Harnessing Nature’s Genius for Sustainable Engineering

In the relentless pursuit of innovation, engineers and designers have long sought inspiration from the natural world. This approach, known as biomimicry, holds immense promise for revolutionizing the field of air-cooled heat exchangers, particularly in the demanding and high-stakes arena of aerospace applications.

Air-cooled heat exchangers play a crucial role in the aerospace industry, responsible for managing the thermal loads generated by onboard electronics, engines, and other critical systems. As these systems become increasingly powerful and compact, the need for efficient and reliable cooling solutions has never been more paramount. Biomimicry offers a compelling path forward, empowering engineers to unlock the hidden potential of nature’s elegant and time-tested design principles.

Lessons from Nature: Optimizing Air-Cooled Heat Exchanger Design

The natural world is teeming with examples of ingenious thermal management strategies, many of which can be applied to the design of air-cooled heat exchangers. By observing and understanding these natural phenomena, engineers can harness the wisdom of evolution to create innovative solutions that surpass the limitations of conventional approaches.

Harnessing the Efficiency of Termite Mounds

One of the most striking examples of biomimicry in action can be found in the Eastgate Centre, a landmark building in Harare, Zimbabwe. Designed by architect Mick Pearce, the Eastgate Centre draws inspiration from the intricate ventilation system of termite mounds, which maintain a constant internal temperature through passive cooling.

Termite mounds are characterized by a network of internal flues and chimneys that effectively regulate airflow, with the mound’s orientation and shape optimized to capture prevailing winds. This natural ventilation system is remarkably efficient, using minimal energy to maintain a comfortable temperature within the mound.

By emulating the design principles of termite mounds, the Eastgate Centre achieves a similar level of passive cooling, reducing its energy consumption by up to 90% compared to a conventionally cooled building of similar size. This powerful demonstration highlights the immense potential of biomimicry in creating high-performance, energy-efficient air-cooled heat exchangers for aerospace applications.

Microstructural Inspiration: Lotus Leaves and Self-Cleaning Surfaces

Another fascinating example of nature-inspired design can be found in the unique surface properties of lotus leaves. These leaves are renowned for their remarkable water-repellent and self-cleaning abilities, thanks to the microscopic bumps and waxy coatings on their surfaces.

This natural phenomenon, known as the “lotus effect,” has inspired the development of innovative coatings and surface treatments for air-cooled heat exchangers. By replicating the micro- and nano-scale structures found on lotus leaves, engineers have created self-cleaning surfaces that can repel dirt, dust, and other contaminants, improving the heat transfer efficiency and reducing the need for maintenance.

In the aerospace industry, where even minor impurities can severely impact performance, biomimetic self-cleaning surfaces offer a compelling solution. By preventing the buildup of debris and ensuring consistent heat dissipation, these nature-inspired designs can enhance the reliability and longevity of air-cooled heat exchangers, delivering tangible benefits to aerospace applications.

Streamlining with Biological Inspiration

The elegantly streamlined shapes of animals like birds and fish have long inspired the design of high-speed vehicles and aircraft. In the context of air-cooled heat exchangers, these biological forms can provide valuable insights into optimizing airflow and minimizing drag.

Engineers have observed that the aerodynamic profiles of bird beaks and fish bodies can significantly reduce turbulence and improve air or fluid flow around a surface. By incorporating these bioinspired shapes and features into the design of air-cooled heat exchanger fins and housings, designers can achieve enhanced heat transfer rates, lower pressure drops, and improved overall efficiency.

The iconic Shinkansen bullet train, for example, drew inspiration from the beak of the kingfisher bird to reduce noise and increase speed, demonstrating the power of biomimicry in transportation design. Similarly, air-cooled heat exchangers can benefit from these nature-inspired aerodynamic principles, leading to enhanced thermal management capabilities and better performance in aerospace applications.

Additive Manufacturing and Biomimicry: A Powerful Synergy

The rise of additive manufacturing (AM) has revolutionized the way engineers can approach the design and fabrication of air-cooled heat exchangers. By leveraging the flexibility and geometric freedom offered by 3D printing, designers can now realize intricate, biomimetic structures that would be impossible to achieve through traditional manufacturing methods.

