Mastering the Fundamentals of Heat Transfer

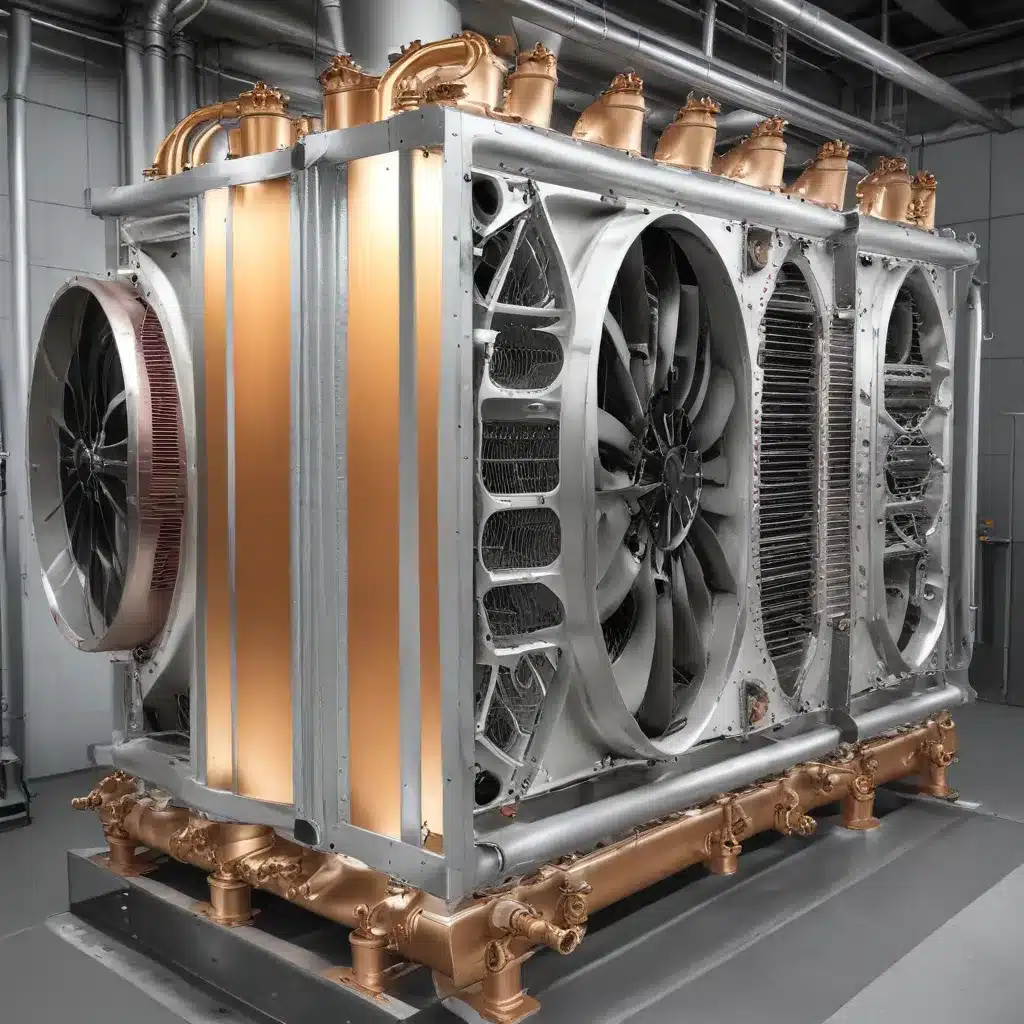

Effective thermal management is the cornerstone of ensuring optimal performance and reliability across a wide range of industries. From powering our electronic devices to regulating the temperature in our buildings, the ability to efficiently dissipate heat is critical. At the heart of many thermal management solutions lies the air-cooled heat exchanger – a passive cooling device that absorbs and dissipates excess heat through the principles of conduction, convection, and radiation.

Understanding the underlying physics of heat transfer is essential for designing and optimizing air-cooled heat exchanger performance. Conduction refers to the transfer of thermal energy through direct contact between materials, where heat flows from areas of higher temperature to areas of lower temperature. Convection involves the movement of heat through fluids, such as air or water, which can be either natural (driven by buoyancy) or forced (aided by external means like fans or pumps). Radiation is the emission of electromagnetic waves, which allows heat to be transferred without the need for a physical medium.

By harnessing these fundamental principles of heat transfer, engineers can create innovative air-cooled heat exchanger designs that efficiently dissipate thermal energy and maintain optimal operating conditions for a wide range of applications. Whether it’s keeping electronics cool, regulating temperature in buildings, or managing the heat generated by industrial processes, air-cooled heat exchangers play a crucial role in thermal management.

