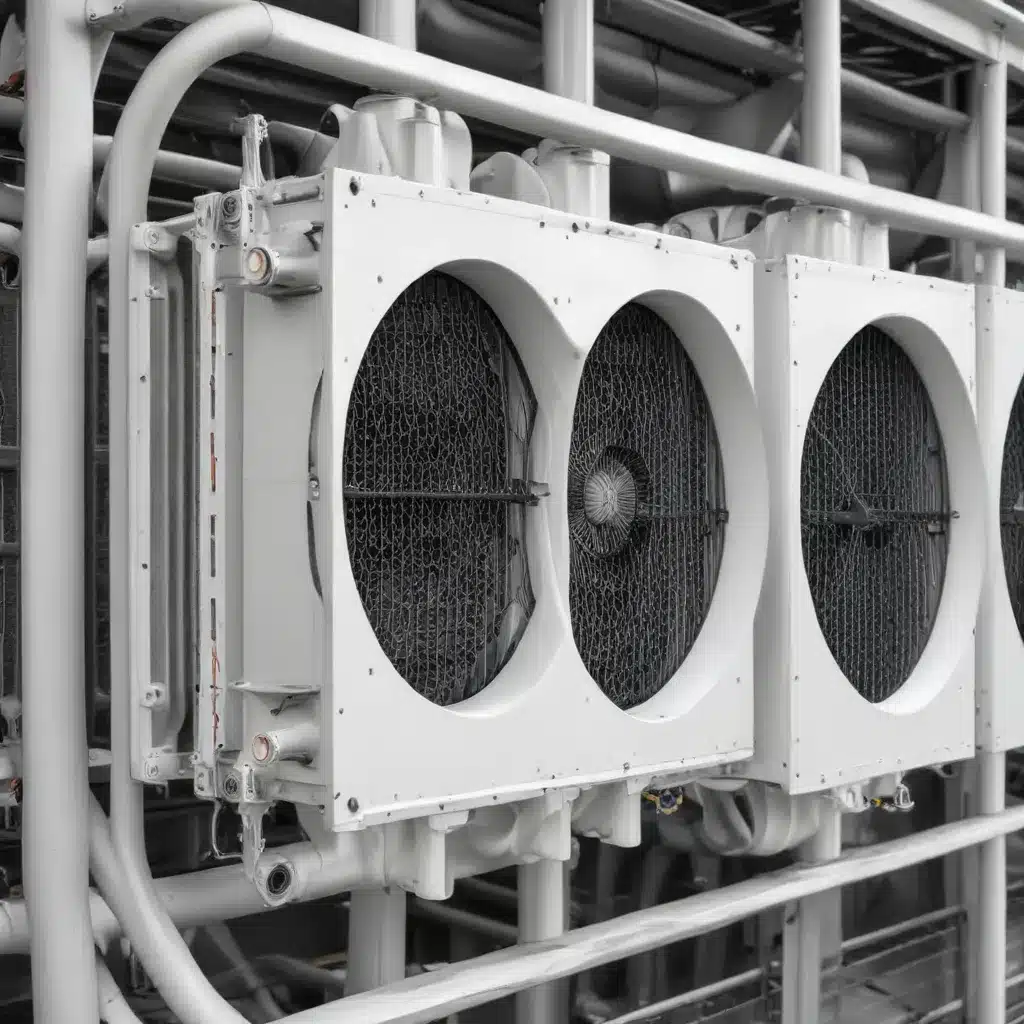

In the rapidly evolving world of industrial and commercial applications, air-cooled heat exchangers have emerged as a versatile and reliable solution for managing thermal loads. As the demand for energy-efficient and high-performance systems continues to grow, the need to optimize the efficiency of these heat exchangers has become paramount. This article will explore innovative airflow management techniques that can significantly enhance the performance of air-cooled heat exchangers, empowering engineers, and plant operators to achieve new levels of operational excellence.

Optimizing Airflow Patterns for Enhanced Heat Transfer

One of the key factors influencing the efficiency of air-cooled heat exchangers is the effective management of airflow patterns. By carefully analyzing and manipulating the airflow, engineers can unlock significant improvements in heat transfer, leading to enhanced overall performance.

Leveraging Computational Fluid Dynamics (CFD) Simulations

Advances in computational fluid dynamics (CFD) have revolutionized the way engineers approach airflow optimization in air-cooled heat exchangers. CFD simulations enable the accurate prediction of airflow patterns, heat distribution, and thermal gradients within the heat exchanger. By utilizing these powerful tools, designers can identify and address potential hotspots, optimize air velocity profiles, and minimize flow disruptions that can compromise efficiency.

