The Rise of Intelligent Thermal Management Systems

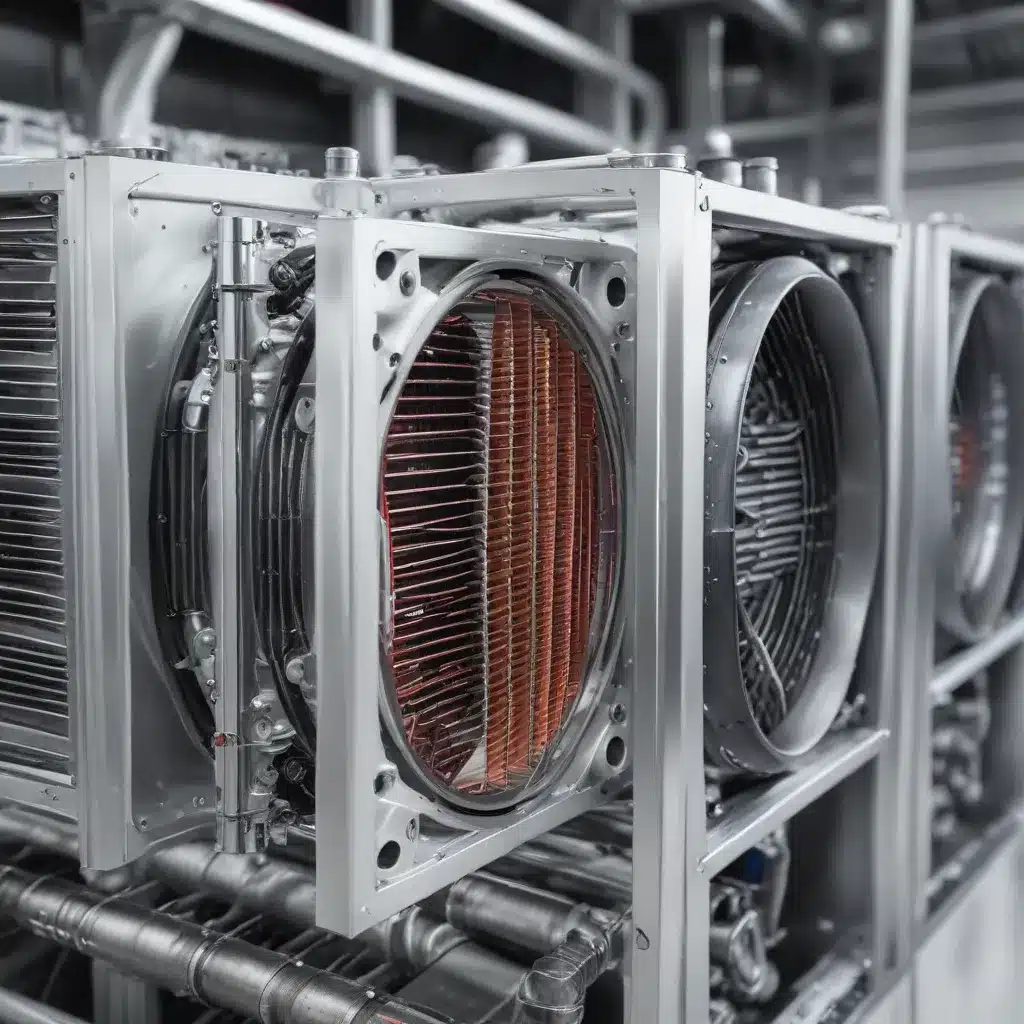

As modern industries grapple with the ever-increasing demand for efficient, reliable, and sustainable thermal management solutions, the spotlight has turned to the pivotal role of air-cooled heat exchangers. These unsung workhorses, often tucked away in the background, are now stepping into the limelight as the key to unlocking new frontiers in thermal engineering.

In the era of Industry 4.0 and the rapid growth of data-driven technologies, the need for intelligent, high-performance thermal management systems has become more critical than ever. From the data centers powering the AI revolution to the cutting-edge manufacturing facilities shaping the future, air-cooled heat exchangers are at the heart of these transformative advancements, seamlessly integrating with advanced monitoring and control systems to optimize energy efficiency, thermal performance, and overall system reliability.