Overcoming Thermal Management Challenges

As technology advances and systems become increasingly compact and powerful, the challenges facing thermal management solutions have intensified. One of the primary hurdles is the need to dissipate ever-increasing heat densities within limited space constraints. As electronic devices and machinery become more advanced, they generate more heat in smaller footprints, putting strain on traditional cooling methods.

Another key challenge is the diverse temperature thresholds of various system components. Each part within a larger system may have distinct operating temperature requirements for optimal performance and longevity. Thermal management strategies must be carefully designed to meet the specific needs of each element, ensuring they operate within their designated temperature ranges and avoiding overheating of sensitive components.

Engineers have developed a range of innovative techniques to address these thermal management challenges, including the use of heat pipes, advanced thermal interface materials (TIMs), and liquid cooling systems. Heat pipes, for example, leverage the principles of phase change and capillary action to efficiently transfer heat from the source to the heat sink. TIMs, on the other hand, improve thermal conductivity between mating surfaces, reducing thermal resistance and facilitating more effective heat dissipation.

Liquid cooling systems have also emerged as a popular solution, particularly in high-power applications. By utilizing liquid coolants such as water or specialized fluids, these systems offer superior heat removal capabilities compared to traditional air cooling. However, air-cooled heat exchangers remain a widely used and cost-effective option for many applications, especially those with lower power densities.

Optimizing Air-Cooled Heat Exchanger Design and Performance

Designing and optimizing air-cooled heat exchangers requires a multifaceted approach that considers various factors, including heat sink geometry, material selection, and airflow management. Heat sink design is a critical aspect, as the size, shape, and material properties of the heat sink directly impact its ability to dissipate heat.

Finned heat sinks are a common solution, as they increase the surface area available for heat transfer and provide pathways for convective cooling. The strategic placement of these fins, as well as their overall dimensions, can significantly influence the heat exchanger’s thermal performance. Additionally, the choice of heat sink material, such as metals with high thermal conductivity, plays a vital role in efficient heat dissipation.

Thermal interface materials also play a crucial role in enhancing heat transfer between the heat source and the heat sink. These materials, which can take the form of grease, pads, or phase-change materials, fill microscopic gaps between mating surfaces, reducing thermal resistance and improving overall heat transfer efficiency.

Airflow management is another key consideration in air-cooled heat exchanger design. Fans or blowers can be employed to create forced convection, augmenting heat dissipation from the heat sink and other components. The strategic placement and sizing of these active cooling systems, as well as the design of the enclosure or housing, can significantly impact the heat exchanger’s overall cooling performance.

Thermal Management in Specific Applications

The importance of effective thermal management extends across a wide range of industries and applications. Let’s explore a few examples where air-cooled heat exchangers play a crucial role in maintaining optimal performance and reliability.

Motor Drives

Motor drives, also known as motor controllers or inverters, are electronic devices that control the speed, torque, and direction of electric motors. Thermal management is critical in motor drives due to the significant heat generated during operation, primarily from power losses in semiconductor devices and other components. Effective heat dissipation is essential to maintain the motor drive’s performance and lifespan, preventing degradation and potential component failures.

In motor drive applications, heat sink design is paramount for efficient heat dissipation from the power electronics. Finned heat sinks, strategically sized and shaped, increase the surface area for heat transfer and provide pathways for convective cooling. Thermal interface materials further enhance the thermal contact between the semiconductor devices and the heat sink, reducing thermal resistance.

Fans or blowers can be employed as active cooling systems to augment heat dissipation, especially in enclosed or high-temperature environments. Alternatively, liquid cooling systems may be utilized in high-power motor drives, circulating coolant through channels or heat exchangers to provide efficient heat removal.

Graphics Processing Units (GPUs)

Graphics processing units (GPUs) have become an integral part of modern computing, driving advancements in gaming, scientific computing, artificial intelligence, and cryptocurrency mining. These highly parallel processing units generate significant amounts of heat during operation, which must be effectively dissipated to maintain optimal performance and reliability.

Cooling solutions for GPUs typically involve a combination of built-in fans and heatsinks, as well as aftermarket upgrades and optimized case airflow. Upgrading to larger heatsinks and more powerful fans can enhance heat dissipation, while the use of premium thermal interface materials can further improve heat transfer efficiency.

In high-performance applications, advanced cooling techniques, such as liquid cooling or hybrid solutions that combine air and liquid cooling, provide superior thermal management for GPUs. These systems effectively transfer heat away from the GPU die and other critical components, ensuring consistent performance and prolonged lifespan.

