As a seasoned expert in the field of air-cooled heat exchangers, I’ve witnessed the remarkable advancements in thermal management technology over the years. One area that has piqued my interest is the growing influence of microfluidics on the design, efficiency, and versatility of these critical heat transfer systems. In this comprehensive article, we’ll delve into the fascinating world of microfluidics and explore how it is reshaping the performance of air-cooled heat exchangers across various industries.

The Emergence of Microfluidics in Thermal Management

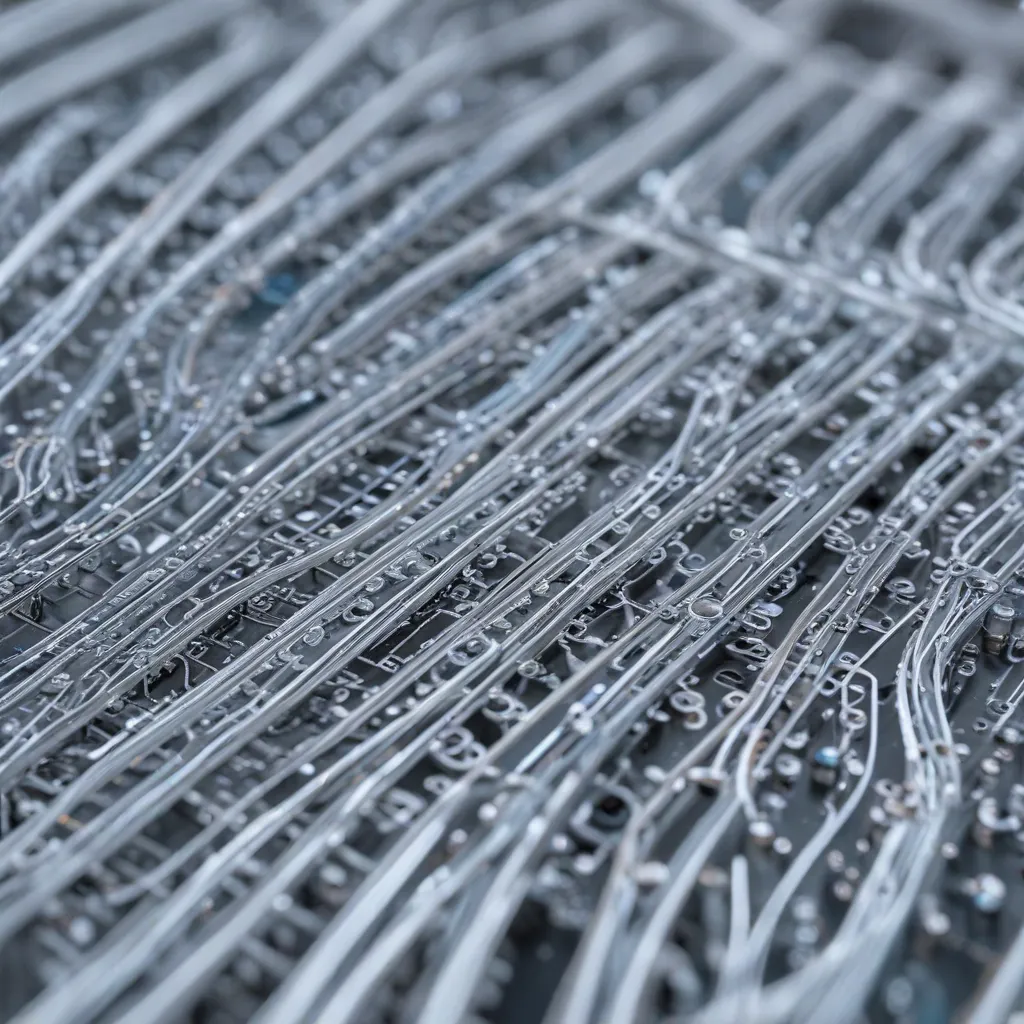

Microfluidics, the study and manipulation of fluids at the microscale, has emerged as a game-changer in the field of thermal engineering. By harnessing the unique properties and behaviors of fluids at the microscale, engineers and researchers have developed innovative solutions to address the ever-increasing demand for efficient and compact cooling systems.

One of the key advantages of microfluidics is its ability to enhance heat transfer rates by leveraging the intricate fluid dynamics at the microscale. At this scale, the surface-to-volume ratio is significantly higher, allowing for more efficient heat dissipation and improved thermal management. Additionally, the precise control over fluid flow and the introduction of micro-scale features, such as micro-channels and micro-pins, can further optimize the heat transfer process.

