In the ever-evolving landscape of thermal engineering, air-cooled heat exchangers have emerged as a critical component in a wide range of industries, from power generation and petrochemicals to HVAC systems and industrial processes. As the demand for energy-efficient and environmentally friendly solutions continues to grow, mastering the art of air-cooled heat exchanger design, optimization, and maintenance has become increasingly crucial.

Understanding the Dynamics of Air-Cooled Heat Exchangers

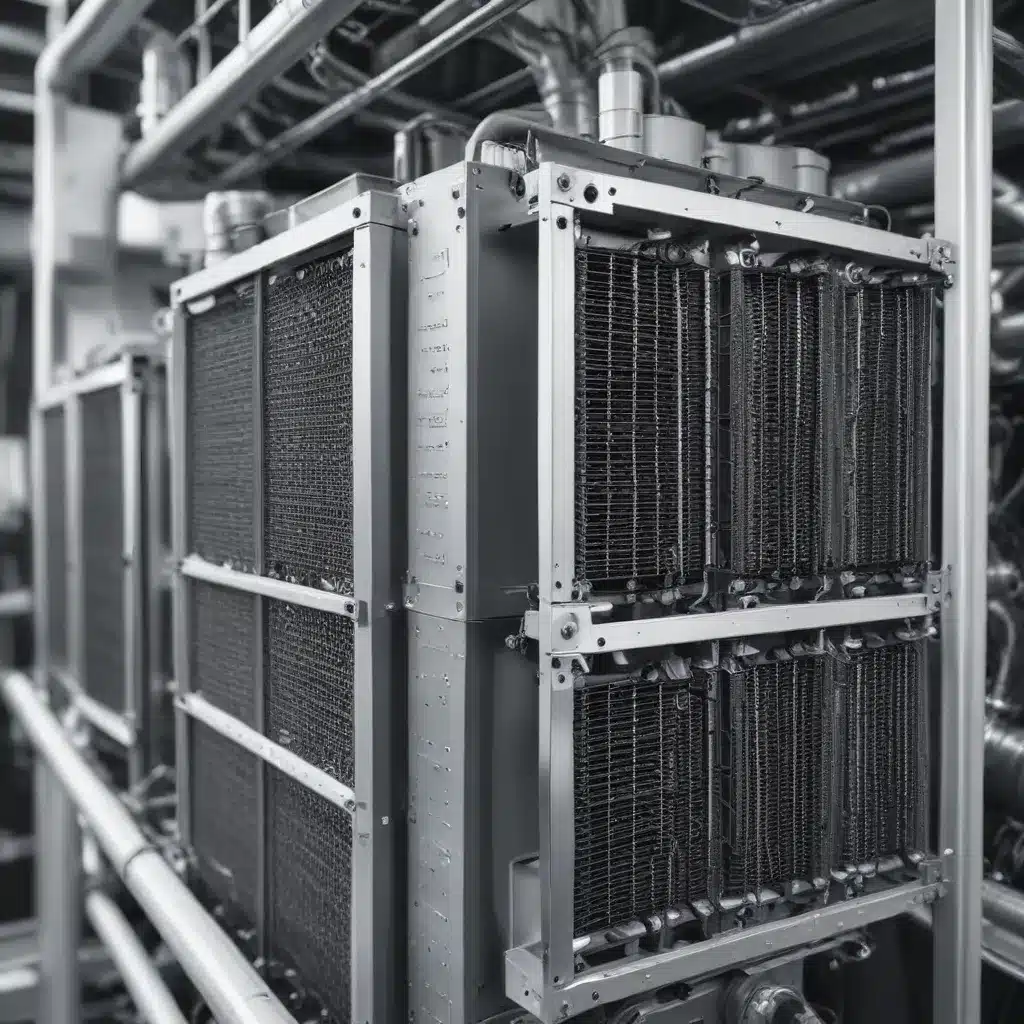

Air-cooled heat exchangers rely on the principles of convective heat transfer to dissipate thermal energy. These systems leverage the abundant availability of air as a cooling medium, making them a popular choice in applications where water or other coolants are scarce or costly. The performance of an air-cooled heat exchanger is influenced by a multitude of factors, including the geometry of the heat transfer surfaces, the airflow characteristics, the properties of the working fluids, and the ambient environmental conditions.

Maintaining optimal performance in air-cooled heat exchangers can be a complex challenge, as these systems are susceptible to various operational and environmental variables. Factors such as fouling, corrosion, and changes in airflow patterns can significantly impact the overall efficiency and reliability of the heat exchanger. Addressing these issues through traditional maintenance approaches can be time-consuming, labor-intensive, and often reactive in nature.

Harnessing the Power of Machine Learning for Performance Optimization

In the quest to enhance the efficiency and reliability of air-cooled heat exchangers, the integration of machine learning (ML) techniques has emerged as a promising solution. By leveraging the vast amounts of data generated by these systems, ML algorithms can help identify patterns, detect anomalies, and predict future performance, enabling proactive maintenance and optimization strategies.

Predictive Maintenance and Fault Detection

One of the key applications of ML in air-cooled heat exchanger systems is predictive maintenance. By analyzing historical data on operational parameters, maintenance records, and environmental conditions, ML models can detect early signs of degradation or potential failures. This allows operators to take proactive measures, such as targeted cleaning, repairs, or component replacements, before catastrophic issues arise. Additionally, ML-based fault detection can help identify and diagnose the root causes of performance issues, enabling more effective troubleshooting and maintenance planning.