Computational Fluid Dynamics (CFD) and Simulation

In the realm of engineering, computer-aided design (CAD) and advanced simulation techniques play a pivotal role in the design and optimization of thermal management systems, including air-cooled heat exchangers. CAD software allows engineers to create and visualize the precise geometry of heat exchangers, while simulation tools, such as Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD), enable the modeling and analysis of heat transfer behavior, temperature distributions, and fluid dynamics.

The integration of CAD and simulation techniques enables engineers to validate their designs, optimize thermal performance, and ensure the heat exchanger meets the desired specifications. This iterative design process allows for the exploration of different geometries, materials, and operating conditions, ultimately leading to more efficient and effective thermal management solutions.

The insights gained from CAD and simulation are particularly valuable in industries such as electronics, automotive, aerospace, and power generation, where precise temperature control is critical for maintaining system performance and reliability.

The Rise of Artificial Intelligence in Thermal Management

The growing influence of artificial intelligence (AI) has extended to the field of thermal management, offering new opportunities for optimizing air-cooled heat exchanger design and operation. By harnessing the power of advanced analytics and optimization algorithms, AI-driven approaches can provide engineers with deep insights into thermal behavior, identify patterns, and make data-driven decisions to enhance the efficiency of thermal management systems.

AI-powered analytics can process vast amounts of data related to heat dissipation, temperature profiles, and system performance, enabling a comprehensive understanding of the underlying thermal dynamics. This information can inform the design of more efficient heat exchangers, optimize airflow patterns, and provide predictive maintenance recommendations to ensure consistent and reliable performance.

Furthermore, the integration of AI with generative design techniques can revolutionize the way engineers approach heat exchanger development. By leveraging AI algorithms to explore the design space and generate innovative geometries, engineers can create air-cooled heat exchangers that push the boundaries of thermal management, offering enhanced heat transfer capabilities, reduced size and weight, and improved overall system efficiency.

As the demand for thermal management solutions continues to grow, the convergence of cutting-edge technologies, such as additive manufacturing, simulation, and artificial intelligence, will play a crucial role in the development of next-generation air-cooled heat exchangers. By embracing these innovative approaches, engineers can unlock new possibilities in thermal management, enabling more compact, efficient, and reliable systems that address the ever-evolving challenges in various industries.

Conclusion

Effective thermal management is a fundamental pillar of modern engineering, ensuring the optimal performance and longevity of a wide range of systems and devices. At the heart of many thermal management solutions lies the air-cooled heat exchanger, a passive cooling device that harnesses the principles of conduction, convection, and radiation to dissipate excess heat.

As technology continues to advance, the challenges facing thermal management have intensified, with the need to dissipate ever-increasing heat densities within limited space constraints and accommodate diverse temperature thresholds across system components. Engineers have risen to these challenges, developing innovative techniques such as heat pipes, advanced thermal interface materials, and liquid cooling systems to enhance heat transfer efficiency.

The design and optimization of air-cooled heat exchangers require a multifaceted approach that considers factors like heat sink geometry, material selection, and airflow management. These principles are applied across various industries, including motor drives, graphics processing units, and computational fluid dynamics, where effective thermal management is crucial for maintaining optimal performance and reliability.

Looking to the future, the integration of cutting-edge technologies, such as additive manufacturing, simulation, and artificial intelligence, is poised to revolutionize the field of thermal management. By leveraging these innovative approaches, engineers can create air-cooled heat exchangers that push the boundaries of what is possible, offering enhanced thermal performance, reduced size and weight, and improved overall system efficiency.

As the demand for thermal management solutions continues to grow, the insights and strategies outlined in this article will serve as a valuable resource for engineers and industry professionals seeking to optimize the design and operation of air-cooled heat exchangers. By embracing these innovative approaches, we can unlock new possibilities in thermal management, paving the way for a more efficient, reliable, and sustainable future.

Visit https://www.aircooledheatexchangers.net/ to learn more about the latest advancements in air-cooled heat exchanger technology and explore how these solutions can benefit your industry.

Key Takeaways

- Effective thermal management is crucial for ensuring optimal performance and reliability across a wide range of industries.

- Air-cooled heat exchangers play a vital role in dissipating excess heat through the principles of conduction, convection, and radiation.

- As technology advances, the challenges facing thermal management have intensified, requiring innovative solutions such as heat pipes, advanced thermal interface materials, and liquid cooling systems.

- Designing and optimizing air-cooled heat exchangers involves considering factors like heat sink geometry, material selection, and airflow management.

- Air-cooled heat exchangers have applications in various industries, including motor drives, graphics processing units, and computational fluid dynamics.

- Emerging technologies, such as additive manufacturing, simulation, and artificial intelligence, are revolutionizing the field of thermal management, enabling the creation of more efficient, compact, and reliable air-cooled heat exchangers.