The Evolving Landscape of Air-Cooled Heat Exchanger Technology

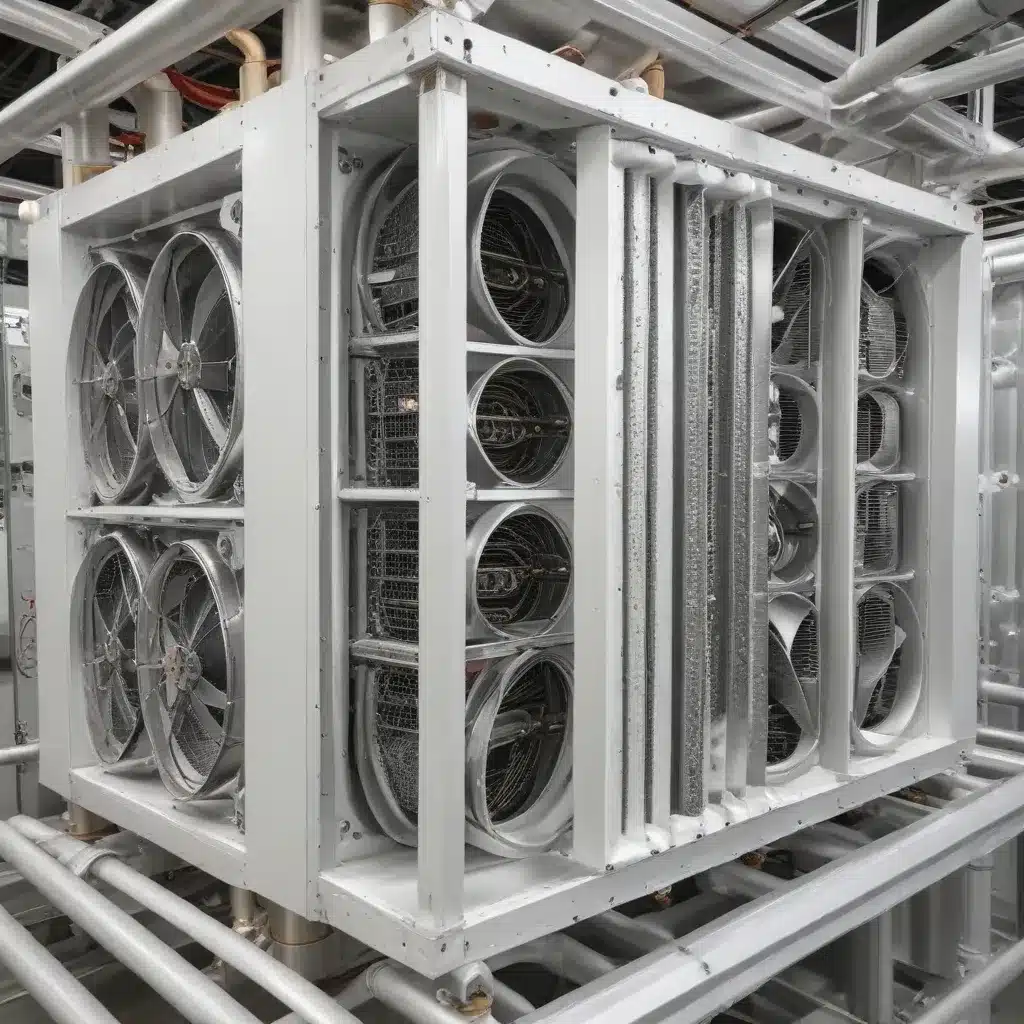

Air-cooled heat exchangers have long been a staple in various industries, playing a pivotal role in thermal management and energy optimization. As the global demand for efficient and eco-friendly cooling solutions continues to rise, the air-cooled heat exchanger industry has witnessed a surge of innovative advancements. From enhanced heat transfer capabilities to improved maintenance protocols and energy-saving designs, these pioneering developments are transforming the way we approach thermal management in critical applications.

Optimizing Heat Transfer Efficiency

One of the primary drivers of innovation in air-cooled heat exchanger design is the relentless pursuit of enhanced heat transfer efficiency. Researchers have explored novel fin geometries, materials, and coatings to maximize the surface area for heat dissipation, ultimately boosting the overall thermal performance of these systems.

Innovative Fin Designs: The introduction of advanced fin configurations, such as wavy, louvered, or serrated fins, has demonstrated significant improvements in heat transfer coefficients compared to traditional straight-fin designs. These intricate fin geometries not only increase the effective surface area but also optimize airflow patterns, leading to more efficient heat exchange.