Unlocking Complex Geometries

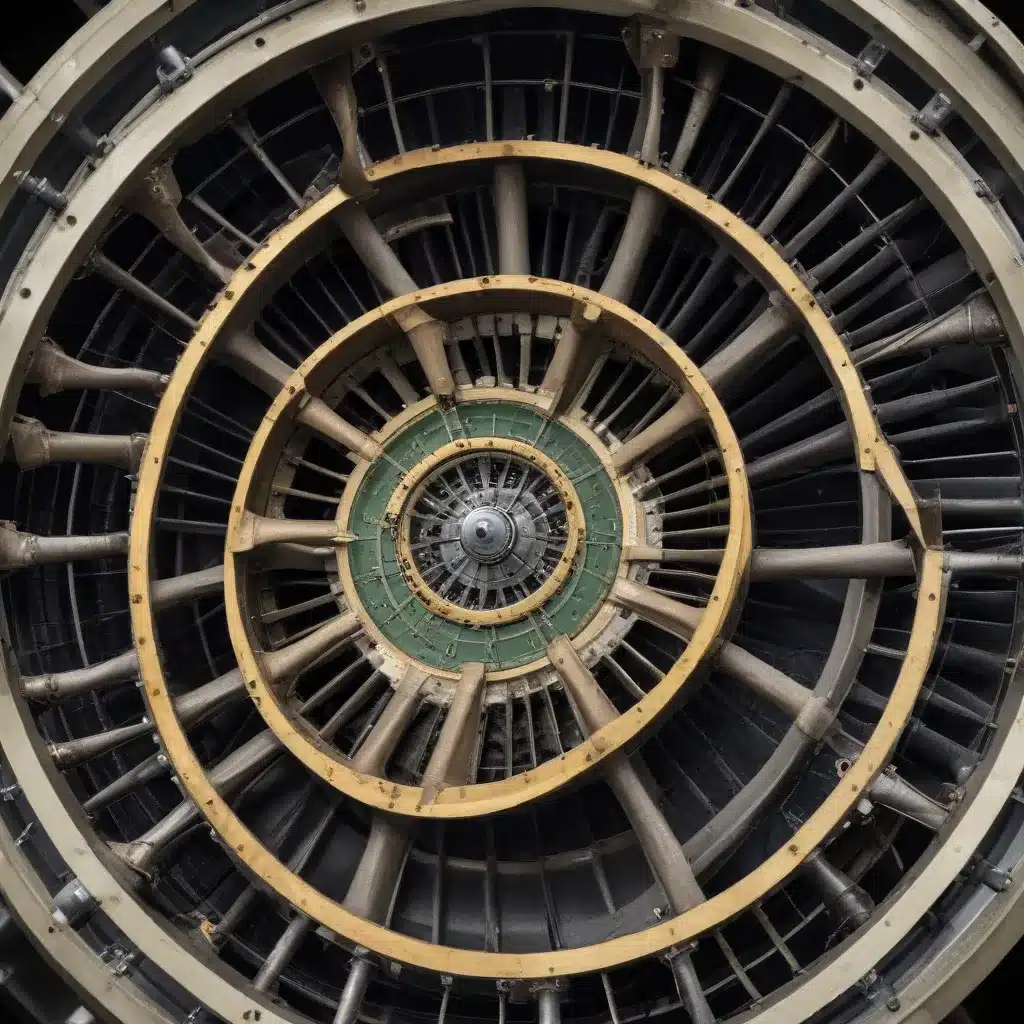

Additive manufacturing allows for the creation of complex, multi-scale structures that mimic the intricate designs found in nature. From the branching patterns of trees to the honeycomb-like structures of beehives, AM enables the fabrication of heat exchanger components with bioinspired geometries that can significantly enhance heat transfer and airflow.

These biomimetic designs often feature intricate, three-dimensional networks of channels, fins, and passages that closely resemble the efficient fluid transport systems observed in living organisms. By replicating these natural designs, engineers can create air-cooled heat exchangers with increased surface area, improved heat dissipation capabilities, and reduced pressure drops – all of which are critical factors in aerospace applications.

