In the bustling world of industrial operations, the quest for efficiency is never-ending. Air Cooled Heat Exchangers (ACHEs) have become a pivotal component in this pursuit, offering game-changing solutions that revolutionize industrial processes. As a seasoned expert in this field, I’m excited to share insights that will empower you to harness the full potential of these innovative systems.

Mastering the Fundamentals of Air-Cooled Heat Exchangers

At the core of industrial efficiency lies the art of heat management. ACHEs play a crucial role in this domain, serving as the unsung heroes of thermal engineering. These remarkable systems utilize the power of air to dissipate excess heat, ensuring that mission-critical equipment and processes operate within safe temperature ranges.

One of the key advantages of ACHEs lies in their versatility. They can be customized to suit a wide range of industrial applications, from power generation and manufacturing to HVAC systems and beyond. By leveraging the natural process of heat transfer, these exchangers optimize energy consumption, reduce operating costs, and minimize environmental impact.

Understanding the Anatomy of ACHEs

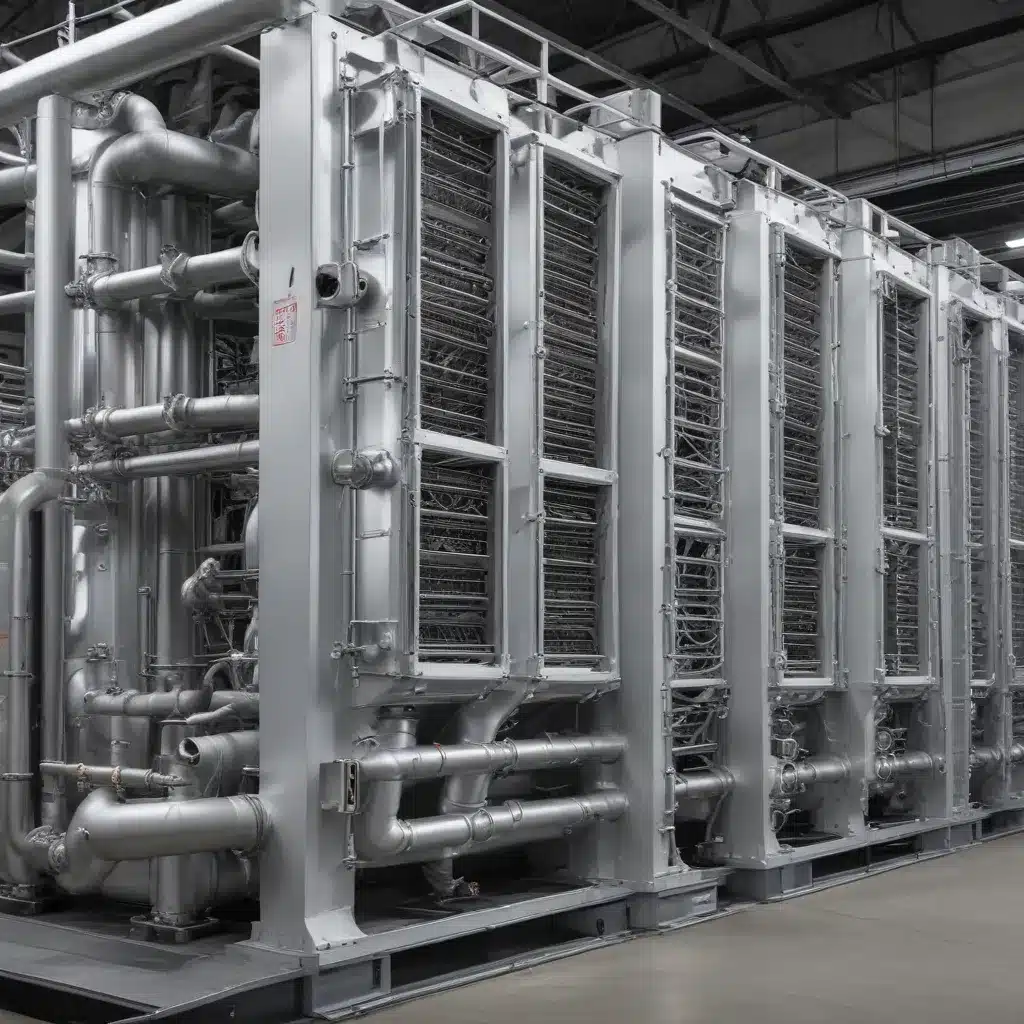

To fully appreciate the capabilities of ACHEs, let’s dive into their intricate design. These systems are typically composed of a series of finned tubes or plates, through which a hot fluid (such as water or oil) flows. As the fluid passes through the exchanger, ambient air is drawn across the fins, effectively transferring the heat from the fluid to the surrounding air.

