Understanding the Importance of Air-Cooled Heat Exchangers in Automotive Applications

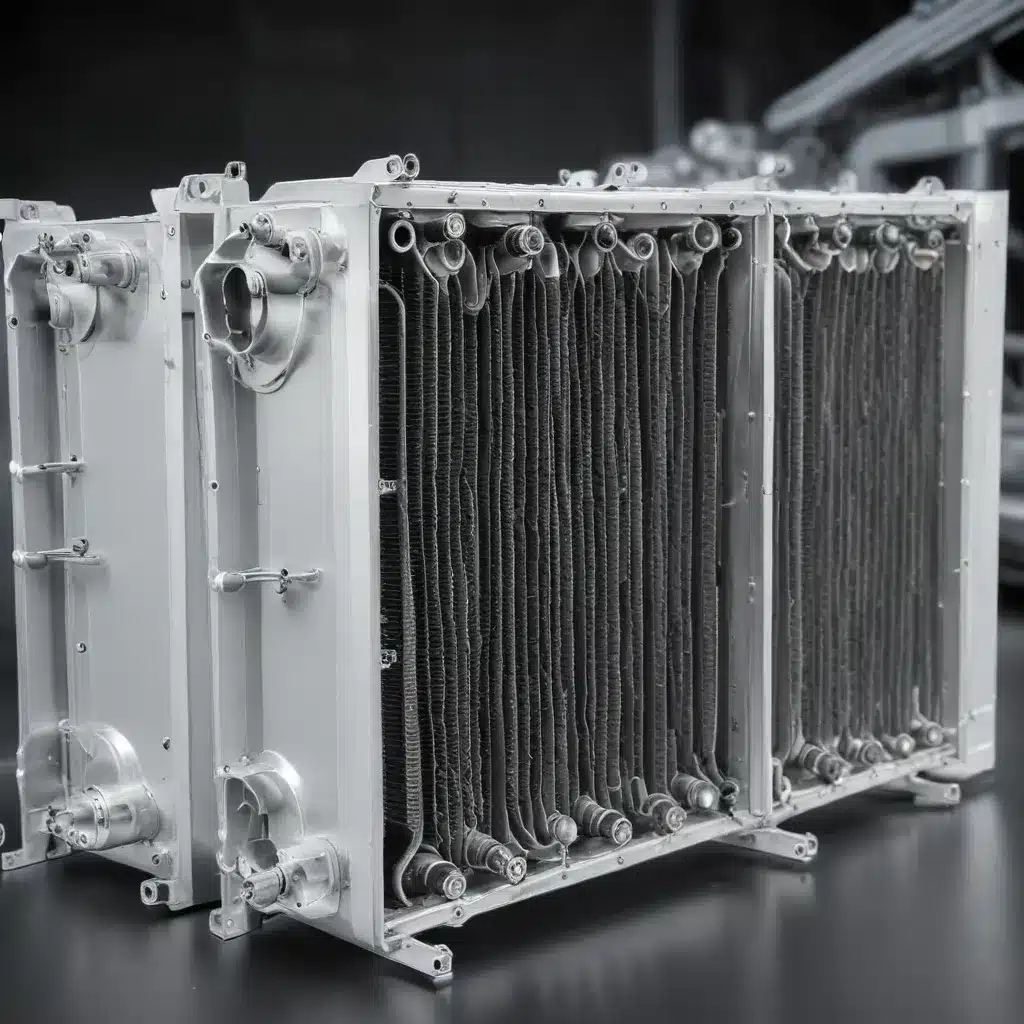

In the ever-evolving automotive industry, thermal management has become a critical aspect of vehicle design and engineering. As manufacturers strive to deliver more efficient, eco-friendly, and high-performing vehicles, the role of air-cooled heat exchangers has become increasingly pivotal. These versatile components play a crucial part in maintaining the optimal temperature of various automotive systems, from powertrain and exhaust gas recirculation to battery and cabin cooling.

The Rise of Hybridization and Electrification

With the growing trend of hybrid and electric vehicles, the demand for advanced thermal management solutions has escalated. Powertrain electrification introduces new challenges, as the heat generated by electric motors, batteries, and power electronics must be efficiently dissipated to ensure optimal performance and longevity. Air-cooled heat exchangers have emerged as key enablers in this transition, providing compact, lightweight, and highly efficient cooling systems that can be seamlessly integrated into the vehicle’s architecture.

Stricter Emissions Regulations and Fuel Economy Standards

Alongside the shift towards electrification, the automotive industry also faces increasingly stringent emissions regulations and fuel economy standards. This has led to the widespread adoption of technologies like exhaust gas recirculation (EGR) to reduce nitrous oxide (NOx) emissions and improve overall engine efficiency. Air-cooled EGR coolers have become a critical component in both diesel and gasoline engine systems, efficiently cooling the recirculated exhaust gas to enhance its density and reduce its volume, ultimately contributing to lower emissions and better fuel economy.

Optimizing Air-Cooled Heat Exchanger Design and Performance

To meet the growing demands of the automotive industry, manufacturers of air-cooled heat exchangers must continuously refine their designs and engineering approaches. A comprehensive understanding of heat transfer principles, fluid dynamics, and material properties is essential in developing high-performance, cost-effective, and packaging-efficient solutions.