Composite Materials and Coatings: The use of composite materials, including carbon-fiber-reinforced polymers or metal-matrix composites, has emerged as a game-changer in air-cooled heat exchanger design. These materials offer exceptional thermal conductivity, corrosion resistance, and reduced weight, all of which contribute to enhanced heat transfer and energy efficiency. Moreover, the application of specialized coatings, such as hydrophobic or anti-fouling treatments, can further improve heat exchanger performance by minimizing the detrimental effects of fouling and enhancing heat dissipation.

Advancements in Maintenance and Reliability

Ensuring the long-term reliability and optimal performance of air-cooled heat exchangers is another critical aspect of the industry’s evolution. Maintenance strategies and innovative monitoring technologies have been at the forefront of these advancements.

Predictive Maintenance Protocols: The incorporation of advanced condition monitoring systems, such as vibration analysis, thermal imaging, and online performance tracking, has enabled predictive maintenance approaches. These technologies can detect potential issues before they escalate, allowing for proactive maintenance and minimizing unplanned downtime.

Automated Cleaning Systems: The development of automated cleaning systems, including robotic brushes, ultrasonic vibration, or chemical treatments, has revolutionized the maintenance of air-cooled heat exchangers. These innovative solutions can effectively remove fouling deposits, ensuring optimal heat transfer performance and reducing the burden on maintenance personnel.

Modular Design Innovations: The shift towards modular air-cooled heat exchanger designs has streamlined maintenance and enhanced lifecycle management. Modular components, such as individual fin assemblies or heat exchanger cores, can be easily replaced, reducing downtime and simplifying maintenance tasks.

Energy-Efficient Design Strategies

As the global focus on sustainability and energy conservation intensifies, air-cooled heat exchanger manufacturers have responded with innovative design strategies aimed at reducing energy consumption and improving overall efficiency.

Hybrid Cooling Configurations: The integration of air-cooled heat exchangers with other cooling technologies, such as evaporative cooling or thermal energy storage systems, has led to the development of hybrid cooling solutions. These hybrid systems leverage the strengths of multiple cooling methods, optimizing energy usage and enhancing overall system efficiency.

Variable-Speed Fan Drives: The implementation of variable-speed fan drives in air-cooled heat exchangers has enabled more precise fan control and reduced energy consumption. By adjusting fan speed based on varying heat loads and ambient conditions, these systems can operate at their most efficient point, resulting in significant energy savings.

Innovative Heat Exchanger Geometries: Advancements in computational fluid dynamics (CFD) modeling and experimental testing have facilitated the development of innovative heat exchanger geometries, such as compact, finned-tube, or microchannel designs. These geometries maximize heat transfer while minimizing pressure drop, contributing to improved energy efficiency.

Pioneering Applications of Air-Cooled Heat Exchangers: Balancing Thermal Management and Operational Efficiency

The versatility of air-cooled heat exchangers has made them indispensable across a wide array of industries, each with unique thermal management requirements and operational constraints. Pioneering advancements in this technology have enabled critical applications to achieve optimal thermal performance while prioritizing energy efficiency and sustainability.

Power Generation and Industrial Processes

In the power generation sector, air-cooled heat exchangers play a pivotal role in cooling turbine generators, condensers, and other critical components. The integration of advanced heat exchanger designs and predictive maintenance strategies has been instrumental in enhancing the reliability and efficiency of power plants.

Similarly, in various industrial processes, such as chemical manufacturing, petrochemical refineries, and metal processing, air-cooled heat exchangers are essential for cooling process fluids, lubricants, and waste heat streams. The ability to tailor heat exchanger configurations to specific process requirements and implement energy-efficient cooling solutions has been a game-changer in these industries, contributing to improved productivity, cost savings, and reduced environmental impact.

Data Centers and Telecommunications

The exponential growth of data-driven technologies and the relentless demand for computing power have placed a significant burden on data center cooling systems. Air-cooled heat exchangers have emerged as a preferred solution, providing efficient and reliable thermal management for server racks, power electronics, and other mission-critical infrastructure.

Innovative air-cooled heat exchanger designs, incorporating advanced fin geometries, variable-speed fans, and hybrid cooling configurations, have enabled data centers to optimize energy consumption while maintaining the necessary temperature and humidity conditions for optimal equipment performance and longevity.

Heating, Ventilation, and Air Conditioning (HVAC)

The HVAC industry has long been a prominent adopter of air-cooled heat exchangers, with applications ranging from residential and commercial buildings to industrial facilities. The integration of air-cooled heat exchangers with heat pump systems, chilled water loops, and thermal energy storage has revolutionized HVAC design, allowing for improved energy efficiency, reduced carbon footprint, and enhanced occupant comfort.

