Understanding the Fundamentals of Air-Cooled Heat Exchangers

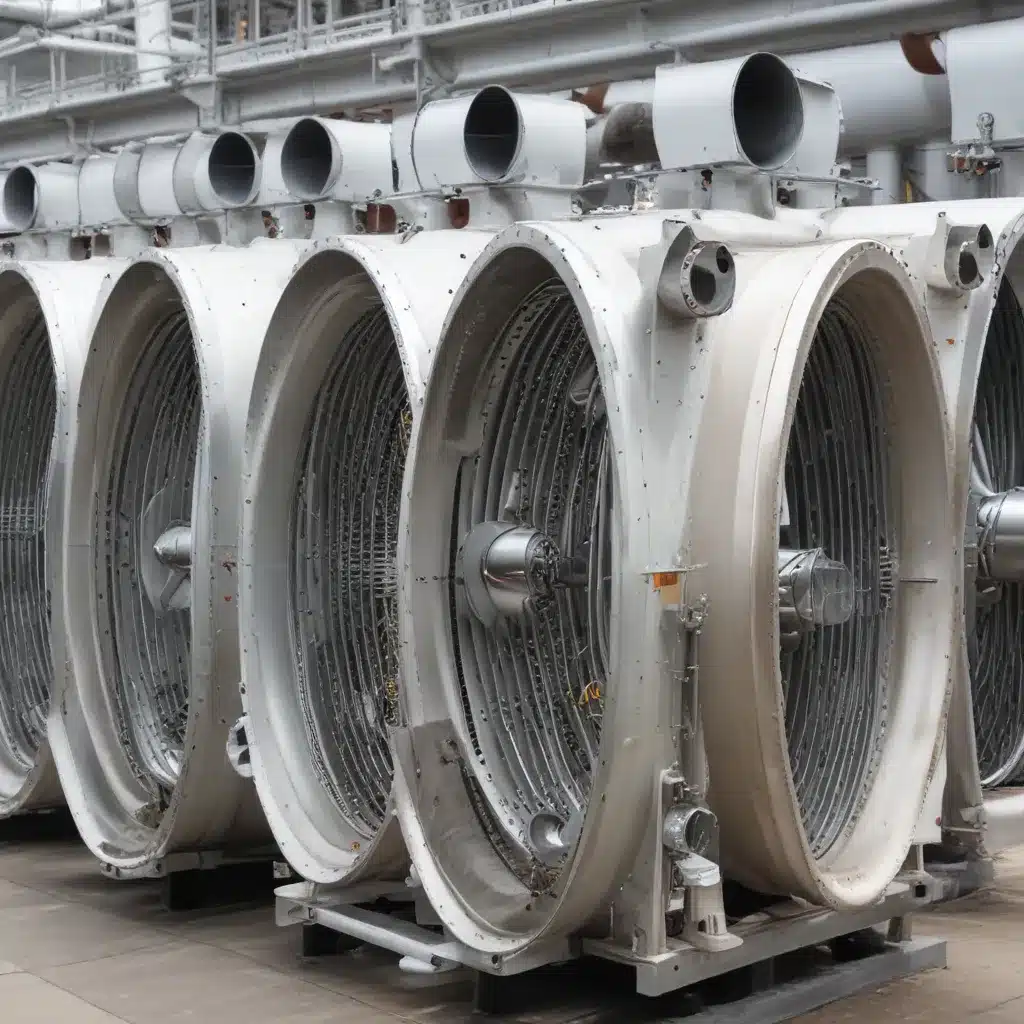

Heat exchangers are essential components in thermal engineering, playing a crucial role in promoting energy efficiency and optimal heat transfer. Among the diverse range of heat exchanger designs, air-cooled heat exchangers stand out for their unique advantages and widespread applications across various industries.

At the core of an air-cooled heat exchanger is the fundamental principle of “conjugate heat transfer” – the transfer of heat from a hot fluid or solid surface to a cooler surface. This heat exchange occurs through indirect contact between the fluids, without any direct mixing. Air-cooled heat exchangers leverage the ubiquitous availability of ambient air to facilitate this thermal energy transfer, making them an energy-efficient and environmentally-friendly solution.

One of the key advantages of air-cooled heat exchangers is their simple yet effective design. Unlike water-cooled systems that require complex water circulation and cooling towers, air-cooled exchangers rely on fans or natural convection to circulate the ambient air across the heat transfer surfaces. This streamlined approach results in fewer moving parts, reduced maintenance requirements, and lower operational costs.

Versatile Applications of Air-Cooled Heat Exchangers

The versatility of air-cooled heat exchangers is evident in their widespread adoption across diverse industries. These exchangers are commonly found in:

-

Power Generation: Air-cooled heat exchangers play a critical role in power plants, where they are used to cool turbine exhaust, generator stator windings, and other heat-generating components.

-

Petrochemical Industry: In refineries and petrochemical facilities, air-cooled heat exchangers are utilized for cooling process streams, condensing vapors, and providing thermal management for various unit operations.

-

Refrigeration and HVAC Systems: Air-cooled condensers and evaporators are integral components in refrigeration and air conditioning systems, ensuring efficient heat dissipation and cooling.

-

Automotive and Aerospace: Air-cooled heat exchangers are extensively used in radiators, oil coolers, and other thermal management systems for vehicles and aircraft.

-

Data Centers: The growing demand for energy-efficient cooling solutions has led to the adoption of air-cooled heat exchangers in data centers, where they effectively dissipate the heat generated by servers and other IT equipment.