Driving Innovation: Advancements in Air-Cooled Heat Exchanger Design

The air-cooled heat exchanger industry has witnessed a remarkable surge of innovation, with engineers and researchers pushing the boundaries of traditional design and materials to unlock new levels of thermal management capabilities. These advancements are reshaping the landscape, empowering industries to tackle their most pressing thermal challenges with greater precision and efficiency.

Innovative Fin Geometries and Coatings

One of the key areas of innovation lies in the design of heat exchanger fins, the intricate structures responsible for facilitating heat transfer between the air and the fluid. Through the exploration of novel fin geometries and the incorporation of advanced coatings, engineers have been able to significantly enhance the heat transfer capabilities of air-cooled heat exchangers.

Example: Researchers at the ARPA-E program have developed innovative fin designs that incorporate micro-scale features, creating a higher surface area-to-volume ratio and improving heat transfer coefficients by up to 30% compared to traditional fin designs. These advancements have enabled the creation of more compact and efficient air-cooled heat exchangers, making them increasingly suitable for applications with limited space or stringent thermal requirements.

Intelligent Monitoring and Control Systems

The integration of advanced monitoring and control systems has been a game-changer in the world of air-cooled heat exchangers. By leveraging sensors, data analytics, and sophisticated algorithms, these intelligent systems can continuously monitor and optimize the performance of the heat exchangers, ensuring optimal efficiency, reliability, and responsiveness to changing operational conditions.

Example: The https://www.aircooledheatexchangers.net/ platform has developed a comprehensive suite of air-cooled heat exchanger monitoring and control solutions, empowering operators to track key performance indicators, detect anomalies, and implement predictive maintenance strategies. This enables them to maximize the lifespan of their heat exchangers, reduce unplanned downtime, and optimize energy consumption, all while maintaining optimal thermal management capabilities.

Advancements in Materials and Manufacturing

The choice of materials and manufacturing techniques plays a crucial role in the performance and durability of air-cooled heat exchangers. Innovative materials, such as high-performance alloys and advanced composites, are being explored to enhance corrosion resistance, thermal conductivity, and structural integrity, while novel manufacturing processes, like additive manufacturing, are enabling the creation of intricate and customized heat exchanger designs.

Example: https://www.sciencedirect.com/science/article/pii/S2352152X23020911 highlights the development of a new class of aluminum alloys with enhanced thermal conductivity and corrosion resistance, making them ideal for air-cooled heat exchangers in demanding environments. These advancements, combined with the adoption of 3D printing technologies, are enabling the production of tailored heat exchanger solutions that can meet the specific needs of various industries.

Unlocking New Frontiers: Air-Cooled Heat Exchangers in Diverse Applications

The impact of these advancements in air-cooled heat exchanger technology extends far beyond the realm of traditional industrial applications. As industries continue to push the boundaries of innovation, air-cooled heat exchangers are finding their way into an ever-expanding array of cutting-edge applications, each with its own unique set of thermal management challenges.

Powering the AI Revolution: Data Centers and Generative AI

The explosive growth of data-driven technologies, particularly the rise of generative AI, has placed unprecedented demands on data center infrastructure. These AI-powered facilities require robust and efficient thermal management solutions to support the high-performance computing necessary for tasks like large language model inference and data processing.

Example: https://nvidianews.nvidia.com/news/computer-industry-ai-factories-data-centers highlights how NVIDIA’s Blackwell architecture-powered systems, featuring advanced air-cooled heat exchanger technology, are enabling the creation of “AI factories” to drive the next wave of generative AI breakthroughs. The modularity and scalability of these systems, combined with their exceptional thermal management capabilities, are transforming the way data centers approach the thermal challenges posed by the AI revolution.

Revolutionizing Industrial Manufacturing: Intelligent Thermal Control in Smart Factories

The advent of Industry 4.0 and the push for smart, automated manufacturing have introduced new thermal management challenges. Air-cooled heat exchangers are playing a pivotal role in this transformation, seamlessly integrating with advanced monitoring and control systems to optimize energy efficiency, production throughput, and equipment longevity.

