Unlocking the Potential of Air-Cooled Heat Exchangers

In the ever-evolving landscape of industrial thermal management, air-cooled heat exchangers have emerged as strategic assets for companies seeking to optimize their processes, enhance energy efficiency, and drive sustainability. As a seasoned expert in this field, I’m excited to share cutting-edge techniques and insights that can help you unlock the full potential of air-cooled heat exchangers.

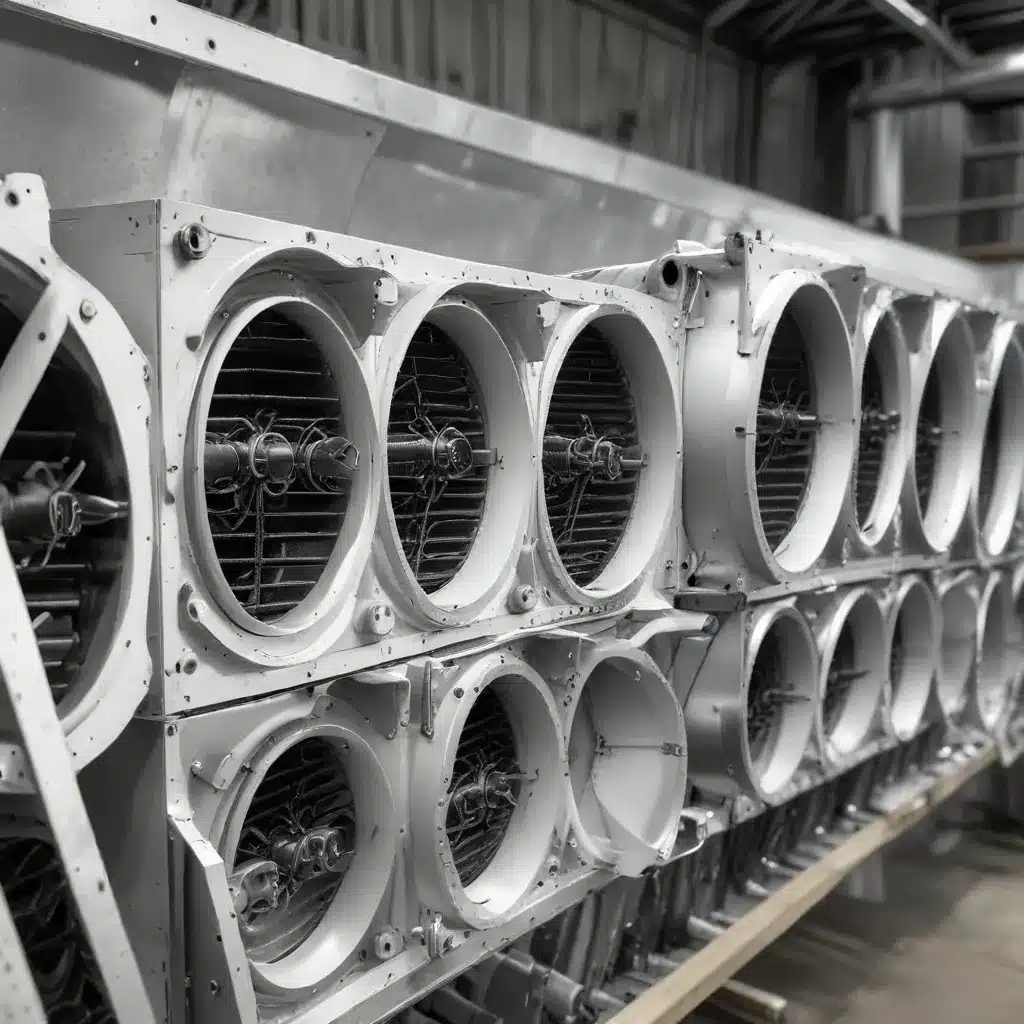

Mastering Heat Transfer Efficiency

The foundation of any high-performing air-cooled heat exchanger lies in its ability to effectively transfer heat between fluids. By leveraging advanced computational fluid dynamics (CFD) simulations and testing, engineers can now design heat exchanger geometries that maximize heat transfer coefficients and minimize pressure drops. This optimization process involves carefully evaluating factors such as fin spacing, tube arrangement, and airflow patterns to achieve the desired level of thermal efficiency.

Tip: Collaborate with heat exchanger manufacturers that utilize state-of-the-art CFD tools and have a proven track record of designing customized solutions tailored to your specific application requirements.

Enhancing Durability and Reliability

Air-cooled heat exchangers often operate in challenging environments, facing exposure to harsh weather conditions, corrosive media, and extreme temperatures. Ensuring the long-term durability and reliability of these critical components is essential for maintaining uninterrupted production and minimizing costly downtime.