The design of the heat exchanger plays a crucial role in its overall performance. Factors such as the tube or plate configuration, fin density, and air flow patterns can all contribute to the system’s efficiency. Experts in the field continuously innovate, exploring new materials, geometries, and heat transfer enhancement techniques to push the boundaries of ACHE capabilities.

Optimizing Airflow and Heat Transfer

Airflow management is a fundamental aspect of ACHE optimization. The type of cooling tower employed, whether natural draft or mechanical draft, can have a significant impact on the system’s efficiency. Natural draft towers leverage the natural buoyancy of hot air, while mechanical draft towers use powerful fans to force air through the exchanger.

Equally important is the configuration of the air-fluid flow. Crossflow and counterflow designs offer distinct advantages, catering to varying industrial needs. Crossflow towers, with their horizontal air movement and vertical water flow, excel in ease of maintenance and lower static pressure. Counterflow towers, on the other hand, maximize air-water contact time, resulting in higher thermodynamic efficiency and the ability to handle larger cooling loads.

By meticulously analyzing air and fluid dynamics, engineers can fine-tune ACHE systems to achieve optimal heat transfer rates, minimize energy consumption, and extend equipment lifespan.

Unlocking the Potential of ACHE Systems

As the industrial landscape continues to evolve, the demand for ACHE systems that deliver unparalleled performance, efficiency, and sustainability has never been greater. Cutting-edge technologies are ushering in a new era of industrial transformation, empowering companies to revolutionize their processes and gain a competitive edge.

Harnessing the Power of Data and Analytics

One such transformative innovation is the integration of the Industrial Internet of Things (IIoT) and advanced data analytics into ACHE systems. Startups like Hexwise are leading the charge, leveraging the power of cloud computing, big data, and artificial intelligence to optimize heat exchanger performance.

By equipping ACHEs with a network of sensors and intelligent monitoring systems, companies can gain unprecedented insights into their heat transfer processes. Real-time data on parameters such as temperature, pressure, airflow, and energy consumption can be analyzed to identify optimization opportunities, predict maintenance needs, and enhance overall system efficiency.

This data-driven approach enables industrial players to make informed decisions, optimize their ACHE operations, and unlock significant cost savings while minimizing their environmental footprint.

Advancements in Cleaning and Maintenance

Proper maintenance is crucial to ensuring the longevity and peak performance of ACHE systems. Innovative solutions, such as the patented AX Cleaner® technology from AX System, are revolutionizing the way industrial facilities approach this critical task.

The AX Cleaner® combines a high-power motor pump, a pusher, a ladder system, and high-pressure cleaning nozzles to enable efficient and thorough cleaning of air coolers. This automated system reduces the manual effort required, ensures consistent performance, and minimizes the risk of human error or safety concerns.

By empowering industrial operators to maintain their ACHEs at optimal cleanliness levels, these cutting-edge cleaning solutions help extend equipment lifespan, improve energy efficiency, and reduce the overall cost of ownership.

Embracing Sustainable Heat Transfer Solutions

As the world becomes increasingly conscious of environmental impact, the ACHE industry has responded with innovative solutions that prioritize sustainability. One such breakthrough is the rise of energy-efficient heat pump technology, which harnesses renewable energy sources like geothermal, air, or water to provide heating and cooling.

Unlike traditional HVAC systems that rely on fossil fuels, heat pumps leverage the natural transfer of heat to deliver year-round comfort while significantly reducing energy consumption and emissions. Geothermal heat pumps, in particular, have gained traction as a clean and efficient alternative, tapping into the stable temperature of the earth’s surface to meet heating and cooling needs.

These sustainable ACHE systems not only contribute to a greener future but also offer long-term cost savings for industrial facilities, making them an increasingly attractive option for companies seeking to minimize their environmental footprint.

Revolutionizing Industrial Processes with ACHE Innovation

As the industrial landscape continues to evolve, the role of air-cooled heat exchangers has become more crucial than ever. These versatile systems have the power to transform industrial processes, enhancing efficiency, reducing costs, and driving sustainability.

From data-driven optimization to innovative cleaning solutions and sustainable heat transfer technologies, the ACHE industry is at the forefront of industrial innovation. By embracing these groundbreaking advancements, companies can unlock a new era of operational excellence, positioning themselves for long-term success in an increasingly competitive and environmentally conscious market.

As an expert in this field, I encourage you to explore the vast potential of air-cooled heat exchanger systems. Whether you’re looking to enhance the performance of your existing ACHE infrastructure or considering a complete overhaul, the insights and technologies showcased in this article can serve as a guiding light on your journey toward industrial excellence.

Remember, the key to unlocking the true power of ACHEs lies in staying informed, embracing innovation, and prioritizing sustainable practices. By doing so, you can revolutionize your industrial processes, paving the way for a future of unparalleled efficiency, cost savings, and environmental stewardship.