Moreover, the advancements in air-cooled heat exchanger technology have enabled the development of high-efficiency HVAC systems, tailored to meet the specific thermal requirements of diverse building types and climates. These innovative solutions are instrumental in driving the transition towards more sustainable and energy-conscious building design.

Automotive and Transportation

The automotive industry has witnessed a surge in the use of air-cooled heat exchangers, particularly in the context of electric and hybrid vehicles. These advanced heat exchangers are integral to the thermal management of battery packs, power electronics, and electric motors, ensuring optimal performance and prolonging the lifespan of critical components.

Furthermore, the transportation sector, including aviation and marine applications, has also leveraged air-cooled heat exchangers for cooling various systems, such as engine coolants, lubricants, and avionics. The development of lightweight, compact, and highly efficient air-cooled heat exchangers has been crucial in addressing the unique challenges posed by these mobile applications, where space and weight constraints are paramount.

Navigating the Challenges and Optimizing Air-Cooled Heat Exchanger Performance

While the advancements in air-cooled heat exchanger technology have been remarkable, the industry still faces various challenges that demand innovative solutions. Addressing these challenges is essential to unlocking the full potential of air-cooled heat exchangers and ensuring their continued relevance in the evolving landscape of thermal management.

Mitigating Fouling and Corrosion

One of the persistent challenges in air-cooled heat exchanger operation is the accumulation of fouling deposits, such as dust, debris, or mineral scaling, on the heat transfer surfaces. This fouling can significantly degrade heat transfer efficiency and increase pressure drop, ultimately impacting the overall system performance.

To address this issue, researchers have explored various strategies, including the development of anti-fouling coatings, self-cleaning mechanisms, and automated cleaning systems. These advancements have been instrumental in maintaining optimal heat transfer rates and extending the service life of air-cooled heat exchangers.

Similarly, corrosion resistance is a crucial consideration, especially in harsh operating environments or when dealing with corrosive process fluids. The selection of appropriate materials, protective coatings, and corrosion-monitoring techniques has been a focus of ongoing research to ensure the long-term reliability and integrity of air-cooled heat exchangers.

Enhancing Heat Transfer Capabilities

While the advancements in fin geometries and materials have led to significant improvements in heat transfer efficiency, there is a continued drive to push the boundaries of air-cooled heat exchanger performance. Researchers are exploring innovative techniques, such as the integration of phase change materials, the use of nanofluids, and the implementation of active flow control mechanisms, to further enhance heat transfer capabilities.

These emerging technologies aim to maximize the heat transfer coefficient, increase the effective heat transfer surface area, and optimize the airflow patterns within the heat exchanger, ultimately enabling more compact and efficient designs.

Addressing Acoustic and Vibration Challenges

Air-cooled heat exchangers, particularly those with high-speed fans, can generate significant noise and vibration, which can pose challenges in various applications, such as urban environments, industrial facilities, or noise-sensitive applications like data centers.

Advancements in fan design, acoustic insulation, and vibration-dampening techniques have been crucial in mitigating these issues. Innovative solutions, including variable-speed fan drives, aerodynamic fan blade profiles, and advanced structural designs, have enabled the development of quieter and more vibration-resistant air-cooled heat exchanger systems.

Optimizing Energy Efficiency and Sustainability

As the global emphasis on energy efficiency and environmental sustainability intensifies, air-cooled heat exchanger manufacturers are under increasing pressure to develop solutions that prioritize energy conservation and reduce the carbon footprint of their products.

The integration of renewable energy sources, such as solar or wind power, with air-cooled heat exchanger systems, as well as the implementation of advanced control algorithms and thermal energy storage, have emerged as promising strategies to enhance the overall sustainability of these systems.

Moreover, the adoption of circular economy principles, including the use of recycled or recyclable materials, the optimization of manufacturing processes, and the extension of product lifecycles, are becoming increasingly important in the air-cooled heat exchanger industry.

Conclusion: Embracing the Future of Air-Cooled Heat Exchanger Technology

The air-cooled heat exchanger industry is at the forefront of innovative thermal management solutions, driven by the relentless pursuit of enhanced performance, energy efficiency, and sustainability. The advancements in fin geometries, materials, maintenance strategies, and hybrid cooling configurations have transformed the landscape, empowering industries to address their unique thermal challenges more effectively.

As we navigate the future, the air-cooled heat exchanger industry is poised to play a pivotal role in supporting critical applications, driving energy savings, and contributing to a more sustainable built environment. By embracing these pioneering advancements and continuously exploring new frontiers, air-cooled heat exchanger technology will continue to be a cornerstone of efficient thermal management, fostering a greener and more energy-conscious future.