Understanding the Challenges of Fouling and Scaling

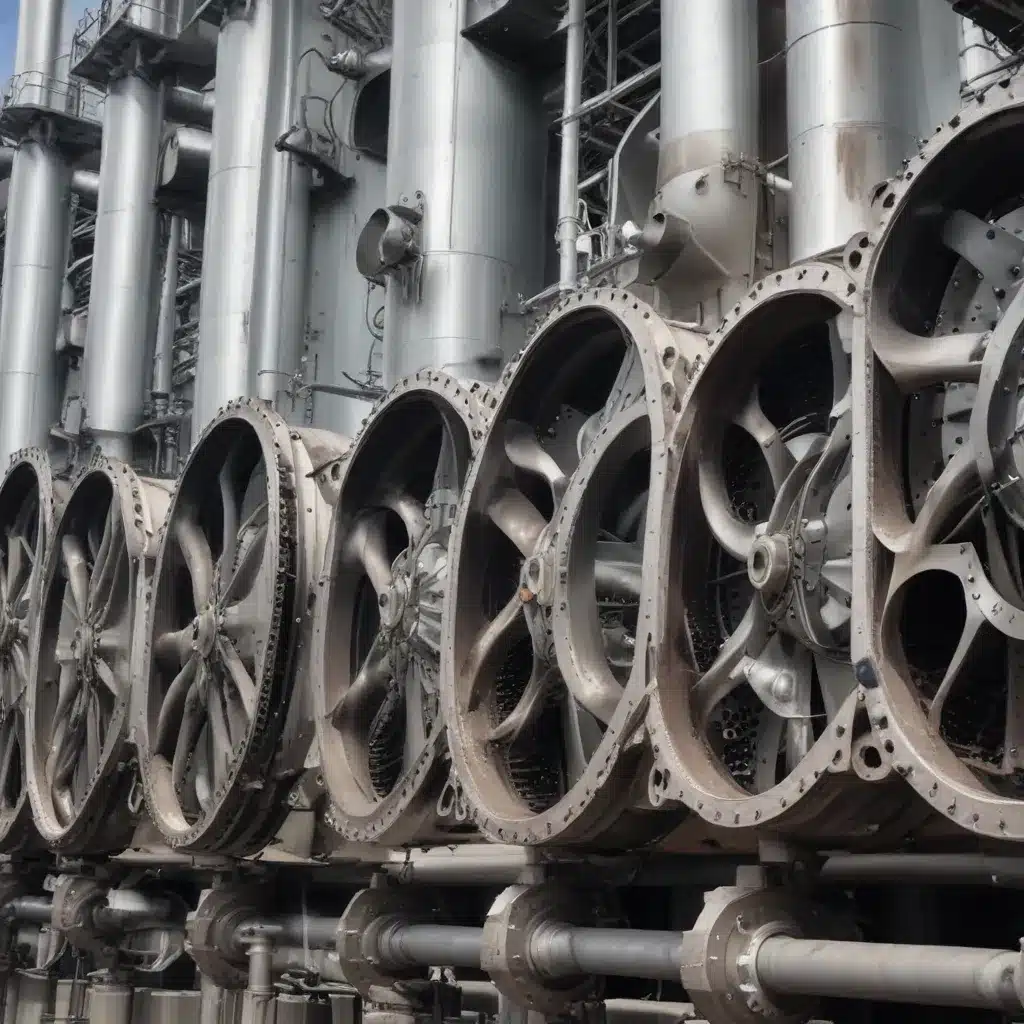

Air-cooled heat exchangers play a critical role in various industrial processes, facilitating the efficient transfer of thermal energy between fluids at different temperatures. These essential components, however, can face significant challenges over time due to factors such as corrosion, fouling, and scaling. Fouling, the accumulation of unwanted deposits on heat exchanger surfaces, and scaling, the formation of mineral scale deposits, can significantly impact the performance and lifespan of these systems.

Fouling and scaling can lead to a reduction in heat transfer efficiency, increased pressure drop, and even complete equipment failure if left unmanaged. The impacts can be far-reaching, resulting in higher energy consumption, increased maintenance costs, and potential production downtime. Understanding the mechanisms behind these issues and implementing effective mitigation strategies is crucial for maintaining the optimal performance of air-cooled heat exchangers.

Identifying the Root Causes of Fouling and Scaling

The formation of unwanted deposits on heat exchanger surfaces can stem from a variety of sources, each requiring tailored approaches for effective mitigation.

Particulate Fouling

Particulate fouling occurs when solid particles suspended in the process fluid accumulate on the heat transfer surfaces. This can be caused by the deposition of unburned fuels, ashes, dust, or other fine particulates. The severity of particulate fouling is often influenced by the size, concentration, and composition of the suspended solids.

Precipitation Fouling (Scaling)

Precipitation fouling, also known as scaling, is the result of the deposition of dissolved salts or minerals on the heat exchanger surfaces. This can happen when the process fluid becomes supersaturated with certain ions, such as calcium, magnesium, or silica, leading to the formation of insoluble mineral deposits. Factors like temperature, pH, and fluid composition can greatly affect the rate and severity of scaling.

