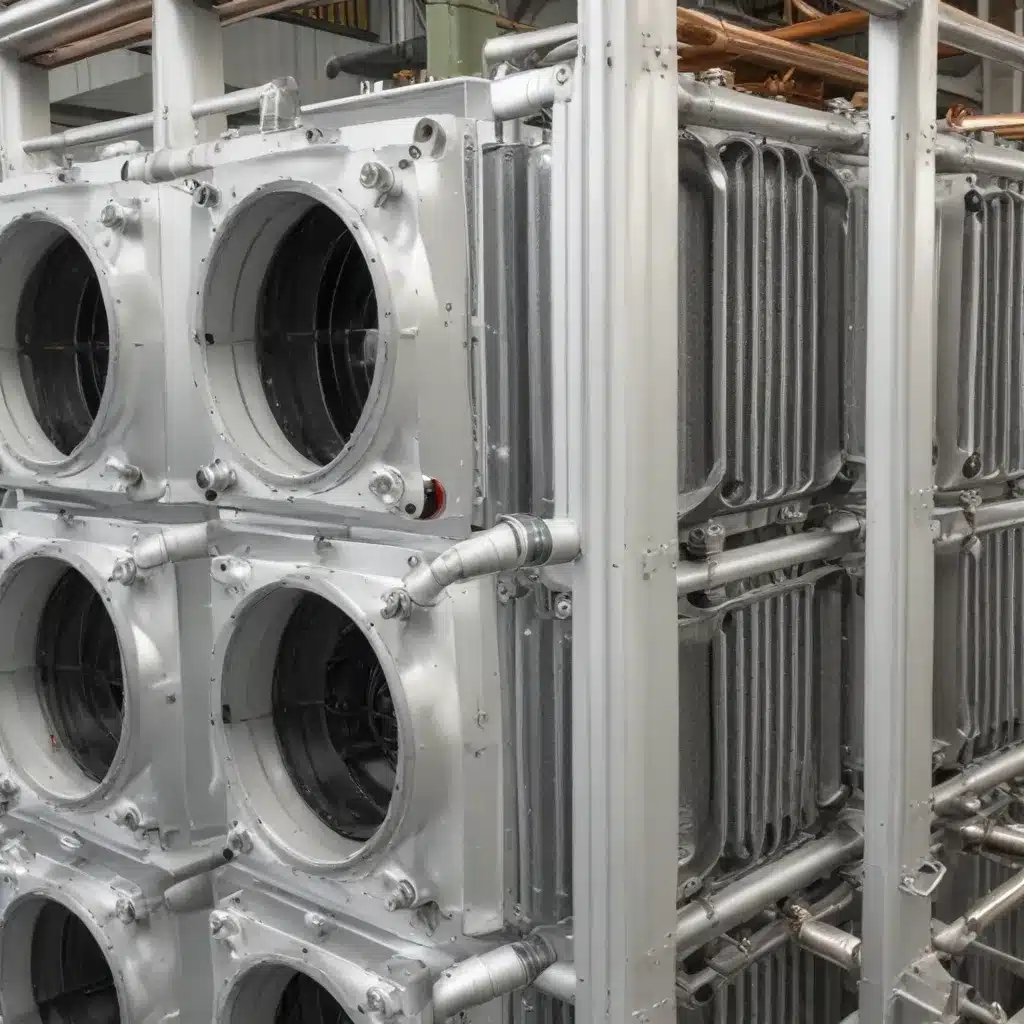

One of the most impactful innovations in air-cooled heat exchanger technology has been the development of advanced fin designs. The humble fin, responsible for dramatically increasing the surface area available for heat transfer, has undergone a remarkable evolution in recent years.

By carefully engineering the shape, density, and material composition of fins, manufacturers like Hudson Products have been able to dramatically improve heat transfer rates. For example, their patented Tuf-Lite® fins not only offer superior structural integrity but also exhibit enhanced heat transfer capabilities through innovative geometries and material choices.

Fin Optimization Strategies:

– Fin Density: Increasing the number of fins per unit length can boost surface area and heat transfer, but careful consideration must be given to airflow resistance and pressure drop.