Example: Taiwanese electronics giant Foxconn, one of the world’s largest makers of electronics, is planning to leverage NVIDIA’s Grace Blackwell technology to develop smart solution platforms for AI-powered electric vehicles, robotics, and language-based generative AI services. By harnessing the power of intelligent thermal management systems, Foxconn aims to provide more personalized experiences to its customers while enhancing overall operational efficiency and sustainability.

Powering the Clean Energy Transition: Air-Cooled Heat Exchangers in Renewable Energy Systems

As the world transitions towards a more sustainable future, air-cooled heat exchangers are playing a pivotal role in supporting the growth of renewable energy systems. From solar thermal power plants to geothermal energy systems, these versatile heat exchangers are helping to optimize thermal management and improve the overall efficiency of these clean energy solutions.

Example: The https://arpa-e-foa.energy.gov/ program, launched by the U.S. Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-E), is dedicated to funding innovative research and development initiatives that push the boundaries of air-cooled heat exchanger technology. These advancements are paving the way for more efficient and reliable renewable energy systems, contributing to the global effort to combat climate change and secure a sustainable energy future.

Embracing the Future: Opportunities and Challenges in Air-Cooled Heat Exchanger Technology

As the world embraces the transformative potential of intelligent thermal engineering solutions, the air-cooled heat exchanger industry finds itself at a pivotal crossroads. While the advancements in design, materials, and integrated control systems have opened up new realms of possibilities, there remain both opportunities and challenges that industry stakeholders must navigate with vigilance and expertise.

Optimizing for Energy Efficiency and Sustainability

The growing emphasis on environmental sustainability has placed a renewed focus on the energy efficiency of thermal management systems. Air-cooled heat exchangers are at the forefront of this movement, as engineers work to develop solutions that not only deliver exceptional thermal performance but also minimize energy consumption and carbon footprint.

Opportunity: The integration of advanced monitoring and control systems, coupled with the exploration of innovative fin geometries and materials, presents a significant opportunity to enhance the energy efficiency of air-cooled heat exchangers. By optimizing airflow, heat transfer, and system integration, these advancements can contribute to the broader goal of sustainable industrial operations and a greener future.

Addressing Reliability and Maintenance Challenges

Ensuring the long-term reliability and optimal maintenance of air-cooled heat exchangers is crucial, particularly in mission-critical applications where unplanned downtime can have severe consequences. Addressing these challenges requires a holistic approach that combines innovative design, robust materials, and intelligent monitoring and control systems.

Challenge: As air-cooled heat exchangers are integrated into increasingly complex and demanding systems, the need for advanced diagnostics and predictive maintenance capabilities becomes paramount. Overcoming these challenges will require close collaboration between heat exchanger manufacturers, system integrators, and end-users to develop comprehensive solutions that address the unique maintenance requirements of each application.

Fostering Collaboration and Knowledge Sharing

The rapid pace of innovation in the air-cooled heat exchanger industry necessitates a collaborative approach, where industry stakeholders, researchers, and end-users work together to drive progress and address emerging challenges.

Opportunity: Platforms like the https://www.aircooledheatexchangers.net/ blog can play a crucial role in fostering this collaborative spirit, serving as a hub for the exchange of ideas, case studies, and best practices. By facilitating knowledge sharing and cross-pollination of insights, these platforms can accelerate the adoption of cutting-edge thermal engineering solutions and empower industries to harness the full potential of air-cooled heat exchanger technology.

Conclusion: Embracing the Future of Intelligent Thermal Management

The air-cooled heat exchanger industry stands at the forefront of a new era of intelligent thermal engineering solutions. As industries across the spectrum face growing demands for efficient, reliable, and sustainable thermal management, the advancements in air-cooled heat exchanger design, materials, and integrated control systems are poised to unlock unprecedented possibilities.

From powering the AI revolution in data centers to revolutionizing smart manufacturing, and from supporting the clean energy transition to addressing mission-critical thermal challenges, air-cooled heat exchangers are proving their versatility and indispensability. By embracing these cutting-edge developments and fostering collaborative innovation, industries can unlock new frontiers of performance, efficiency, and sustainability, paving the way for a future where intelligent thermal management is the cornerstone of transformative technological progress.