Through the application of CFD modeling, engineers can explore innovative airflow management strategies, such as:

-

Streamlining Airflow Pathways: By strategically positioning and shaping the heat exchanger components, the airflow can be directed and channeled to minimize turbulence, reduce pressure drops, and maximize heat transfer coefficients.

-

Implementing Airflow Guides and Baffles: The strategic placement of airflow guides and baffles can control the air’s direction, velocity, and distribution, ensuring a more uniform and efficient heat dissipation process.

-

Enhancing Airside Turbulence: Increasing the turbulence intensity of the airflow can significantly improve convective heat transfer rates, leading to lower surface temperatures and higher overall heat exchanger performance.

By leveraging the insights gained from CFD simulations, engineers can make informed design decisions and optimize the airflow management of air-cooled heat exchangers, ultimately boosting their efficiency and reliability.

Experimental Validation and Optimization

While CFD simulations provide valuable insights, it is essential to validate the computational models through rigorous experimental testing. By conducting wind tunnel experiments and field measurements, engineers can refine their understanding of the heat exchanger’s behavior under various operating conditions, allowing for further optimization of the airflow management strategies.

The experimental validation process typically involves:

-

Wind Tunnel Testing: Subjecting heat exchanger prototypes to controlled airflow conditions in a wind tunnel, allowing for the measurement of temperature distributions, pressure drops, and other key performance indicators.

-

On-Site Measurements: Gathering real-world data from installed air-cooled heat exchangers, including airflow patterns, surface temperatures, and overall thermal performance, to validate the computational models and identify any site-specific considerations.

-

Iterative Design Refinement: Incorporating the insights gained from experimental testing, engineers can further refine the heat exchanger design, modifying airflow pathways, component geometries, and other parameters to achieve optimal performance.

The synergistic integration of CFD simulations and experimental validation enables a comprehensive approach to enhancing the efficiency of air-cooled heat exchangers through innovative airflow management techniques.

Innovative Airflow Management Approaches

Beyond the foundational principles of airflow optimization, several emerging techniques and technologies are transforming the way air-cooled heat exchangers are designed and operated. These innovative approaches can unlock unprecedented levels of efficiency and reliability.

Directed Airflow Configurations

One innovative strategy for improving air-cooled heat exchanger performance is the implementation of directed airflow configurations, such as the front cooling and rear fan setup. This approach strategically positions the cooling fans at the rear of the heat exchanger, while the air inlet is located at the front, effectively channeling the airflow through the heat transfer surfaces.

This directed airflow configuration offers several advantages:

-

Minimized Air Recirculation: By separating the inlet and outlet airstreams, the risk of hot air recirculation and inlet air preheating is significantly reduced, enhancing the overall heat transfer efficiency.

-

Optimized Airflow Distribution: The front cooling and rear fan setup enables a more uniform and controlled airflow distribution across the heat exchanger surfaces, ensuring consistent heat dissipation.

-

Reduced Energy Consumption: The directed airflow design can lead to lower fan power requirements, as the airflow is more efficiently channeled through the heat exchanger, reducing the need for high-velocity air movement.

Airflow Augmentation Techniques

In addition to optimizing the airflow pathways, engineers are exploring various techniques to enhance the airflow itself, leading to improved heat transfer rates and overall heat exchanger performance.

One such approach is the introduction of increased air turbulence. By strategically positioning turbulence-generating elements, such as perforated plates or vortex generators, the airflow can be disrupted, creating higher levels of turbulence intensity. This increased turbulence promotes better mixing of the air within the heat exchanger, leading to enhanced convective heat transfer and lower surface temperatures.

Another innovative technique is the utilization of air jets or impingement cooling. By directing high-velocity air jets onto targeted heat transfer surfaces, the local heat transfer coefficients can be significantly improved, effectively mitigating hot spots and enhancing the overall cooling capacity.

These airflow augmentation techniques, when combined with optimized airflow pathways, can result in substantial improvements in the efficiency and performance of air-cooled heat exchangers.

Hybrid Cooling Approaches

While air-cooled heat exchangers offer numerous advantages, such as simplicity, reliability, and lower maintenance requirements, there are certain applications where their performance may be limited. In these scenarios, hybrid cooling approaches that integrate air-cooling with alternative cooling methods can provide a compelling solution.

One such hybrid approach is the integration of air-cooling with liquid-cooling techniques. By employing a liquid coolant loop in conjunction with the air-cooled heat exchanger, the heat can be efficiently transferred from the process fluid to the liquid coolant, which is then dissipated through the air-cooled heat exchanger. This hybrid configuration can effectively address high-density cooling requirements, often found in industries like electronics, manufacturing, and power generation.