To learn more about how https://www.aircooledheatexchangers.net/ can assist you in optimizing your ACHE systems, I encourage you to explore our comprehensive resources and connect with our team of experts. Together, we can embark on a transformative journey towards industrial excellence.

Optimizing ACHE Performance: Unlocking the Secrets

While the power of air-cooled heat exchangers is undeniable, maximizing their performance and efficiency requires a deep understanding of the intricate dynamics at play. Let’s delve into the essential factors that contribute to ACHE optimization, equipping you with the knowledge to unlock their full potential.

Mastering Airflow Management

As we’ve discussed, the management of airflow is a critical aspect of ACHE performance. Optimizing air movement can have a profound impact on heat transfer rates, energy consumption, and overall system efficiency.

One key consideration is the choice between natural draft and mechanical draft cooling towers. Natural draft towers rely on the natural buoyancy of hot air, while mechanical draft towers utilize powerful fans to force air through the exchanger. Each type offers unique advantages, and the selection should be based on factors such as available space, cooling requirements, and energy consumption.

Equally important is the configuration of the air-fluid flow within the ACHE system. Crossflow and counterflow designs present distinct advantages, with crossflow towers offering easier maintenance and lower static pressure, and counterflow towers achieving higher thermodynamic efficiency and the ability to handle larger cooling loads.

By carefully analyzing the airflow dynamics and selecting the appropriate tower configuration, you can ensure that your ACHE system operates at peak performance, maximizing heat transfer and energy efficiency.

Predictive Maintenance: Extending Equipment Lifespan

Maintaining the integrity and performance of ACHE systems is crucial, and the emergence of predictive maintenance solutions is revolutionizing this critical aspect of industrial operations.

Innovative technologies like those developed by Hexwise leverage the power of the Industrial Internet of Things (IIoT), big data analytics, and machine learning to anticipate equipment failures before they occur. By continuously monitoring key parameters such as temperature, pressure, airflow, and energy consumption, these systems can detect early warning signs of potential issues, enabling proactive maintenance and repairs.

This data-driven approach not only extends the lifespan of ACHE equipment but also minimizes downtime, reduces maintenance costs, and ensures uninterrupted process operations. By adopting predictive maintenance strategies, industrial facilities can maximize the efficiency and reliability of their air-cooled heat exchanger systems.

Sustainable Cooling Solutions: Embracing the Future

As the world becomes increasingly conscious of environmental sustainability, the ACHE industry has responded with innovative cooling solutions that prioritize energy efficiency and eco-friendliness.

One such breakthrough is the widespread adoption of heat pump technology, which harnesses renewable energy sources like geothermal, air, or water to provide heating and cooling. Unlike traditional HVAC systems that rely on fossil fuels, heat pumps leverage the natural transfer of heat, delivering year-round comfort while significantly reducing energy consumption and emissions.

Geothermal heat pumps, in particular, have emerged as a game-changer, tapping into the stable temperature of the earth’s surface to meet the heating and cooling needs of industrial facilities. These sustainable ACHE systems not only contribute to a greener future but also offer long-term cost savings, making them an attractive option for companies seeking to minimize their environmental impact.

By embracing these cutting-edge sustainable cooling solutions, industrial players can demonstrate their commitment to environmental responsibility while enjoying the benefits of increased efficiency and reduced operating costs.

Revolutionizing the Future of Industrial Processes

As the world continues to evolve, the role of air-cooled heat exchangers in the industrial landscape has become more critical than ever. These versatile systems have the power to transform industrial processes, enhancing efficiency, reducing costs, and driving sustainability.

From data-driven optimization and predictive maintenance to innovative cleaning solutions and sustainable cooling technologies, the ACHE industry is at the forefront of industrial innovation. By embracing these groundbreaking advancements, companies can unlock a new era of operational excellence, positioning themselves for long-term success in an increasingly competitive and environmentally conscious market.

As an expert in this field, I encourage you to explore the vast potential of air-cooled heat exchanger systems. Whether you’re looking to enhance the performance of your existing ACHE infrastructure or considering a complete overhaul, the insights and technologies showcased in this article can serve as a guiding light on your journey toward industrial excellence.

Remember, the key to unlocking the true power of ACHEs lies in staying informed, embracing innovation, and prioritizing sustainable practices. By doing so, you can revolutionize your industrial processes, paving the way for a future of unparalleled efficiency, cost savings, and environmental stewardship.

To learn more about how https://www.aircooledheatexchangers.net/ can assist you in optimizing your ACHE systems, I encourage you to explore our comprehensive resources and connect with our team of experts. Together, we can embark on a transformative journey towards industrial excellence.