Tailoring Material Properties

Biomimicry not only influences the structural design of air-cooled heat exchangers but can also inspire the selection and optimization of materials. The natural world is teeming with examples of composite structures, from the hierarchical arrangements of cellulose and lignin in plant cell walls to the intricate layering of chitin and protein in insect exoskeletons.

Additive manufacturing enables the creation of advanced composite materials that mimic these natural designs, combining the unique properties of different constituent materials to achieve superior thermal, mechanical, and structural performance. By strategically placing and orienting these bioinspired composites within air-cooled heat exchanger components, engineers can optimize heat transfer, reduce weight, and enhance overall reliability.

Embracing Multifunctionality

One of the hallmarks of natural systems is their inherent multifunctionality, where a single structure or feature serves multiple purposes. This principle can be applied to the design of air-cooled heat exchangers, with biomimicry inspiring the development of components that seamlessly integrate various functionalities.

For example, a heat exchanger fin inspired by the structure of butterfly wings could not only enhance heat transfer but also incorporate self-cleaning properties, reducing maintenance requirements. Similarly, the incorporation of piezoelectric or thermoelectric materials, inspired by the energy-harvesting capabilities of certain organisms, could enable air-cooled heat exchangers to generate electrical power from the waste heat they dissipate.

By embracing the multifunctional nature of biomimetic designs, engineers can create air-cooled heat exchangers that are more efficient, versatile, and adaptable to the ever-evolving needs of the aerospace industry.

Overcoming Challenges and Barriers

While the potential of biomimicry in air-cooled heat exchanger design is undeniable, the implementation of these nature-inspired solutions is not without its challenges. Overcoming these barriers will be crucial for the widespread adoption of biomimetic technologies in the aerospace sector.

Interdisciplinary Collaboration

Effective biomimicry requires a deep understanding of both engineering principles and the natural world. Bridging the gap between biologists, materials scientists, and thermal engineers is essential for identifying the most promising biomimetic strategies and translating them into practical, high-performance solutions.

Fostering interdisciplinary collaboration and knowledge-sharing will be crucial for facilitating the cross-pollination of ideas and accelerating the development of biomimetic air-cooled heat exchangers. Initiatives that bring together experts from diverse backgrounds can help overcome disciplinary silos and drive innovation.

Scalability and Manufacturing Challenges

While additive manufacturing has unlocked new possibilities for realizing complex, biomimetic designs, scaling up these technologies for large-scale production remains a challenge. Ensuring the consistency, reliability, and cost-effectiveness of biomimetic air-cooled heat exchangers will be critical for their widespread adoption in the aerospace industry.

Addressing these scalability issues will require continuous improvements in additive manufacturing processes, material development, and automation technologies. Collaboration with industry partners and research institutions can help identify and overcome these manufacturing hurdles, paving the way for the seamless integration of biomimetic solutions into aerospace applications.

Testing and Certification

The aerospace industry is known for its stringent safety and performance standards, which poses a unique challenge for the introduction of novel, biomimetic technologies. Comprehensive testing and rigorous certification processes are essential to ensure the reliability, durability, and safety of air-cooled heat exchangers in demanding aerospace environments.

Developing robust testing protocols and working closely with regulatory bodies will be crucial for demonstrating the viability and reliability of biomimetic air-cooled heat exchangers. This process will require a deep understanding of the underlying principles, thorough performance evaluation, and a strong commitment to addressing any potential concerns or risks.

Unlocking the Future of Aerospace Thermal Management

As the aerospace industry continues to push the boundaries of technological innovation, the pivotal role of air-cooled heat exchangers in enabling these advancements cannot be overstated. By embracing the principles of biomimicry and leveraging the capabilities of additive manufacturing, engineers can unlock a new era of high-performance, sustainable, and adaptable thermal management solutions.

The journey ahead may be filled with challenges, but the rewards are immense. By harnessing the wisdom of nature, designers can create air-cooled heat exchangers that surpass the limitations of conventional approaches, delivering enhanced efficiency, reliability, and versatility – all of which are essential for the demanding requirements of the aerospace industry.

As we continue to explore the wonders of the natural world and push the boundaries of human ingenuity, the integration of biomimicry into air-cooled heat exchanger design stands as a testament to the power of innovation and the enduring inspiration that nature provides. The future of aerospace thermal management is bright, and it is in our hands to unlock its full potential.