-

Food and Beverage Processing: Air-cooled heat exchangers find applications in food processing, dairy, and beverage industries, where they are used for cooling, heating, and temperature control of various products.

These diverse applications demonstrate the versatility of air-cooled heat exchangers in tackling a wide range of thermal engineering challenges, from power generation and industrial processes to high-tech facilities and consumer products.

Design Configurations and Performance Optimization

Air-cooled heat exchangers can be classified based on their flow configurations, each offering unique advantages:

-

Parallel Flow: In this configuration, the hot and cold fluids flow in the same direction within the heat exchanger. While slightly less efficient than counterflow designs, parallel flow exchangers are often simpler in construction and more compact, making them suitable for applications with space constraints.

-

Counterflow: In a counterflow heat exchanger, the hot and cold fluids flow in opposite directions, maximizing the temperature difference between them and enhancing the overall heat transfer efficiency.

-

Crossflow: Crossflow heat exchangers feature a perpendicular arrangement of the fluid streams, allowing for a balance between thermal efficiency and compact design. One fluid flows through the tubes, while the other flows over the external surface of the tubes.

To further optimize the performance of air-cooled heat exchangers, various design features and enhancement techniques are employed:

- Finned Tubes: The addition of external fins significantly increases the surface area available for heat transfer, improving the exchanger’s efficiency and thermal capacity.

- Baffles and Turbulators: Strategic placement of baffles and turbulators within the heat exchanger promotes fluid turbulence, enhancing heat transfer rates.

- Material Selection: The choice of materials with high thermal conductivity, such as aluminum or copper, contributes to the overall heat transfer performance.

- Airflow Optimization: Careful design of the air inlet and outlet configurations, as well as the use of variable-speed fans, can optimize the airflow and improve the heat dissipation capabilities.

Maintenance and Troubleshooting Strategies

Ensuring the reliable and efficient operation of air-cooled heat exchangers requires proactive maintenance and vigilant troubleshooting. Some key maintenance practices include:

-

Regular Cleaning: Periodic cleaning of the heat exchanger surfaces, fins, and air-side components is essential to prevent the buildup of dust, debris, or biological fouling, which can impede airflow and reduce heat transfer performance.

-

Inspection and Monitoring: Regularly inspecting the heat exchanger for signs of corrosion, leaks, or mechanical damage, and monitoring key performance indicators like pressure drops and heat transfer rates, can help identify issues early and prevent costly breakdowns.

-

Proactive Maintenance: Implementing a preventive maintenance program, such as scheduled inspections, component replacements, and selective upgrades, can extend the service life of air-cooled heat exchangers and ensure their optimal performance.

-

Airflow Optimization: Maintaining the proper airflow through the heat exchanger is crucial. This may involve adjusting fan speeds, clearing obstructions, or addressing issues related to the air inlet and outlet configurations.

-

Thermal Performance Optimization: Analyzing the heat exchanger’s thermal performance, such as monitoring temperature profiles and identifying hot spots, can help inform design improvements or suggest operational adjustments to enhance efficiency.

By adopting these maintenance and troubleshooting strategies, operators can ensure the reliable and long-term performance of their air-cooled heat exchangers, maximizing the return on investment and minimizing downtime.

Advancements in Air-Cooled Heat Exchanger Design and Engineering

The field of air-cooled heat exchanger design and engineering is continually evolving, with advancements in materials, manufacturing techniques, and computational tools driving innovation.

One such advancement is the application of Artificial Intelligence (AI) in the design and optimization of air-cooled heat exchangers. By leveraging machine learning algorithms and deep learning techniques, engineers can now analyze the complex relationships between heat exchanger geometries, flow patterns, and thermal performance. This data-driven approach allows for the generative design of air-cooled heat exchangers, where the optimal configuration is derived based on performance criteria, material constraints, and manufacturing considerations.

Furthermore, the integration of computational fluid dynamics (CFD) and finite element analysis (FEA) into the design process has enabled more accurate and comprehensive modeling of air-cooled heat exchanger performance. These numerical simulation techniques provide deeper insights into the fluid dynamics, heat transfer mechanisms, and structural integrity of these critical thermal engineering components.

As the demand for energy-efficient and environmentally-conscious solutions continues to grow, the future of air-cooled heat exchangers is poised to see further advancements, such as the incorporation of advanced materials, innovative geometric designs, and integrated smart monitoring systems. These developments will undoubtedly enhance the performance, reliability, and sustainability of air-cooled heat exchangers, solidifying their pivotal role in the world of thermal engineering.

Conclusion

Air-cooled heat exchangers have emerged as a versatile and indispensable component in the realm of thermal engineering. Their efficient use of ambient air, simple design, and low maintenance requirements have made them a preferred choice across diverse industries, from power generation and petrochemicals to refrigeration and data centers.

By understanding the fundamental principles, design configurations, and performance optimization techniques of air-cooled heat exchangers, engineers and industry professionals can leverage these versatile thermal management solutions to tackle complex thermal engineering challenges. Moreover, the ongoing advancements in materials, manufacturing, and computational tools are poised to unlock new possibilities in the design and deployment of air-cooled heat exchangers, further enhancing their efficiency, reliability, and sustainability.

As the demand for energy-efficient and environmentally-conscious technologies continues to grow, air-cooled heat exchangers will undoubtedly remain at the forefront of thermal engineering, playing a pivotal role in shaping a more sustainable future.