Chemical Reaction Fouling

Chemical reaction fouling occurs when the heat exchanger surfaces interact with the process fluid, resulting in the formation of solid deposits. This can happen due to the thermal degradation of organic components or the occurrence of chemical reactions at the surface-fluid interface.

Corrosion Fouling

Corrosion fouling is a result of the reaction between the heat exchanger material and the process fluid, leading to the formation of corrosion products that can deposit on the surfaces. The presence of certain dissolved gases, pH levels, or impurities in the fluid can accelerate this process.

Biological Fouling (Biofouling)

Biological fouling, or biofouling, occurs when microorganisms, such as bacteria, algae, or fungi, accumulate and grow on the heat exchanger surfaces. This can lead to the formation of biofilms that impede heat transfer and promote the attachment of other types of fouling.

Understanding the specific mechanisms at play is crucial for selecting the right mitigation strategies and ensuring the long-term efficient operation of air-cooled heat exchangers.

Strategies for Mitigating Fouling and Scaling

Effectively managing fouling and scaling in air-cooled heat exchangers requires a multifaceted approach, combining both preventive and remedial measures. Here are some key strategies to consider:

Design Considerations

Incorporating fouling-resistant features into the design of air-cooled heat exchangers can help mitigate the impact of fouling and scaling. Strategies include:

- Selecting materials with low surface energy or corrosion resistance to discourage the adherence of deposits.

- Optimizing flow velocities to enhance shear forces and prevent the accumulation of particles.

- Utilizing compact fin designs or fluidized bed heat exchangers to disrupt boundary layers and promote deposit removal.

- Providing easy access for cleaning and maintenance to facilitate the removal of accumulated deposits.

Operational Optimization

Adjusting the operating parameters of air-cooled heat exchangers can help minimize fouling and scaling:

- Maintaining high flow velocities, especially in critical areas, to increase the shear forces and dislodge deposits.

- Controlling the temperature of the heat exchanger surfaces to avoid conditions that favor the precipitation of salts or minerals.

- Implementing regular cleaning schedules, both online and offline, to remove accumulated deposits before they become problematic.

- Carefully monitoring and adjusting the pH, chemical composition, and other relevant parameters of the process fluid to prevent fouling and scaling.

Chemical Mitigation Techniques

The use of chemical additives can be an effective strategy for mitigating fouling and scaling in air-cooled heat exchangers:

- Employing sequestering agents, such as EDTA, to complex with and prevent the precipitation of scale-forming ions.

- Utilizing threshold inhibitors, like polyphosphates or polyphosphonates, to interfere with the nucleation and growth of crystalline deposits.

- Applying dispersants to keep particulate matter suspended in the fluid and prevent their deposition on heat exchanger surfaces.

- Leveraging corrosion inhibitors to protect the metal surfaces and minimize the formation of corrosion-related fouling.

Mechanical Cleaning Methods

Complementing chemical methods, mechanical cleaning techniques can be used to physically remove accumulated deposits from air-cooled heat exchanger surfaces:

- Implementing online cleaning systems, such as sponge ball or brush cleaning, to continuously dislodge deposits without disrupting operations.

- Utilizing off-line cleaning methods, including high-pressure water jets, lances, or abrasive tools, to thoroughly remove stubborn fouling and scaling deposits during scheduled maintenance.

- Employing ultrasonic or vibration-based cleaning technologies to disrupt the adhesion of deposits and facilitate their removal.

Emerging Fouling Mitigation Techniques

Researchers and industry professionals are continuously exploring innovative approaches to address the challenges of fouling and scaling in air-cooled heat exchangers:

- Investigating the use of advanced surface coatings or treatments to reduce the propensity for deposit formation.

- Evaluating the potential of electromagnetic or pulsed electric field technologies to disrupt the crystallization and adhesion of mineral scales.

- Exploring the application of biofouling-resistant materials or coatings to prevent the growth of microorganisms on heat exchanger surfaces.

Optimizing the Performance and Longevity of Air-Cooled Heat Exchangers

Mitigating fouling and scaling in air-cooled heat exchangers is a multifaceted challenge that requires a comprehensive approach. By understanding the root causes of these issues, leveraging design strategies, optimizing operational parameters, and employing both chemical and mechanical cleaning methods, air-cooled heat exchanger operators can maintain peak performance, minimize downtime, and extend the lifespan of these critical components.

Regular monitoring, proactive maintenance, and a willingness to adopt innovative fouling mitigation techniques are key to ensuring the reliable and efficient operation of air-cooled heat exchangers in diverse industrial applications. By addressing the challenges of fouling and scaling, businesses can optimize their processes, reduce energy consumption, and ultimately enhance their overall productivity and profitability.

For more information on air-cooled heat exchanger maintenance, design, and troubleshooting, please visit https://www.aircooledheatexchangers.net/.