One key strategy is to prioritize the selection of high-quality materials, such as corrosion-resistant alloys, that can withstand the rigors of your operating environment. Additionally, innovative coatings and surface treatments can further enhance the resistance of heat exchanger components to wear, erosion, and fouling.

Tip: Engage with heat exchanger suppliers that offer comprehensive testing and quality assurance procedures to validate the durability and performance of their products under real-world conditions.

Optimizing Maintenance and Servicing

Maintaining the optimal performance of air-cooled heat exchangers requires a proactive approach to maintenance and servicing. Develop a comprehensive maintenance plan that incorporates regular inspections, cleaning procedures, and predictive maintenance techniques to identify and address potential issues before they escalate.

Leverage advanced monitoring systems that can continuously track key parameters, such as temperature, pressure, and vibration, to detect early signs of degradation or fouling. By implementing these practices, you can extend the service life of your heat exchangers, minimize unplanned downtime, and reduce maintenance costs.

Tip: Collaborate with heat exchanger service providers that offer comprehensive maintenance programs, including on-site troubleshooting, predictive analytics, and customized repair solutions.

Addressing Industry-Specific Challenges

While the principles of air-cooled heat exchanger optimization apply across various industries, each sector may face unique challenges that require tailored solutions. Let’s explore how these cutting-edge techniques can be applied to address specific needs in select industries.

Power Generation

In the power generation industry, air-cooled heat exchangers play a crucial role in cooling steam turbines, condensers, and other critical components. Enhancing the thermal efficiency of these heat exchangers can significantly improve the overall efficiency of power plants, leading to substantial energy and cost savings.

By leveraging advanced materials and coatings, power generation operators can ensure the durability of air-cooled heat exchangers in the face of corrosive environments, high temperatures, and heavy particulate loads. Additionally, predictive maintenance strategies can help anticipate and address potential issues, minimizing unplanned shutdowns and maximizing plant uptime.

Chemical and Petrochemical Processing

In the chemical and petrochemical industries, air-cooled heat exchangers are essential for maintaining precise temperature control in various processes, such as reactor cooling, distillation, and product cooling. Optimizing the heat transfer efficiency of these exchangers can lead to improved product quality, increased process yields, and reduced energy consumption.

Manufacturers in these sectors often face challenges with fouling and scaling, which can significantly impair heat exchanger performance over time. Implementing innovative cleaning methods, such as automated online cleaning systems, can help maintain optimal heat transfer rates and minimize the need for manual interventions.

HVAC and Refrigeration

The HVAC and refrigeration industries rely heavily on air-cooled heat exchangers to facilitate efficient heating, cooling, and dehumidification processes. Enhancing the reliability and durability of these components is crucial for ensuring the seamless operation of HVAC systems and refrigeration equipment.

By selecting corrosion-resistant materials and incorporating smart monitoring systems, HVAC and refrigeration professionals can proactively address potential issues, such as coil fouling or fan failures, before they disrupt the system’s performance. Additionally, the integration of advanced fan technologies and airflow optimization can further improve the energy efficiency of air-cooled heat exchangers in these applications.

Embracing Sustainable Solutions

As global sustainability efforts gain momentum, the role of air-cooled heat exchangers in reducing environmental impact has become increasingly important. Manufacturers and operators are now prioritizing the development and implementation of eco-friendly solutions that minimize energy consumption, emissions, and resource usage.

One such innovative approach is the integration of heat recovery systems with air-cooled heat exchangers. By capturing and reusing waste heat, these systems can significantly improve the overall energy efficiency of industrial processes, contributing to a more sustainable future.

Additionally, the selection of environmentally friendly refrigerants and the implementation of low-noise, high-efficiency fan technologies can further enhance the environmental performance of air-cooled heat exchangers, making them an integral part of the drive towards greener industrial operations.

Partnering for Success

To fully harness the potential of air-cooled heat exchangers, it is essential to collaborate with industry-leading manufacturers and service providers. These partners can offer a wealth of expertise, cutting-edge technologies, and personalized support to help you overcome your unique challenges and achieve your goals.

Look for heat exchanger suppliers that prioritize innovation, emphasize customized solutions, and demonstrate a deep understanding of your industry’s requirements. By working closely with these partners, you can unlock the true potential of air-cooled heat exchangers, optimizing your thermal management processes, enhancing reliability, and driving sustainable growth.

Visit https://www.aircooledheatexchangers.net/ to explore our comprehensive range of air-cooled heat exchanger solutions and connect with our team of experts. Together, we can embark on a journey of continuous improvement and unlock new possibilities in your thermal management operations.