Another hybrid cooling strategy involves the combination of air-cooling with phase-change cooling technologies. By utilizing refrigerants or other phase-change materials, the heat exchanger can leverage the efficient heat transfer associated with phase transitions, while the air-cooling system provides supplementary heat dissipation. This hybrid approach can deliver enhanced cooling capabilities, particularly in applications with fluctuating or unpredictable thermal loads.

The integration of air-cooling with other cooling technologies can unlock new possibilities for air-cooled heat exchangers, expanding their application range and improving their overall performance and efficiency.

Maintenance and Optimization Strategies for Air-Cooled Heat Exchangers

Maintaining the optimal performance of air-cooled heat exchangers is crucial, as it ensures their long-term reliability, energy efficiency, and cost-effectiveness. Proactive maintenance and optimization strategies play a vital role in maximizing the benefits of these heat transfer systems.

Preventive Maintenance Practices

Regularly scheduled maintenance activities are essential for maintaining the efficiency and longevity of air-cooled heat exchangers. Some key preventive maintenance practices include:

-

Airside Cleanliness: Regularly cleaning the heat exchanger surfaces, fins, and air intake areas to remove any accumulated debris, dust, or contaminants that can impede airflow and reduce heat transfer.

-

Fan Inspection and Maintenance: Checking the condition and performance of the cooling fans, ensuring proper airflow, and addressing any issues with fan bearings, motors, or blades.

-

Fouling Monitoring and Mitigation: Implementing regular inspections and monitoring techniques to detect any build-up of deposits or scaling on the heat transfer surfaces, and implementing appropriate cleaning or chemical treatment methods to maintain optimal heat transfer.

-

Vibration Analysis: Monitoring the vibration levels of the heat exchanger and its associated components, as excessive vibration can indicate potential mechanical issues that require attention.

-

Thermal Performance Monitoring: Regularly measuring and tracking the thermal performance of the heat exchanger, such as inlet and outlet temperatures, pressure drops, and overall heat transfer rates, to identify any degradation in efficiency.

By adhering to these preventive maintenance practices, plant operators and maintenance teams can ensure the continued optimal performance of their air-cooled heat exchangers, maximizing their reliability and energy efficiency.

Optimization through Periodic Assessments

In addition to routine maintenance, periodic assessments and optimization efforts can further enhance the performance of air-cooled heat exchangers over their lifetime. These optimization strategies may include:

-

Airflow Optimization Assessments: Conducting periodic CFD simulations and field measurements to evaluate the heat exchanger’s airflow patterns and identify any opportunities for improvement, such as modifying component geometries or implementing airflow guides.

-

Thermal Performance Audits: Performing comprehensive thermal performance audits, including detailed measurements of temperatures, pressures, and heat transfer rates, to identify any degradation in efficiency and develop targeted optimization plans.

-

Retrofit and Upgrade Considerations: Exploring opportunities to retrofit or upgrade existing air-cooled heat exchangers with advanced components, such as more efficient fans, improved coatings, or alternative materials, to boost their overall performance and energy efficiency.

-

Plant Integration Optimization: Evaluating the integration of the air-cooled heat exchanger within the broader plant or system, and making adjustments to improve overall system efficiency, such as optimizing the heat rejection requirements or integrating with other cooling technologies.

By adopting a proactive and data-driven approach to maintenance and optimization, plant operators can ensure that their air-cooled heat exchangers continue to deliver optimal performance, reliability, and cost-effectiveness throughout their service life.

Conclusion

Air-cooled heat exchangers have become an indispensable component in a wide range of industrial and commercial applications, from power generation and manufacturing to HVAC systems and electronics cooling. As the demand for energy-efficient and high-performance heat transfer solutions continues to grow, the importance of innovative airflow management techniques cannot be overstated.

By leveraging computational fluid dynamics, experimental validation, and emerging airflow management approaches, engineers can unlock significant improvements in the efficiency and reliability of air-cooled heat exchangers. From directed airflow configurations and airflow augmentation techniques to hybrid cooling solutions, the advancements in this field are poised to transform the way heat transfer challenges are addressed.

Complementing these innovative design strategies, a comprehensive maintenance and optimization program is essential to ensure the long-term performance and cost-effectiveness of air-cooled heat exchangers. By adopting proactive maintenance practices and periodic assessments, plant operators can maximize the benefits of these critical heat transfer systems, contributing to overall operational excellence and sustainability goals.

As the industry continues to evolve, the insights and strategies outlined in this article will serve as a valuable resource for engineers, plant managers, and industry professionals seeking to enhance the efficiency of their air-cooled heat exchangers. By embracing these cutting-edge techniques, the air-cooled heat exchanger landscape is poised for a new era of improved thermal management, energy efficiency, and sustainable operations.