Improving Heat Transfer Efficiency

One of the primary focuses in air-cooled heat exchanger optimization is enhancing heat transfer efficiency. This can be achieved through various design strategies, such as:

-

Fin Geometry and Density: Varying the fin shape, thickness, and spacing can significantly impact the heat transfer coefficient and overall thermal performance. Designers often explore different fin configurations, such as louvered, wavy, or serrated fins, to find the optimal balance between heat transfer and pressure drop.

-

Tube Arrangement and Flow Patterns: The arrangement of the heat exchanger tubes, as well as the flow patterns of the air and coolant, can be optimized to maximize heat transfer. Techniques like staggered or inline tube layouts, as well as the use of baffles or flow guides, can enhance the thermal-hydraulic performance.

-

Material Selection: The choice of materials, such as aluminum or copper, can influence the heat transfer characteristics, weight, and manufacturing considerations of the air-cooled heat exchanger. Advanced materials, including coatings or composite structures, may also be explored to further improve performance and durability.

Addressing Packaging and Integration Challenges

Automotive designers face tight packaging constraints and the need for seamless integration of air-cooled heat exchangers into the vehicle’s architecture. Optimizing the design and layout of these components requires careful consideration of factors such as:

-

Compact Footprint: Developing compact, lightweight, and space-efficient heat exchangers that can be positioned strategically within the engine bay or other available spaces is crucial for maintaining optimal vehicle aerodynamics and safety.

-

Modular Design: Modular heat exchanger designs that can be easily customized and adapted to different vehicle platforms and applications can enhance flexibility and reduce development time and costs.

-

Integrated Solutions: Collaborating closely with original equipment manufacturers (OEMs) and component suppliers to integrate air-cooled heat exchangers, such as charge-air coolers or EGR coolers, into the vehicle’s intake manifold or other subsystems can lead to optimized performance and efficient packaging.

Ensuring Durability and Reliability

In the harsh operating environment of automotive applications, air-cooled heat exchangers must demonstrate exceptional durability and reliability to withstand a range of environmental conditions, vibrations, and thermal stresses. Strategies to enhance the longevity and dependability of these components include:

-

Robust Construction: Employing advanced manufacturing techniques, such as controlled atmosphere brazing (CAB) or vacuum brazing, can result in highly durable and corrosion-resistant heat exchanger assemblies.

-

Thermal Cycling and Fatigue Testing: Comprehensive testing and simulation of thermal cycling, shock, and fatigue scenarios can help identify potential weak points and guide the development of more robust designs.

-

Maintenance and Servicing: Providing clear guidelines and recommendations for regular maintenance, cleaning, and inspections can help end-users ensure the long-term performance and reliability of air-cooled heat exchangers throughout the vehicle’s lifecycle.

Innovative Applications and Emerging Trends

As the automotive industry continues to evolve, air-cooled heat exchangers are playing an increasingly pivotal role in addressing new challenges and driving technological advancements.

Thermal Management of Lithium-Ion Batteries

With the widespread adoption of electric and hybrid vehicles, the efficient thermal management of lithium-ion batteries has become a crucial focus area. Air-cooled heat exchangers, often integrated with advanced battery chiller systems, help regulate the battery’s temperature within an optimal operating range, ensuring peak performance, safety, and longevity.

Optimizing Cabin Comfort and Energy Efficiency

Beyond powertrain and drivetrain applications, air-cooled heat exchangers are also essential in maintaining comfortable cabin environments. Integrating these components with the vehicle’s HVAC (Heating, Ventilation, and Air Conditioning) system can help optimize temperature, humidity, and airflow, enhancing passenger comfort while minimizing energy consumption.

Exploring Alternative Cooling Architectures

Innovative cooling architectures, such as the use of liquid-cooled charge-air coolers (LCACs) as an alternative to traditional air-to-air designs, are being explored to further improve power, fuel economy, and emissions performance. These liquid-cooled solutions leverage the enhanced heat transfer properties of coolants, offering greater flexibility and packaging efficiency.

Embracing Simulation and Digital Twins

The development of air-cooled heat exchangers for automotive applications increasingly relies on advanced simulation and digital twin technologies. These tools enable designers to accurately predict thermal behavior, optimize component designs, and validate performance before physical prototyping, ultimately accelerating the product development cycle and reducing overall costs.

Conclusion

As the automotive industry continues to evolve, the role of air-cooled heat exchangers in thermal management has become more critical than ever. By continuously optimizing the design, engineering, and integration of these essential components, manufacturers can meet the growing demands for improved fuel economy, reduced emissions, and enhanced performance across a wide range of vehicle platforms, from traditional internal combustion engines to hybrid and electric powertrains.

Through close collaboration with OEMs, leveraging the latest simulation and testing capabilities, and incorporating innovative design strategies, the air-cooled heat exchanger industry is poised to play a pivotal role in shaping the future of automotive thermal management. By unlocking the full potential of these heat transfer solutions, the industry can contribute to a more sustainable, efficient, and high-performing automotive landscape.

To learn more about the latest advancements in air-cooled heat exchanger technology and how they can benefit your automotive applications, visit https://www.aircooledheatexchangers.net/.