Enhancing the Thermal Performance of Air-Cooled Heat Exchangers

Air-cooled heat exchangers, widely used in various industrial applications, have long been a subject of continuous improvement and innovation. The integration of microfluidic principles into the design and operation of these heat exchangers has led to remarkable advancements in their thermal performance.

Micro-Channel Heat Exchangers

One prominent application of microfluidics in air-cooled heat exchangers is the development of micro-channel heat exchangers. By incorporating micro-scale channels into the heat exchanger design, engineers can achieve higher heat transfer coefficients and reduced thermal resistance, ultimately leading to enhanced cooling capabilities. The increased surface area-to-volume ratio enabled by these micro-channels allows for more efficient heat dissipation, making micro-channel heat exchangers particularly well-suited for high-power density applications, such as in the electronics and aerospace industries.

Micro-Pin-Fin Heat Exchangers

Another innovative approach is the integration of micro-pin-fin structures into air-cooled heat exchangers. These micro-scale features, strategically placed within the heat exchanger, disrupt the boundary layer and promote turbulent fluid flow, resulting in improved convective heat transfer. The increased heat transfer coefficient, along with the enhanced surface area, contributes to the overall thermal performance enhancement of micro-pin-fin heat exchangers. This design has found applications in high-heat-flux scenarios, such as in the cooling of power electronics and semiconductor devices.

Hybrid Microfluidic Designs

To further optimize the performance of air-cooled heat exchangers, researchers have explored hybrid designs that combine microfluidic principles with other heat transfer enhancement techniques. For instance, integrating micro-channel or micro-pin-fin structures with advanced surface coatings or nanomaterials can lead to synergistic effects, resulting in even higher heat transfer rates and improved thermal management capabilities.

Maintenance and Reliability Considerations

As with any heat transfer system, the maintenance and reliability of air-cooled heat exchangers are crucial factors to consider, especially when integrating microfluidic technologies. The microscale features and intricate fluid dynamics within these systems can introduce unique challenges related to fouling, corrosion, and flow distribution, which must be addressed to ensure long-term performance and operational efficiency.

Regular inspections, preventive maintenance, and the implementation of effective cleaning protocols are essential to mitigate these challenges. Furthermore, the selection of appropriate materials and coatings for the microfluidic components can enhance the overall reliability and durability of the heat exchanger system.

Industrial Applications and Case Studies

The impact of microfluidics on air-cooled heat exchangers extends across various industries, each with its unique thermal management requirements and challenges.

Electronics and Telecommunications

In the fast-paced world of electronics and telecommunications, the demand for efficient cooling solutions has never been higher. Microfluidic-based air-cooled heat exchangers have proven invaluable in the thermal management of high-performance computing systems, data centers, and power electronics, where they enable increased power density and improved reliability.

A case study from Sandia National Laboratories highlights the development of a novel air-cooled heat exchanger that leverages microfluidic principles to achieve a 30% improvement in cooling capacity compared to traditional designs.

Automotive and Aerospace

In the automotive and aerospace industries, where weight, size, and performance are critical factors, microfluidic air-cooled heat exchangers have emerged as a promising solution. These compact and lightweight heat transfer systems can efficiently cool high-heat-flux components, such as electric motors, power electronics, and avionics, while maintaining compact overall system design.

A research paper published in the Journal of Cleaner Production explores the use of micro-channel heat exchangers in the cooling of electric vehicle batteries, highlighting their potential to improve thermal management and extend battery life.

Process Industries and Energy Systems

The process industries, which include chemical, petrochemical, and power generation, have also benefited from the integration of microfluidics in air-cooled heat exchangers. In these applications, the enhanced heat transfer capabilities and improved thermal management offered by microfluidic technologies can lead to increased efficiency, reduced energy consumption, and better process control.

A recent study published in the journal Renewable and Sustainable Energy Reviews investigates the use of micro-pin-fin air-cooled heat exchangers in concentrated solar power plants, demonstrating their potential to improve system performance and reduce the environmental impact of energy generation.

Exploring the Future of Microfluidics in Air-Cooled Heat Exchangers

As we continue to push the boundaries of thermal management, the integration of microfluidics into air-cooled heat exchangers holds immense promise. From enhancing cooling capabilities and improving energy efficiency to enabling compact and lightweight designs, the impact of this synergistic approach is set to redefine the future of air-cooled heat exchanger technology.

At Air Cooled Heat Exchangers, we remain at the forefront of these advancements, continuously exploring the latest research, conducting in-depth analyses, and providing practical insights to our readers. By staying informed and embracing the transformative potential of microfluidics, we can collectively unlock new frontiers in thermal management and drive innovation across diverse industries.