– Fin Geometry: Experimenting with different fin shapes, such as wavy, louvered, or serrated designs, can promote turbulent airflow and improve convective heat transfer.

– Fin Materials: Employing high-thermal-conductivity materials, like aluminum alloys, can enhance the rate of heat transfer from the process fluid to the fin surface.

By working closely with leading air-cooled heat exchanger providers, such as Chart Industries, you can leverage their expertise in fin design optimization to achieve significant improvements in your heat transfer performance.

Optimizing Airflow and Fans for Maximum Efficiency

The airside of an air-cooled heat exchanger is just as critical as the process fluid side when it comes to maximizing heat transfer rates. Innovative fan technologies and strategic airflow management can have a profound impact on overall system efficiency.

Fan Optimization Strategies:

– Fan Design: Advancements in axial fan technology, like those offered by Chart’s Tuf-Lite® brand, have resulted in fans with higher aerodynamic efficiency, reduced noise, and extended service life.

– Fan Placement: Carefully positioning fans to create an optimal airflow pattern across the heat exchanger can dramatically improve heat transfer performance.

– Variable-Speed Fans: Incorporating variable-speed fan drives allows for dynamic airflow adjustment, enabling the system to adapt to changing heat load conditions and optimize energy consumption.

By working closely with experts in air-cooled heat exchanger design, such as the team at Chart’s Air-X-Changers brand, you can unlock the full potential of your airside system and drive substantial improvements in heat transfer efficiency.

Leveraging Advanced Materials and Coatings

The selection of materials and coatings used in air-cooled heat exchanger construction can have a significant impact on heat transfer performance, durability, and maintenance requirements. Innovative material solutions and protective coatings can provide game-changing advantages.

Material and Coating Optimization Strategies:

– Tube and Fin Materials: Exploring alternative materials, such as high-performance aluminum alloys or copper-based alloys, can enhance thermal conductivity and resistance to corrosion.

– Protective Coatings: Applying specialized coatings to heat exchanger components can improve resistance to fouling, corrosion, and environmental degradation, leading to extended service life and reduced maintenance.

– Additive Manufacturing: Leveraging the capabilities of additive manufacturing (3D printing) can enable the creation of complex, customized fin and tube geometries for optimal heat transfer performance.

By partnering with industry-leading manufacturers like Chart Industries, you can gain access to the latest advancements in air-cooled heat exchanger materials and coatings, ensuring your systems operate at peak efficiency for years to come.

Embracing Digitalization and Predictive Maintenance

The integration of digital technologies and predictive maintenance strategies is transforming the way air-cooled heat exchangers are designed, operated, and maintained. By harnessing the power of data analytics, Internet of Things (IoT) sensors, and advanced monitoring systems, you can optimize the performance and lifespan of your critical assets.

Digital Optimization Strategies:

– Condition Monitoring: Deploying IoT sensors to continuously monitor key parameters, such as vibration, temperature, and pressure, can provide early warning signs of potential issues, enabling proactive maintenance.

– Predictive Analytics: Leveraging sophisticated data analysis and machine learning algorithms can help predict equipment failures, allowing for targeted interventions and avoiding unplanned downtime.

– Digital Twins: Creating virtual replicas of your air-cooled heat exchangers can enable advanced simulations, optimization, and remote monitoring, leading to improved performance and efficiency.

By embracing these digital transformation initiatives, in partnership with experienced providers like Chart’s Hudson Service team, you can unlock new levels of operational excellence and ensure your air-cooled heat exchangers continue to deliver optimal performance for years to come.

Conclusion

As an industry veteran, I’ve witnessed the remarkable evolution of air-cooled heat exchanger technology. From innovative fin designs and fan optimization to advanced materials and digital solutions, the opportunities to improve heat transfer rates and overall system efficiency are truly endless.

By collaborating with leading manufacturers and service providers, such as the brands under the Chart Industries umbrella, you can access the latest advancements, expert insights, and comprehensive aftermarket support to ensure your air-cooled heat exchangers operate at peak performance.

Unlock the full potential of your air-cooled heat exchanger systems and drive measurable improvements in productivity, energy savings, and environmental sustainability. Embrace these innovative techniques and propel your operations to new heights of excellence.