Optimizing Heat Exchanger Design and Airflow

Machine learning can also play a crucial role in the design and optimization of air-cooled heat exchangers. By leveraging computational fluid dynamics (CFD) simulations and experimental data, ML algorithms can help identify the most efficient heat exchanger geometries, fin designs, and airflow configurations. This can lead to significant improvements in thermal performance, reduced energy consumption, and enhanced overall system reliability.

Adaptative Controls and Predictive Analytics

In the context of air-cooled heat exchanger operations, ML-driven adaptive controls can respond to dynamic changes in ambient conditions, load requirements, and other variables, ensuring optimal performance at all times. By continuously learning from system data, these control algorithms can make real-time adjustments to parameters such as fan speeds, airflow patterns, and coolant flow rates, maximizing the overall efficiency and energy savings.

Moreover, predictive analytics powered by ML can help operators anticipate future performance trends, allowing for proactive maintenance planning and informed decision-making. By forecasting factors like fouling rates, heat transfer degradation, and equipment lifespan, organizations can optimize their maintenance schedules, minimize operational disruptions, and extend the service life of their air-cooled heat exchangers.

Implementing ML-Driven Performance Optimization

Implementing ML-based performance optimization for air-cooled heat exchangers requires a systematic approach that combines domain expertise, data analytics, and advanced modeling techniques. The process typically involves the following steps:

-

Data Acquisition and Preprocessing: Collect and organize relevant operational data, including sensor readings, maintenance logs, and environmental conditions. Ensure data quality, address missing values, and perform necessary transformations to prepare the data for analysis.

-

Feature Engineering: Identify the key parameters that influence the performance of the air-cooled heat exchanger, such as airflow rates, heat transfer coefficients, and fouling levels. Derive additional features from the raw data that can enhance the predictive capabilities of the ML models.

-

Model Development and Training: Select appropriate ML algorithms, such as regression, classification, or time series models, depending on the specific optimization objectives. Train the models using the preprocessed data, fine-tuning hyperparameters and evaluating model performance through cross-validation.

-

Model Deployment and Monitoring: Integrate the trained ML models into the air-cooled heat exchanger control and monitoring systems, enabling real-time performance optimization and predictive maintenance. Continuously monitor model performance and adapt the models as new data becomes available, ensuring the accuracy and relevance of the predictions.

-

Maintenance and Process Optimization: Leverage the insights gained from the ML-driven performance optimization to inform maintenance schedules, identify areas for process improvements, and maximize the overall efficiency and reliability of the air-cooled heat exchanger system.

By following this systematic approach, organizations can harness the power of machine learning to enhance the efficiency, reliability, and sustainability of their air-cooled heat exchanger operations, ultimately driving improved energy savings, reduced maintenance costs, and increased competitiveness in their respective industries.

Case Study: Optimizing Air-Cooled Heat Exchangers in a Power Generation Facility

A leading power generation company recognized the potential of machine learning to optimize the performance of their air-cooled heat exchangers used in the cooling systems of their thermal power plants. The company partnered with a team of thermal engineering experts and data scientists to develop and implement an ML-driven performance optimization solution.

The project began with a comprehensive data collection and integration effort, gathering operational data from sensors, maintenance logs, and environmental monitoring systems across multiple power plant locations. The team then used feature engineering techniques to derive additional metrics, such as fouling rates, air velocity profiles, and heat transfer coefficients, which were critical to the performance optimization model.

By applying a combination of regression and time series forecasting algorithms, the team developed predictive models that could forecast the degradation of heat exchanger efficiency, anticipate maintenance requirements, and recommend optimal operating parameters. These models were then seamlessly integrated into the plant’s control and monitoring systems, enabling real-time performance optimization and proactive maintenance planning.

The results of the ML-driven optimization were impressive. The power generation company reported a 12% increase in the overall energy efficiency of their air-cooled heat exchanger systems, translating to significant cost savings and reduced environmental impact. Additionally, the predictive maintenance capabilities enabled by the ML models helped the company reduce unplanned downtime by 23%, leading to improved reliability and production uptime.

This case study demonstrates the transformative potential of machine learning in enhancing the performance and sustainability of air-cooled heat exchanger systems, particularly in mission-critical industrial applications. By harnessing the power of data-driven insights and adaptive optimization, organizations can unlock new levels of efficiency, reliability, and competitiveness in their thermal engineering operations.

Conclusion

As the demand for energy-efficient and environmentally friendly solutions continues to grow, the role of air-cooled heat exchangers in various industries becomes increasingly critical. By embracing the integration of machine learning techniques, organizations can unlock a new era of performance optimization, predictive maintenance, and adaptive controls for these vital thermal engineering systems.

The strategies and insights presented in this article provide a roadmap for air-cooled heat exchanger experts, thermal engineers, and facility managers to leverage the power of data-driven analytics and optimize the efficiency, reliability, and sustainability of their operations. By incorporating ML-driven performance optimization, organizations can not only achieve immediate cost savings and operational improvements but also future-proof their thermal engineering capabilities, positioning themselves for long-term success in the ever-evolving landscape of industrial processes and energy systems.

To learn more about the latest advancements in air-cooled heat exchanger technology and performance optimization, visit the Air Cooled Heat Exchangers blog. Our team of industry experts is dedicated to providing practical insights, innovative solutions, and cutting-edge research to help you maximize the efficiency and reliability of your heat exchange systems.